ASTM A312 UNS S31254 STAINLESS STEEL WELDED PIPES, ASTM A312 SMO 254 STAINLESS STEEL seamless PIPES, ASTM A312 1.4547 STAINLESS STEEL WELDED PIPES, uns s31254 STAINLESS STEEL WELDED PIPES supplier, ASTM A312 ALLOY 254 STAINLESS STEEL WELDED PIPES, ASTM A269 254SMO stainless steel tubes factory in China HT PIPE.

254SMO stainless steel is a high end, molybdenum and nitrogen alloyed super austenitic stainless steel with low carbon content. With high levels of chromium, molybdenum, and nitrogen, Alloy 254 SMO is frequently used in high chloride environments, such as brackish water, seawater, pulp mill bleach plants, and other chloride process streams. It demonstrates outstanding resistance to pitting, crevice corrosion stress cracking, and corrosion fatigue uniform corrosion.

We Supply ASTM A312

UNS S31254 Stainless Steel Welded Pipes in Grades in Specification ASME SA / ASTM A269, A312, A213 and Grades 304, 304L, 304H, 304LN, 309s, 310s, 316, 316L, 316H, 316Ti, 316LN, 317L, 321, 321H, 347, 347H, 904L, 254 SMO, 6MO, 6 MOLY, UNS S31254 etc. HT PIPE export ASTM A312 SMO 254 Stainless Steel seamless and Welded Pipes and prefabracation pipe spools in various countries like Iran, Iraq, Kuwait, Saudi Arabia, Oman, UAE, Singapore, Malaysia, Indonesia, South korea, Chile, Peru, Venezuela, Australia, Netherlands, Brazil, Norway, United Kingdom, Mexico, Canada etc.

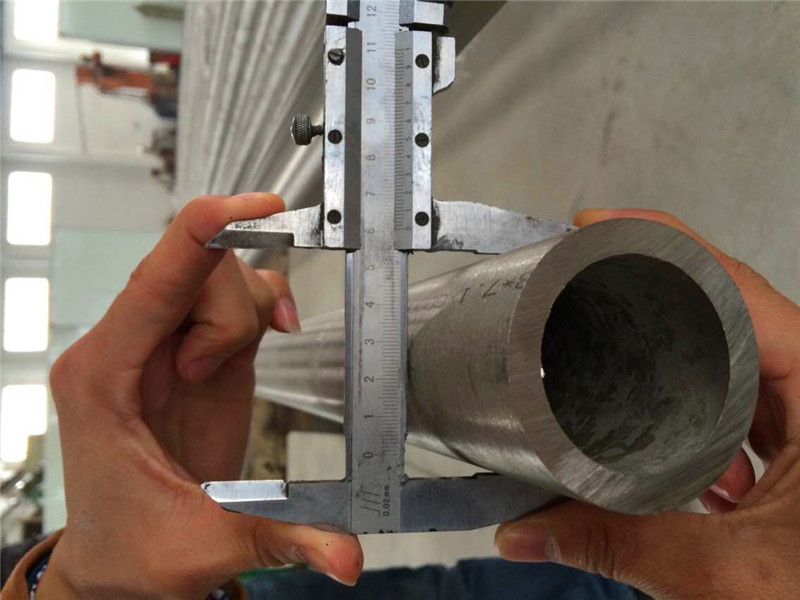

SMO 254 stainless steel Seamless Pipes Specifications

| Specifications |

ASTM A 312 ASME SA 312, ASTM A 213 ASME SA 213, ASTM A269 ASME SA 269 |

| Dimensions |

ASTM, ASME and API |

| Size |

3/4″ – 12″ |

| Specialized in |

Large Diameter Size |

| Thickness |

20 Swg., 18 Swg., 16 Swg., 14 Swg., 12 Swg., 10 Swg., & Sch. 10, Sch. 40, Sch. 80 etc. |

| Type |

Seamless / ERW / Welded / Fabricated |

| Form |

Round, Square Etc |

| Length |

Single Random, Double Random & Cut Length. |

| End |

Plain End, Beveled End, Treaded |

S31254 stainless steel welded Pipes Chemical Composition

| SMO 254 |

Ni |

C |

Mo |

Mn |

Si |

Fe |

Cu |

S |

P |

Cr |

| 17.5 – 18.5 |

0.02 max |

6 – 6.5 |

1 max |

0.8 max |

– |

0.5 – 1 |

0.01 max |

0.03 max |

19.5 – 20.5 |

SMO 254 Pipe Mechanical Properties

| Density |

Melting Point |

Yield Strength (0.2%Offset) |

Tensile Strength |

Elongation |

| 8.0 g/cm3 |

1320-1390 ℃ |

300 |

650 |

35 % |

Equivalent Grades for 254SMO stainless steel Pipe

| STANDARD |

UNS |

WERKSTOFF NR. |

AFNOR |

EN |

JIS |

SIS |

GOST |

| SMO 254 |

S31254 |

1.4547 |

Z1 CNDU 20.18.06Az |

X1CrNiMoCuN20-18-7 |

– |

2378 |

– |

UNS S31254 254 SMO Pipes Test Certificates

• EN 10204/3.1B,

• Raw Materials Certificate

• 100% Radiography Test Report

• Third Party Inspection Report, etc

254smo materials Application fields:

1. Ocean: marine structures, seawater desalination, seawater farming, seawater heat exchange, etc.

2. Environmental protection field: flue gas desulfurization device for thermal power generation, waste water treatment, etc.

3. Energy field: nuclear power generation, comprehensive utilization of coal, tidal power generation, etc.

4. Petrochemical field: oil refining, chemical and chemical equipment, etc.

5. Food field: salt making, soy sauce brewing, etc.

6. High concentration chloride ion environment: paper industry, various bleaching devices