254 SMO pipe fabrication aggressive chloride-bearing environments

This grade has surpassed its original intent and overlapped into many industries proving useful owing to its high level of molybdenum amount other elements, which allows 31254 to be used successfully in various applications such as Flue gas desulfurization and Chemical environments.

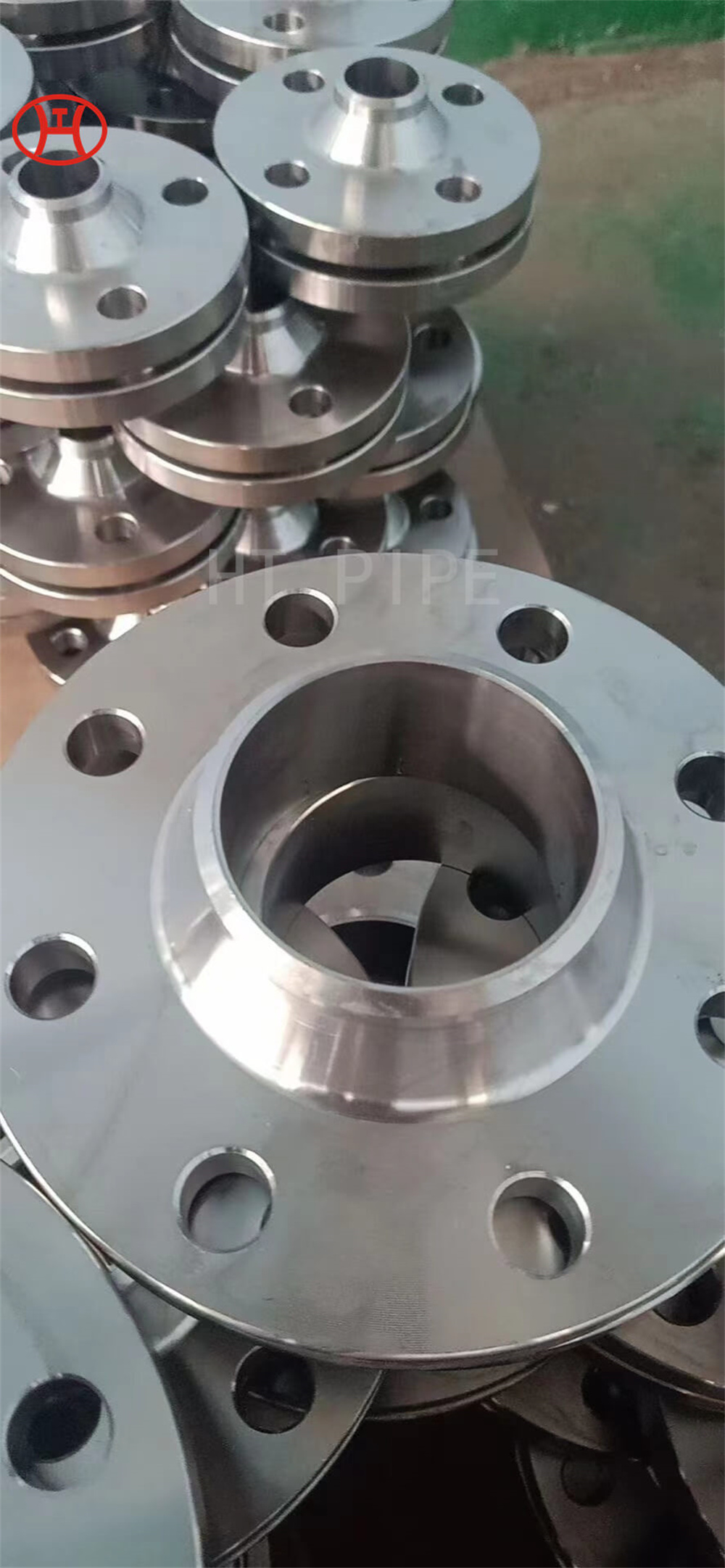

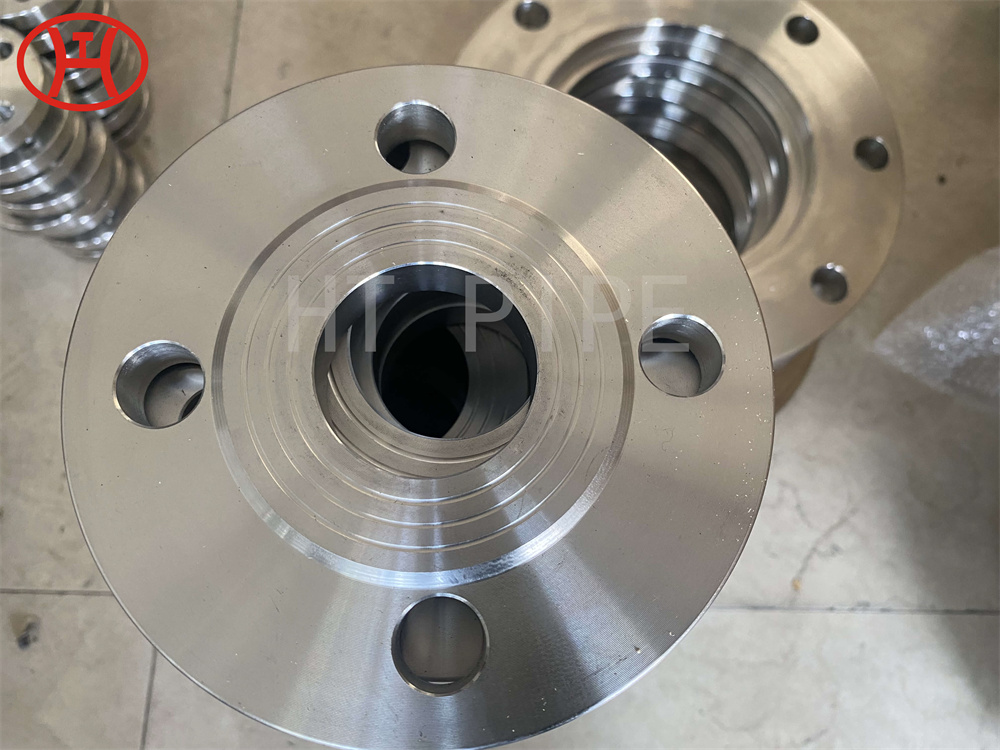

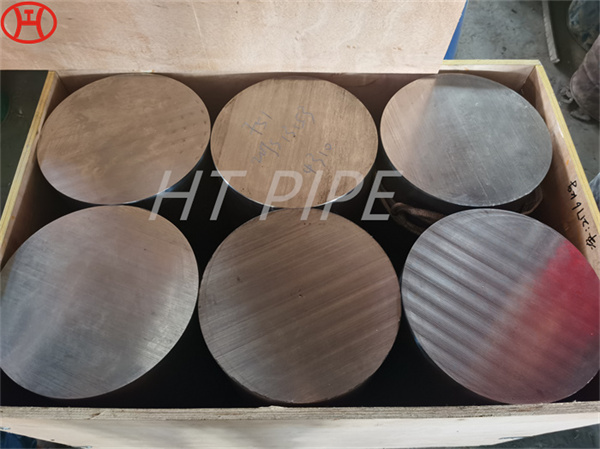

Alloy 254 SMO is much stronger than common austenitic grades, nearly twice as strong as 300 series stainless steel. It also features high ductility and impact strength. This is a high alloy material with a recommended forging temperature range of 2370/1920?F (1300/1050?C) followed by solution annealing at a minimum temperature of 2100?F (1150?C). 254 SMo / EN 1.4547 / UNS S31254 / 6Mo are generally used in pumps, valves, chokes, pipes/flanges and manifolds and have a high resistance to general corrosion.