ステンレス鋼板・シート・コイル

インコネル 601 2.4851 ボルトねじ付きボルト DIN975 ボルト M8 M6 M10 M12 M16 M20 高品質ベストプライス

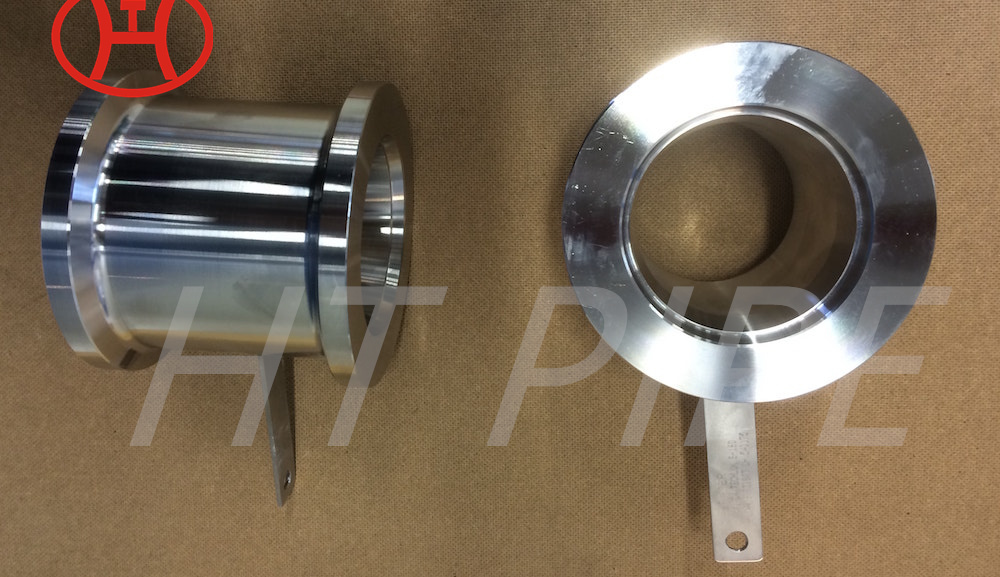

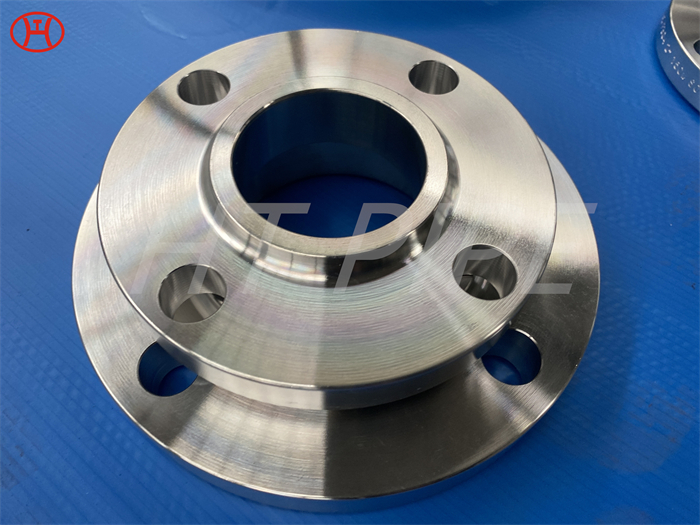

ニッケル 200 フランジ ニッケル 200 フランジは耐久性があり、寸法が安定しており、仕上げが優れています。さらに、ASTM B564 UNS N02200 ブラインド フランジは、中性および酸化環境での耐腐食性を備えているため、食品取り扱い機器での使用に最適です。

パシュトゥー語

ニッケルベースの 800 インコロイ六角パイプは、耐食性に優れていることが知られています。具体的には、インコロイ 800 パイプは浸炭と酸化腐食の両方に対して十分な耐性を備えています。\/5 に基づく壁厚が 4 mm を超える場合は、プレーン エンド (PE) またはベベル エンド (BE) の両方の準備で提供できます。

パシュトゥー語

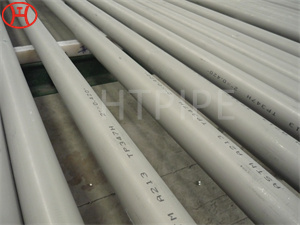

グレード 904L SS は、実際には炭素含有量が低い非安定化オーステナイト SS です。この合金は、硫酸などの強還元酸に対する耐性を向上させるために、ステンレス鋼に銅を添加したものです。 904Lシームレスパイプは応力腐食割れや隙間腐食に対する耐性に優れています。 WNR 1.4539 904L も非磁性であり、靭性、溶接性、成形性を備えています。このグレードには、ニッケルやモリブデン合金などの高価な成分が大量に含まれています。現在、ほとんどの用途ではこのグレードが要求されており、別の合金に置き換えられています。このグレードの製品はSS904Lパイプ形式で提供されます。

HT PIPE は、SS 904L パイプのような非常に高品質の製品を最も多く取り揃えている著名なメーカー、サプライヤーの 1 つです。 UNS N08904 パイプは、あらゆる用途の要求を十分に満たせるよう、包括的な製品ラインナップで提供されています。それぞれの購入者にとって、製品はカスタムメイドの仕様、規格、寸法などで入手可能です。つまり、購入者はステンレス鋼 904L 作品を番号 1 から入手できるように注文できることを意味します。ニーズや要件に応じて、さまざまな壁の厚さ、長さ、タイプ、スケジュール、サイズ、端部、形状などの 1.4539 パイプ。 904l ステンレス鋼チューブは市場をリードする価格で入手可能です。

パシュトゥー語

|

電話番号: |

リンク: |

ラオ語 |

ん |

ホーム |

タイ語 グルジア語 |

ウルドゥー語 カザフ語 |

イボ語 |

シ |

ズールー語 |

|

エスペラント語 |

ジャワ語 |

モンゴル語 |

マラヤーラム語 |

チチェワ |

19.0–23.0 |

23.0–28.0 |

4.0–5.0 |

マダガスカル |

1.00–2.00 |

パシュトゥー語

ニッケル合金ファスナー

|

引張強さ: |

リトアニア語 |

|

合金鋼フランジ |

ベトナム語 |

|

ニロ \/ 合金 K W.Nr.: 1.3981 |

35% |

|

二相鋼管 |

ベラルーシ語 |