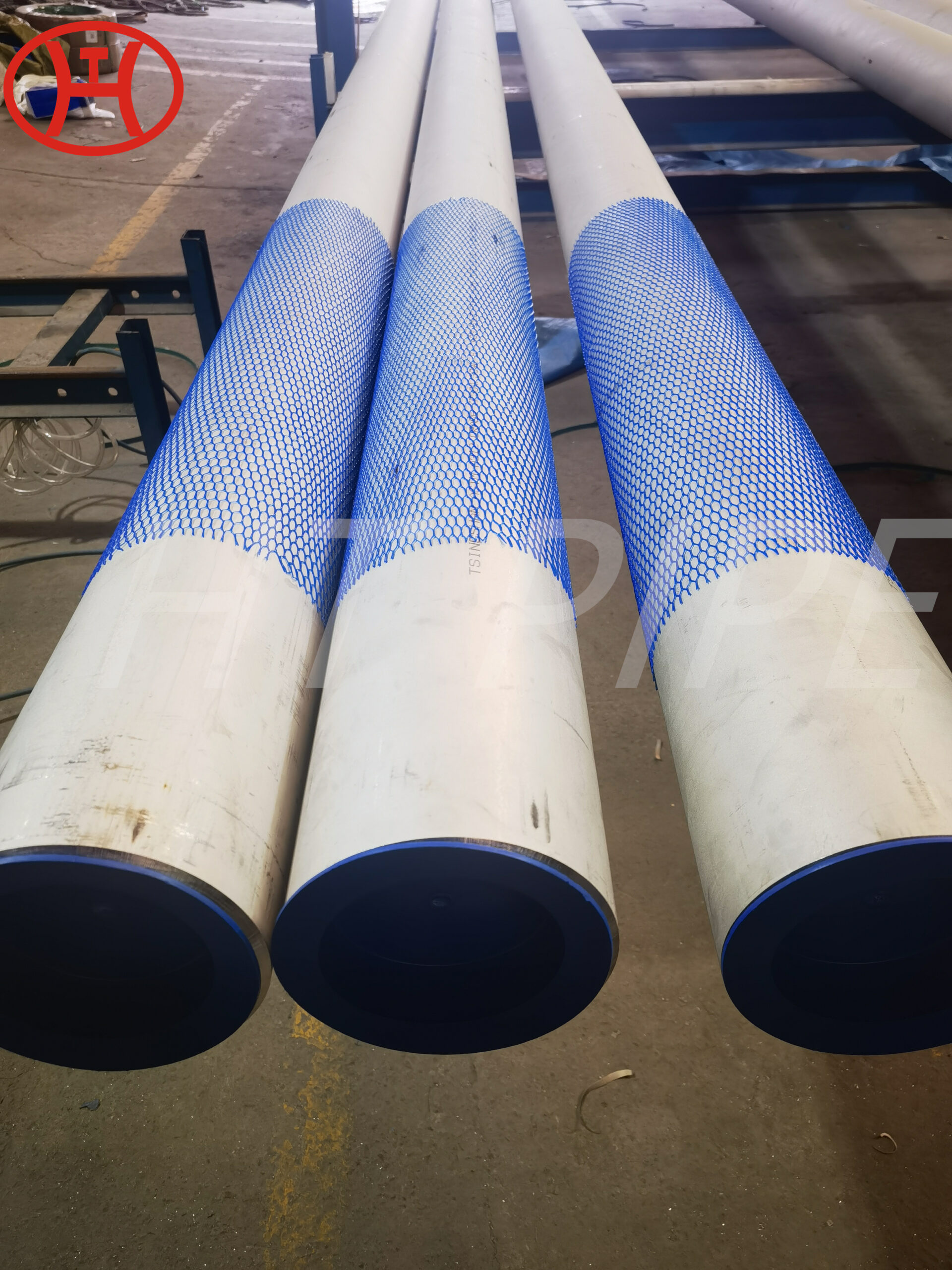

18 inch seamless steel pipes seamless nickel alloy tubes

Nickel based alloys are very useful materials for making high quality nickel alloy seamless pipes. This is one of the main reasons that it offers excellent corrosion resistance in both waterborne and high temperature applications and is very ductile. It can be electroplated and is easy to solder, which makes it suitable for industries where very high and low temperatures come into play.

Nickel-Cobalt Alloys Welded & Polished Pipes, 4 inch ASTM B161 Nickel Seamless Pipes stockist in China

Nickel tube is a metal tube made of an alloy whose composition mainly contains nickel and other elements. Seamless nickel alloy tubes are usually cold drawn and have less absolute roughness. The seamless nature results in a very uniform surface, which results in a uniform wall thickness along the length of the pipe. There are alloy nickel tubes and pure alloy tubes.

Also, pure nickel pipe is actually commercially pure and contains about 99% nickel in the composition. Nickel welded pipe is ideal for welding needs. Nickel is inherently very corrosion resistant and lightweight. These attributes of elements are used in various applications.

Nickel alloy pipe also features superior high-temperature strength, corrosion resistance and heat resistance. The material can be used under harsh environments where general stainless steel and heat resistant steel cannot be used.

The nickel alloy pipe is mainly used in airplanes as well as chemical, petrochemical and nuclear power plants.

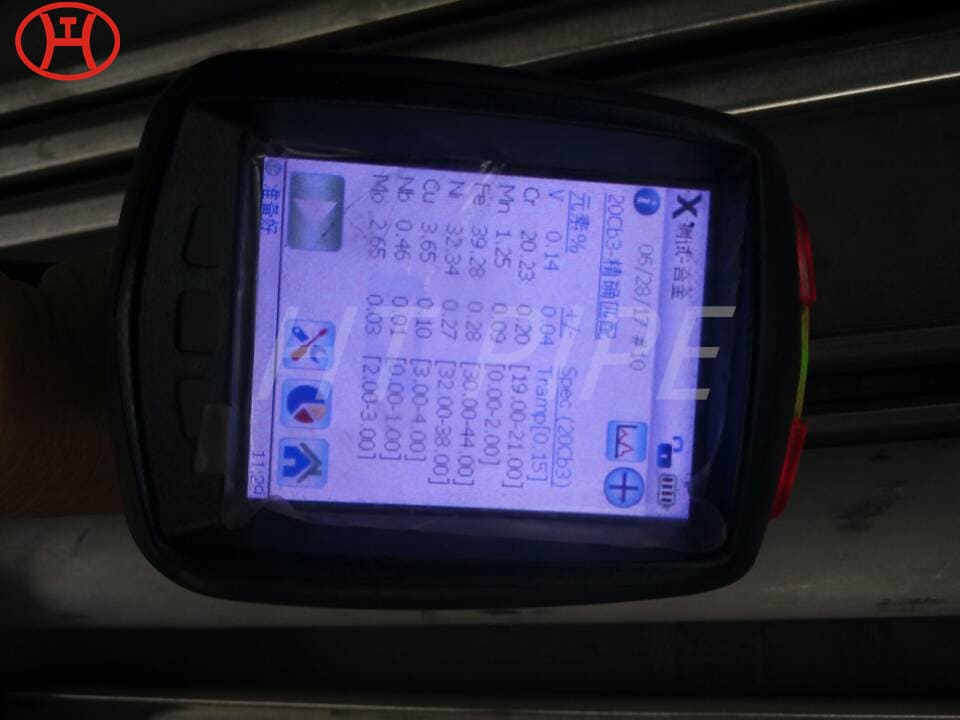

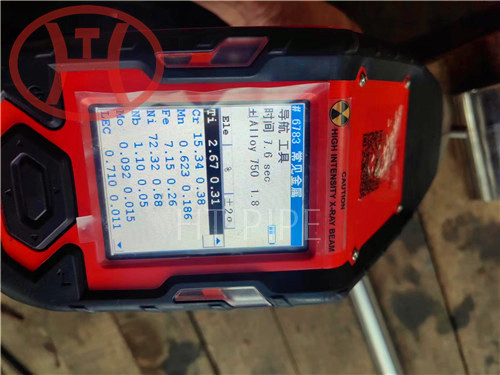

HT PIPE responds to diversified needs of customers through mass production by electric furnaces and a small amount of special melting by VAR and ESR.

At the same time, the corrosion resistance of nickel-containing alloy pipe can be used in a wide range of energy applications – from renewables to fossil fuels. Even as society shifts to renewable energy, there is still a need for oil and gas today.

| Alloy | UNS | Description |

|---|---|---|

| 200 | N02200 | This alloy provides highly ductile mechanical properties across a wide temperature range. |

| 825 | N08825 | An austenitic nickel-iron-chromium-molybdenum-copper alloy providing high levels of corrosion resistance. |

| 201 | N02201 | This alloy provides highly ductile mechanical properties across a wide temperature range. |

| ALLOY 20 | N08020 | This alloy has excellent resistance to general corrosion, pitting, and crevice corrosion in chemicals containing chlorides and sulfuric, phosphoric, and nitric acids. |

| 400 | N04400 | A ductile nickel-copper alloy with resistance to a variety of corrosive conditions. |

| ALLOY 22 | N06022 | A Ni-Cr-Mo alloy that provides outstanding resistance to pitting, crevice corrosion, intergranular attack, and stress corrosion cracking. |

| 600 | N06600 | Nickel Chromium alloy designed for use from cryogenic to 2000°F. It is non-magnetic and readily weldable. |

| ALLOY 59 | N06059 | This alloy is a nickel-chromium-molybdenum alloy with an extra-low carbon and silicon content. |

| 601 | N06601 | An austenitic nickel-chromium-iron alloy designed for both heat and corrosion resistance. |

| B-2 | N10665 | This alloy is a solid solution strengthened, nickel-molybdenum alloy, typically used in extreme reducing conditions. |

| 625 | N06625 | An austenitic nickel-base super alloy possessing excellent resistance to oxidation and corrosion over a broad range of corrosive conditions. |

| C276 | N10276 | A nickel-molybdenum-chromium-iron-tungsten alloy which is among the most corrosion resistant of alloys currently available. |

| 686 | N06686 | An alloy designed for outstanding corrosion resistance in a wide range of severe environments. |

| C-2000 | N06200 | An extremely versatile nickel alloy resistant to corrosion in all acids and chloride solutions, over wide temperature ranges. |

| 800 | N08800 | Nickel-iron-chromium alloys designed to resist oxidation and carburization at elevated temperatures. They are highly resistant to chloride stress corrosion cracking and to embrittlement from precipitation of sigma phase. |

| G-3 | N06985 | This alloy has good weldability and resistance to intergranular corrosion in the welded condition. |

| 904L | N08904 | This alloy is designed for a middle to high level of corrosion resistance. |

| 800H | N08810 | Nickel-iron-chromium alloys designed to resist oxidation and carburization at elevated temperatures. They are highly resistant to chloride stress corrosion cracking and to embrittlement from precipitation of sigma phase. |

| G-30 | N06030 | A high chromium nickel-base alloy which shows superior corrosion resistance over most other nickel and iron-base alloys in commercial phosphoric acids and complex environments containing highly oxidizing acids. |

| 800HT | N08811 | Nickel-iron-chromium alloys designed to resist oxidation and carburization at elevated temperatures. They are highly resistant to chloride stress corrosion cracking and to embrittlement from precipitation of sigma phase. |