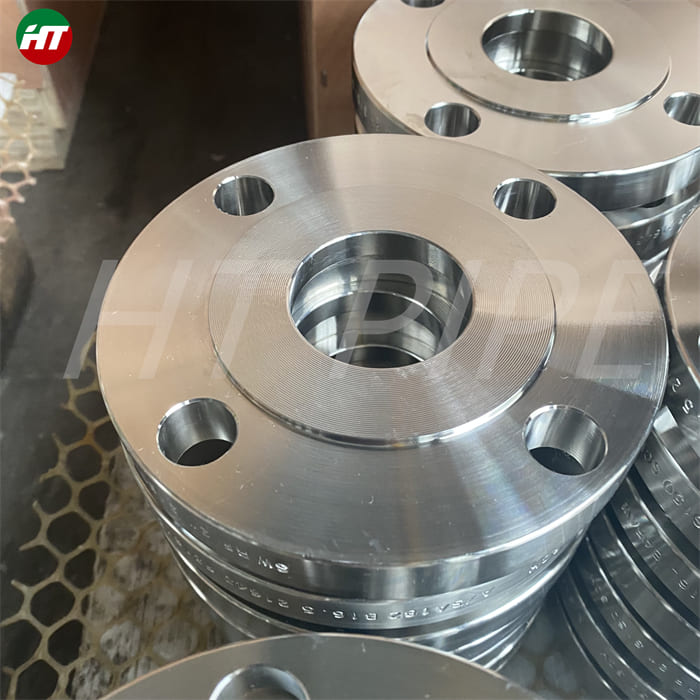

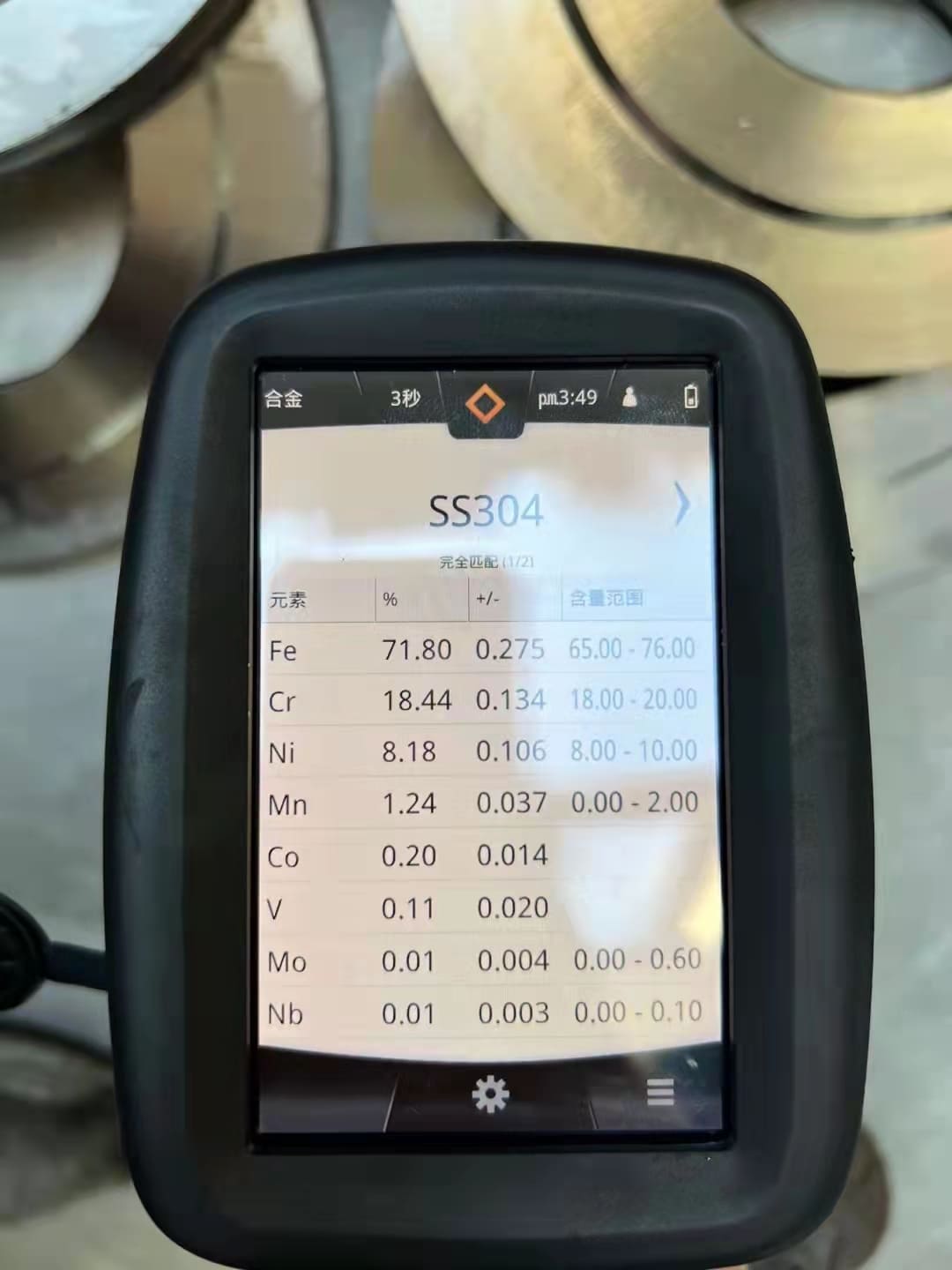

2022 china ss304 flange PMI test

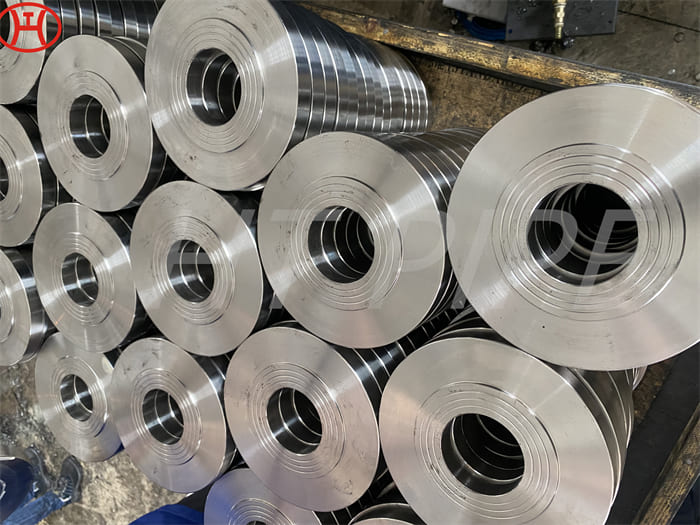

Stainless Steel 304 Flange is the parts which connects two pipe ends, flange connection is defined by the flange, gasket and bolt three are connected as a group of combined sealing structure of the detachable connection.

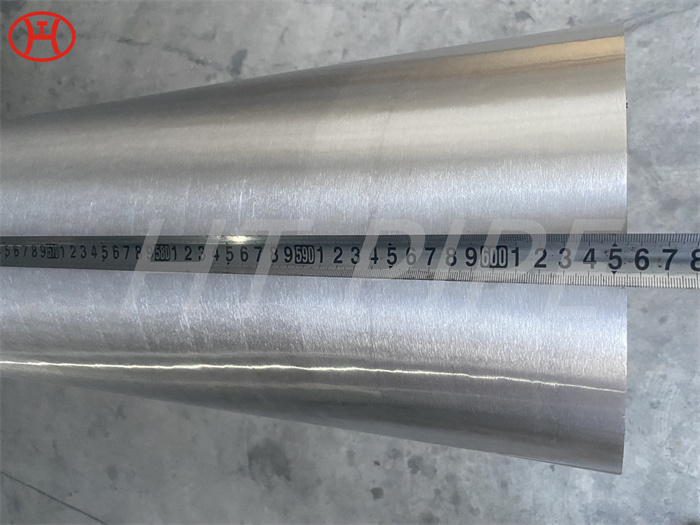

Stainless Steel 304 Flanges, SS F304 Flange, Stockist of Stainless Steel 304 Slip On Flanges, SS 304 Blind Flanges Dealer in China, SS UNS S30400 Pipe Flanges, Global Supplier of SS 304 Weld Neck Flange, ANSI B16.5 SS 304 Orifice Flanges, BS10 Table D, Table E, DIN Standard Flanges.

Stainless Steel 304 Flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. It also provides easy access for cleaning, inspection or modification. Flanges are usually welded or screwed. Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal.

The gasket is added between the Stainless steel 304 flangees and then fastened by bolts. Different pressure flange, thickness is different, and the bolts they use are different, when pump and valve connect with pipe, the parts of the equipment are also made of the corresponding Stainless steel 304 flange shape, also known as flange connection, usually closured bolted connection parts are also known as Stainless steel 304 flanges, such as the connection of ventilation pipe, this kind of parts can be called “flange type part”, but this connection is only part of a device, such as the connection between flange and water pump, it’s not inapposite to call water pump as flange type parts,but relative small valve,it can be called as flange type parts.

Grade 304 Stainless Steel is the standard “18/8” stainless; it is the most versatile and most widely used stainless steel, available in a wider range of products, forms and finishes than any other. It has excellent forming and welding characteristics. The balanced austenitic structure of Grade 304 enables it to be severely deep drawn without intermediate annealing, which has made this grade dominant in the manufacture of drawn stainless parts such as sinks, hollow-ware and saucepans. For these applications it is common to use special “304DDQ” (Deep Drawing Quality) variants.

Grade 304 Stainless Steel Flanges is readily available for applications in the industrial, architectural, and transportation fields. Grade 304 also has outstanding welding characteristics. Post-weld annealing is not required when welding thin sections.

They are easy to weld and provide a strong welded connection in gasoline and fresh water tanks. Butt weld flanges come in handy if temperature fluctuations are part of the production process. Our SS DIN 1.4301 Sliding Flanges are being shipped to African countries on a large scale. We also offer a variety of stainless steel ASTM A182 304 flanges such as SS 304 Slip Flanges, SS 304 Butt Weld Flanges, SS 304 Socket Weld Flanges, and SS 304 Blind Flanges. The high chromium content in the alloy provides the ASME B16.9 Sa 182 Gr F304 BLRF flange with resistance to oxidizing solutions such as up to 55% nitric acid by weight and temperatures up to 176°F. Flanges made of Alloy 304 are also resistant to moderately corrosive organic acids such as acetic acid.

HT PIPE is recognized as the prominent Manufacturer, Exporter and Supplier of a broad assortment of 304 Stainless Steel Flanges. The offered ASTM A182 F304 Flanges is designed with utmost precision in conformity with the international quality standards.

Chemical Composition of Grade F304 Stainless Steel Pipe Flanges

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 | – |

Mechanical Properties of ASTM A182 SS 304 Plate Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |