Home » Materials » 254 SMO pipe fabrication impact toughness resistance to corrosion cracking

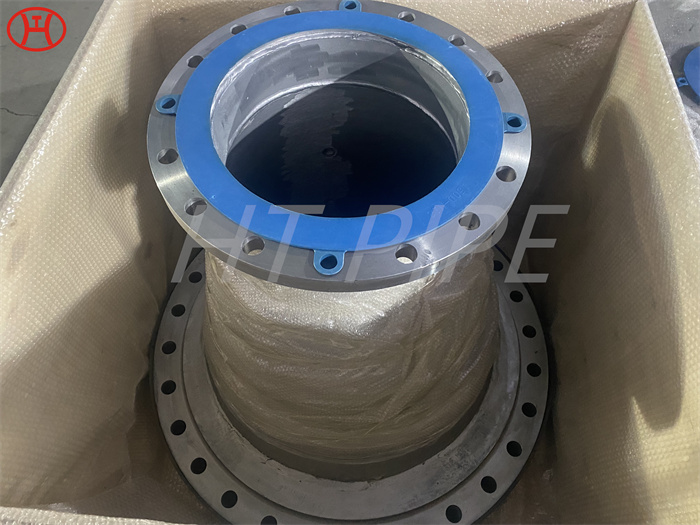

254 SMO pipe fabrication impact toughness resistance to corrosion cracking

For certain applications, grade 254 SMO has been reported to be a cost-effective substitute for high nickel and titanium alloys.

Contact US

Get Price

Share:

Previous:

316L prefab pipe more carbon

Content

Due to its high alloy content of chromium and molybdenum, it can withstand a wide range of acids. Resistance to pitting and crevice corrosion mainly depends on the content of chromium, molybdenum and nitrogen. Chemical analysis of the 254 SMO grade shows that both ferrite and austenite are formed when the weld cools and are resistant to hot cracking. The steel was developed for use in halide-containing environments such as seawater. Some common applications are offshore, marine environments and the chemical industry.

Inquiry

More Stainless steel