1. What are the characteristics of Monel 400?

Resistant to seawater and steam at high temperatures

Excellent resistance to rapidly flowing brackish water or seawater

Excellent resistance to stress corrosion cracking in most freshwaters

Particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated

Offers some resistance to hydrochloric and sulfuric acids at modest temperatures and concentrations, but is seldom the material of choice for these acids

Excellent resistance to neutral and alkaline salt

Resistance to chloride induced stress corrosion cracking

Good mechanical properties from sub-zero temperatures up to 1020° F

High resistance to alkalis

2. Chemical Composition, %

|

C

|

Mn

|

S

|

Si

|

Ni

|

Cu

|

Fe

|

|

.30 max

|

2.00 max

|

.024 max

|

.50 max

|

63.0 min

|

28.0-34.0

|

2.50 max

|

3. Corrosion Resistant Monel 400

Alloy 400 is virtually immune to chloride ion stress corrosion cracking in typical environments. Generally, its corrosion resistance is very good in reducing environments, but poor in oxidizing conditions. It is not useful in oxidizing acids, such as nitric acid and nitrous. Nevertheless, it is resistant to most alkalis, salts, waters, food products, organic substances and atmospheric conditions at normal and elevated temperatures.

This nickel alloy is attacked in sulfur-bearing gases above approximately 700° F and molten sulfur attacks the alloy at temperatures over approximately 500° F.

Monel 400 offers about the same corrosion resistance as nickel but with higher maximum working pressures and temperatures and at a lower cost due to its superior ability to be machined.

4. In what applications is Monel 400 used?

Marine engineering

Chemical and hydrocarbon processing equipment

Gasoline and freshwater tanks

Crude petroleum stills

De-aerating heaters

Boiler feed water heaters and other heat exchangers

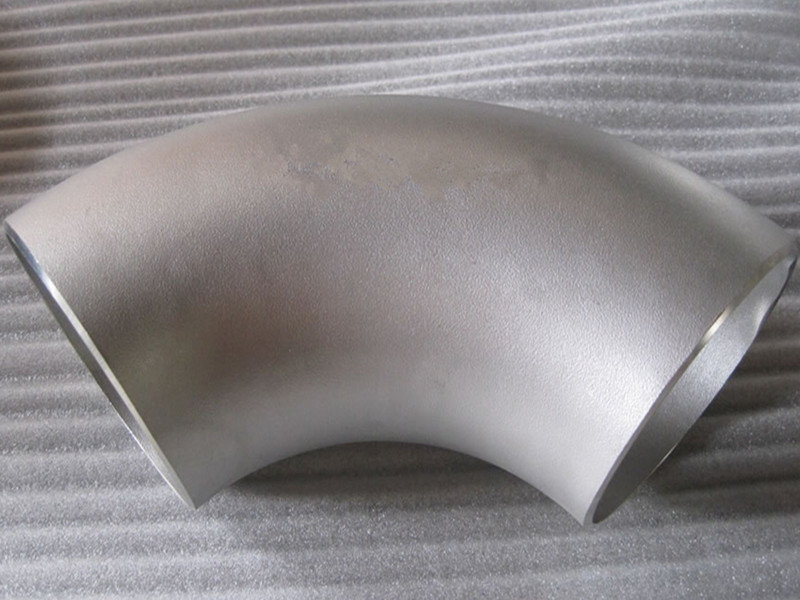

Valves, pumps, shafts, fittings, and fasteners

Industrial heat exchangers

Chlorinated solvents

Crude oil distillation towers

5. Fabrication with Monel 400

Alloy 400 can easily be welded by gas-tungsten arc, gas metal arc or shielded metal arc processes using appropriate filler metals. There is no need for post weld heat treatment, however, thorough cleaning after welding is critical for optimum corrosion resistance, otherwise there is the risk of contamination and embrittlement.

Finished fabrications can be produced to a wide range of mechanical properties when proper control of the amount of hot or cold working and the selection of appropriate thermal treatments is done.

Like most other nickel alloys, Monel 400 is typically tough to machine and will work harden. However, excellent results can e obtained if you make the correct choices for tooling and machining.

6. ASME B366 Standard

ASME SB366/ASTM

B366 |

Standard Specification for Factory-Made Wrought Nickel and Nickel Alloy Fittings |

| Material Grade |

UNS N02200 /WPN/CRN |

UNS N02201 /WPNL/CRNL |

UNS N04400 /WPNC/CRNC |

UNS N06002 /WPHX/CR HX |

UNS N06007 /WPHG/CR HG |

| UNS N06022 /WPHC22/CR HC22 |

UNS N06025 /WPV602/CRV602 |

UNS N06030 /WPHG30/CR HG30 |

UNS N06045 /WPV45TM/CRV45TM |

UNS N06059 /WP5923/CR5923 |

| UNS N06200 /WHC2000/CR HC2000 |

UNS N06230 /WPH230/CRH230 |

UNS N06455 /WPHC4/CR HC 4 |

UNS N06600 /WPNCI/CRNCI |

UNS N06603 /WP603GT/CR603GT |

| UNS N06625 /WPNCMC/CRNCMC |

UNS N06985 /WPHG3/CR HG3 |

UNS N08020 /WP20CB/CR20CB |

UNS N08904 /WP904L/CR904L |

UNS N08031 /WP3127/CR3127 |

| UNS N08120 /WPH120/CRH120 |

UNS N08330 /WP330/CR330 |

UNS N08367 /WP6XN/CR6XN |

UNS N08800 /WPNIC/CRNIC |

UNS N08810 /WPNIC10/CRNIC10 |

| UNS N08811 /WPNIC11/CRNIC11 |

UNS N08825 /WPNICMC/CRNICMC |

UNS N08925 /WP1925/CR1925 |

UNS N08926 /WP1925N/CR1925N |

UNS N10001 /WPHB/CR HB |

| UNS N10003 /WPHN/CR HN |

UNS N10276 /WPHC276/CR HC 276 |

UNS N10629 /WPVB4/CRVB4 |

UNS N10665 /WPHB-2/CR HB2 |

UNS N10675 /WPHB-3/CR HB3 |

| UNS N12160 /WPH160/CRH160 |

UNS R20033 /WP3033/CR3033 |

UNS R30556 /WPH556/CRH556 |

|

|

| Product Form |

| ASME B16.9 |

Size:1/2"-48" Wall thickness:SCH5S-SCHXXS |

| ASME B16.28 |

Size:1/2"-24" Wall thickness:SCH5S-SCHXXS |

| MSS SP43 |

Size:1/2"-24" Wall thickness:SCH5S-SCHXXS |

| MSS SP75 |

Size:16"-60" Wall thickness:SCH5S-SCHXXS |