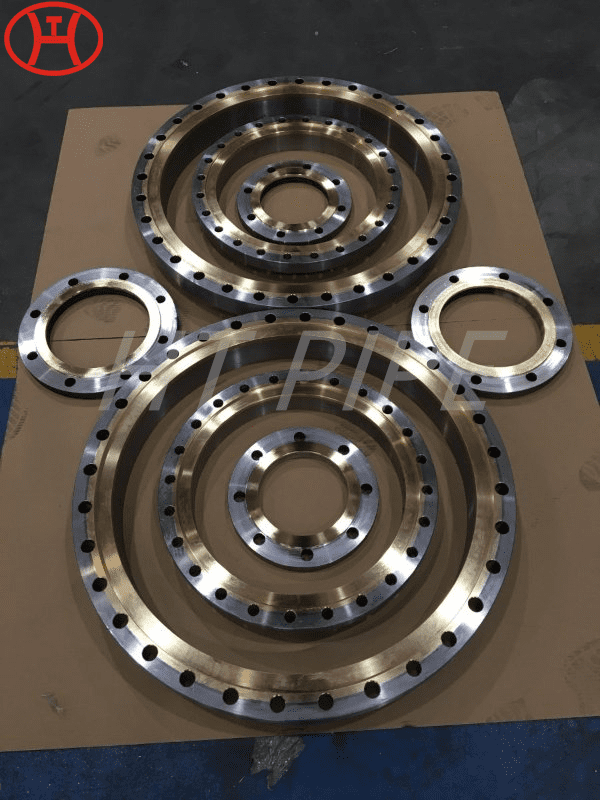

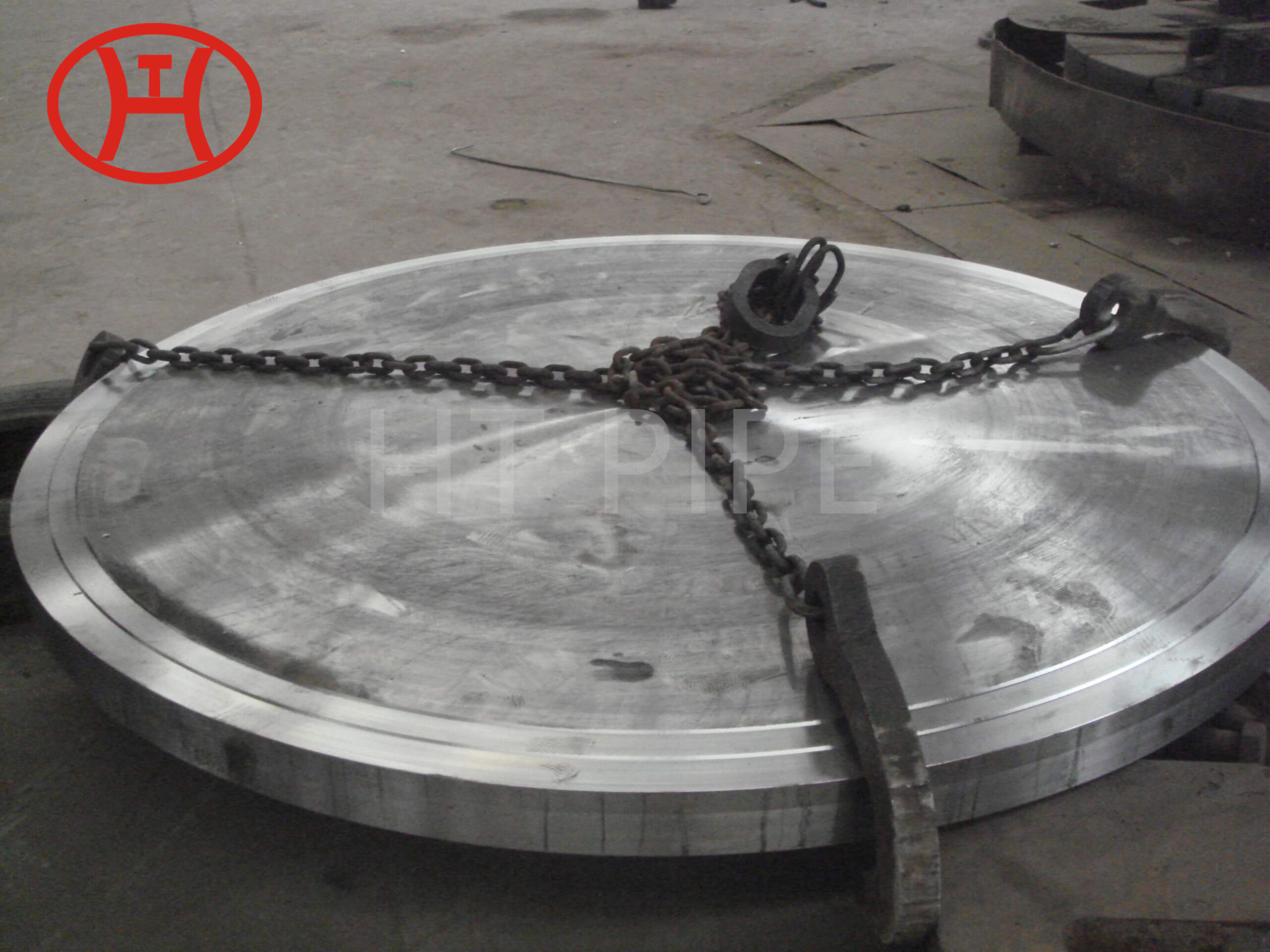

20 years experience machining 253MA flange for pipe

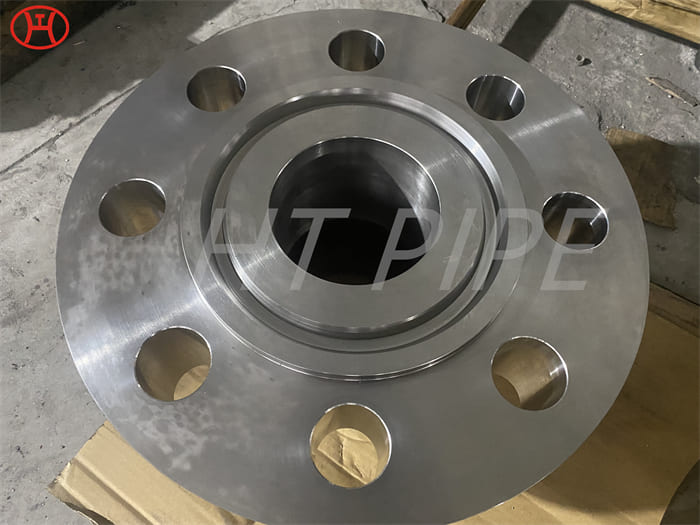

253MA steel pipe flanges are typically designed for low pressure, non-circulating industrial applications. These 253MA flanges are typically used in low pressure conditions.

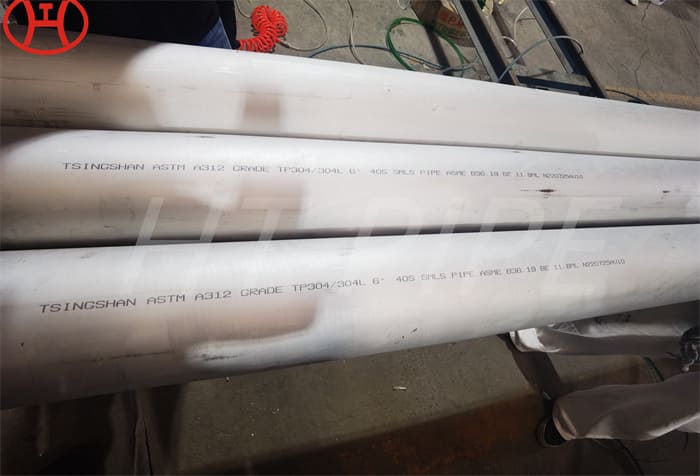

253MA is an austenitic chromium-nickel stainless steel with heat resistance and high strength. 253MA stainless steel contains nitrogen and reactive elements and is suitable for a variety of high temperature applications. The combination of rare earth metals and silicon provides excellent oxidation resistance up to 1150°C.

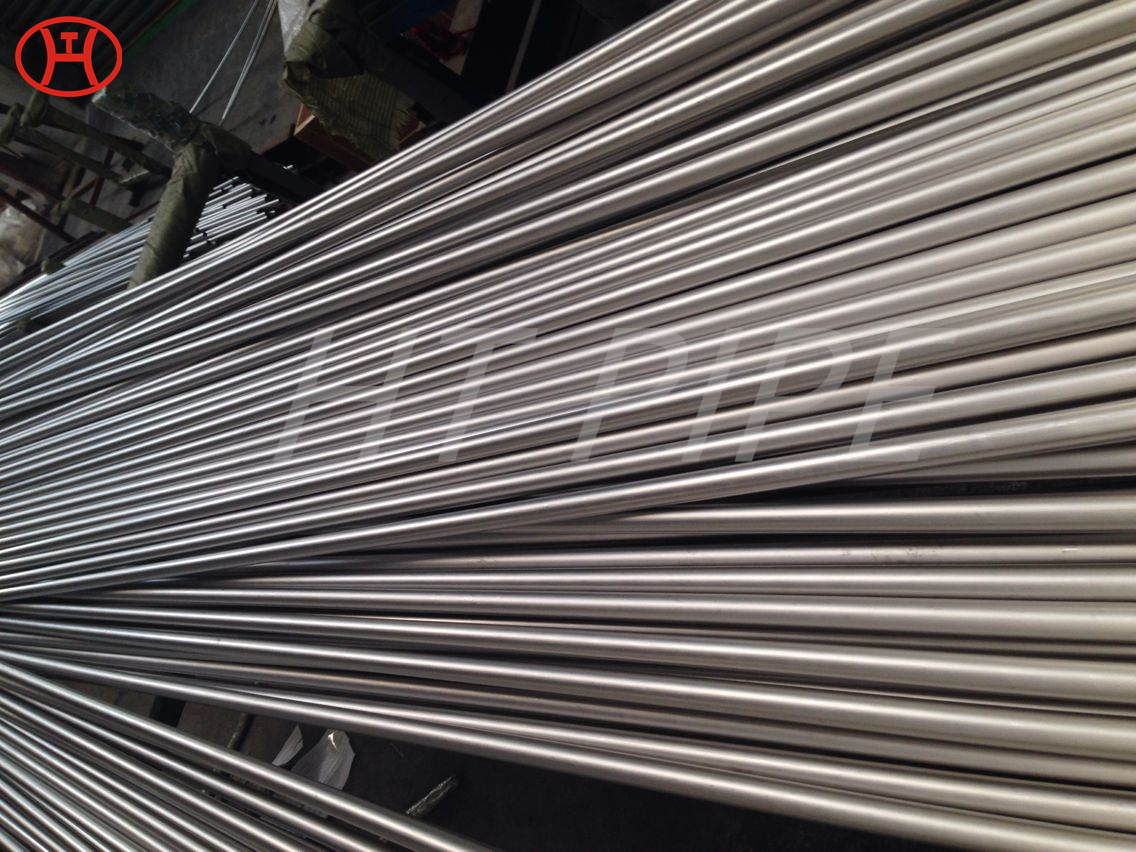

The chemical composition of stainless steel 235MA is nickel, copper, silicon, manganese, etc. The 235MA grade combines good high temperature performance. It’s easy to make. Stainless steel 235MA flanges have good oxidation resistance at high temperatures. The alloy’s low nickel content offers certain advantages in reducing the sulfidation atmosphere.

The mechanical strength of SS 253 MA flanges is divided into two categories, named within a typical range of hardness Rockwell B is Rb 90, its 2 inch elongation is 42% to 70%, its ultimate tensile strength is 90000 psi – 114000 psi and its 0.2% offset yield strength is 45000 psi – 69000 psi. However, the mechanical strength of a SS 253 MA flange within the specified minimum limits is its ultimate tensile strength of 87,000 psi, its 2″ elongation of 40%, its area reduction of 50%, and its 0.2% offset yield Strength is 45000 psi.