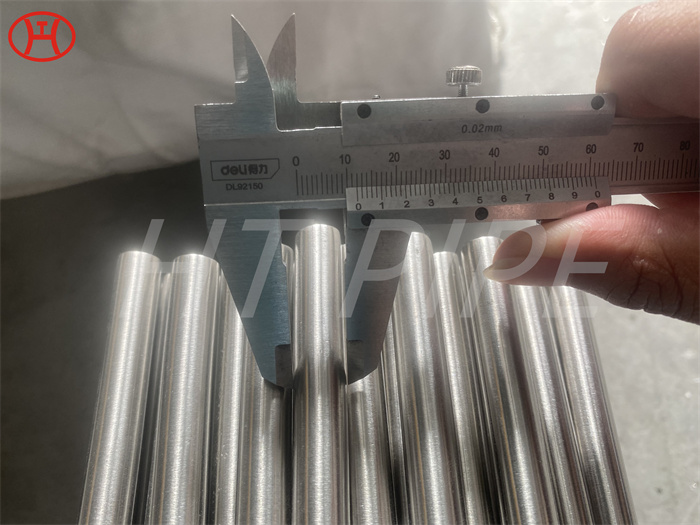

2205 duplex round bar ideally suited for high-pressure

Duplex steel UNS S32205 round bar has excellent corrosion resistance and resistance to localized corrosion such as intergranular corrosion, crevice corrosion and pitting corrosion.

Duplex steel UNS S32205 bars are used in a variety of applications such as chemical process vessels, piping and heat exchangers; pulp mill digesters, bleach scrubbers, chip pre-steam vessels; food processing equipment; oil field piping and heat exchangers; gas Desulfurization equipment. UNS S32205 or duplex alloy grade 2205 has a two-phase or duplex ferritic and austenitic microstructure. UNS S32205 F60 Round Bar Contains alloying elements such as 22% chromium, 3% molybdenum, 5 to 6% nickel alloyed stainless steel.

It combines higher resistance to stress corrosion cracking, pitting, crevice corrosion and high strength than other stainless grades. UNS S31803 grade duplex resistant to chloride environments and sulfide stress corrosion. Its yield strength is approximately twice that of standard austenitic stainless grades. Like other duplex stainless steel grades, it has good oxidation resistance at high temperatures, but is susceptible to embrittlement when exposed to above 300¡ãC, and is susceptible to embrittlement at 475¡ãC after only 2 hours of exposure. Embrittlement also occurs with prolonged exposure between 370-540¡ãC.