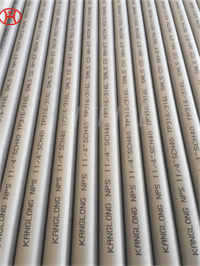

254 Smo Seamless Pipe Suppliers in China view 254 smo tubing price

Heat treatment does not affect 254 Smo Stainless Steel Pipe they can only be hardened via cold reduction. SMO 254 Erw Tubes have a great influencing potential and ductility at ambient and sub-zero temperatures.

UNS S31254 Welded Pipe Exporter, Suppliers of ASTM A409 SMO 254 Seamless Pipes, SMO 254 Bush Hex Pipe, SMO WERKSTOFF NR. 1.4547 Pipe Manufacturer in China.

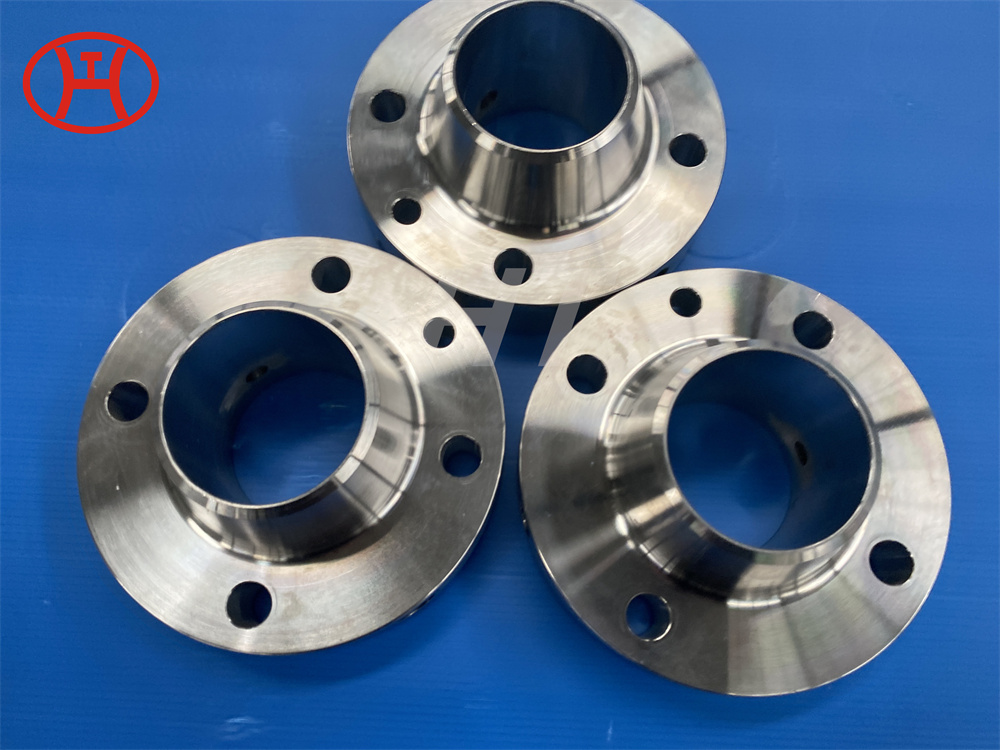

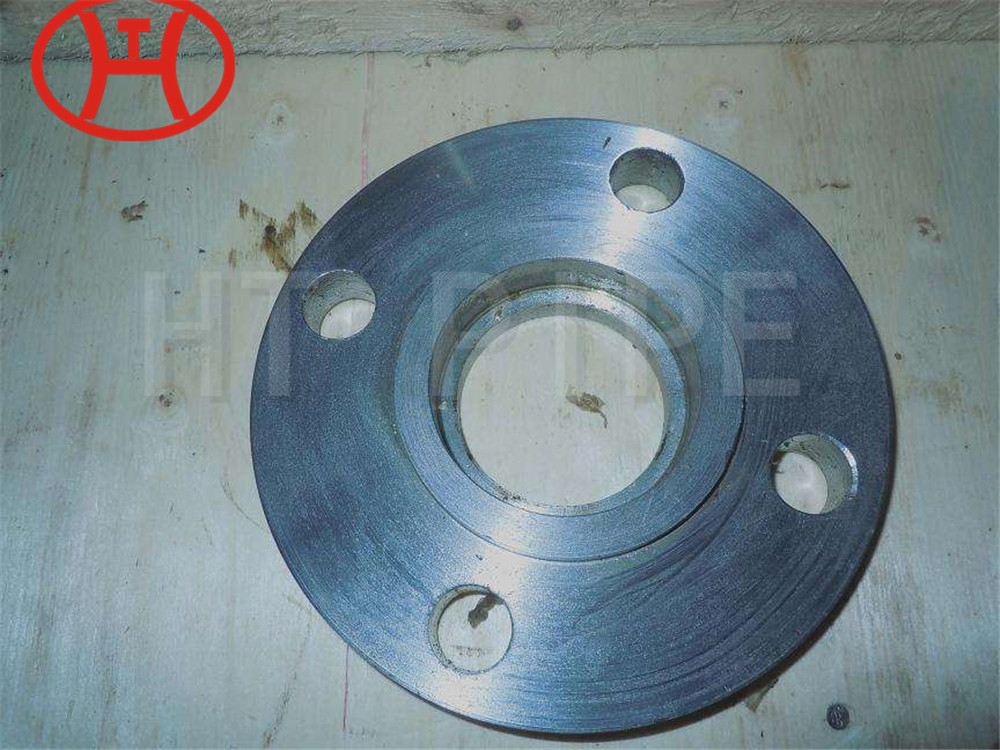

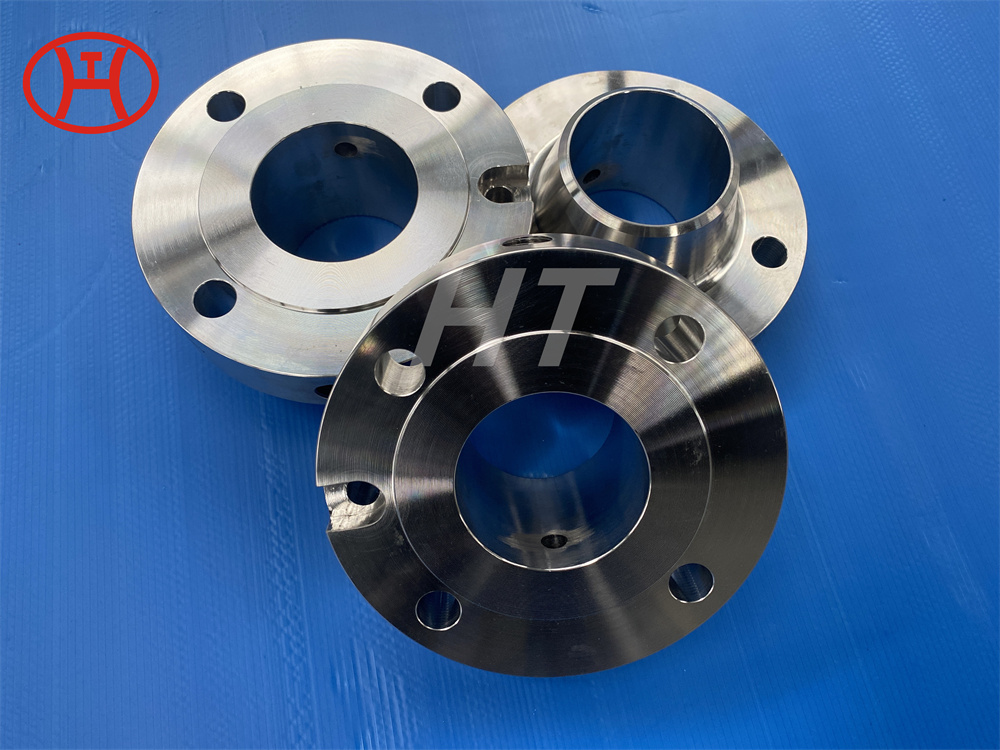

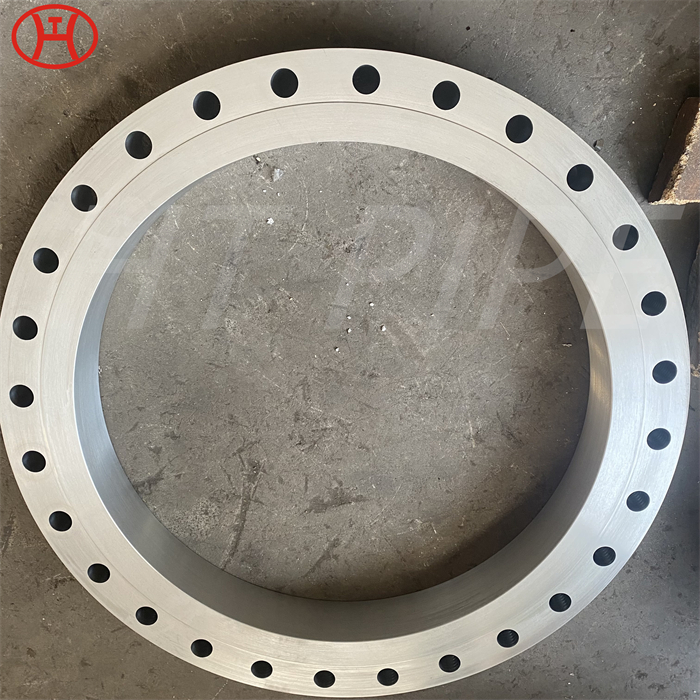

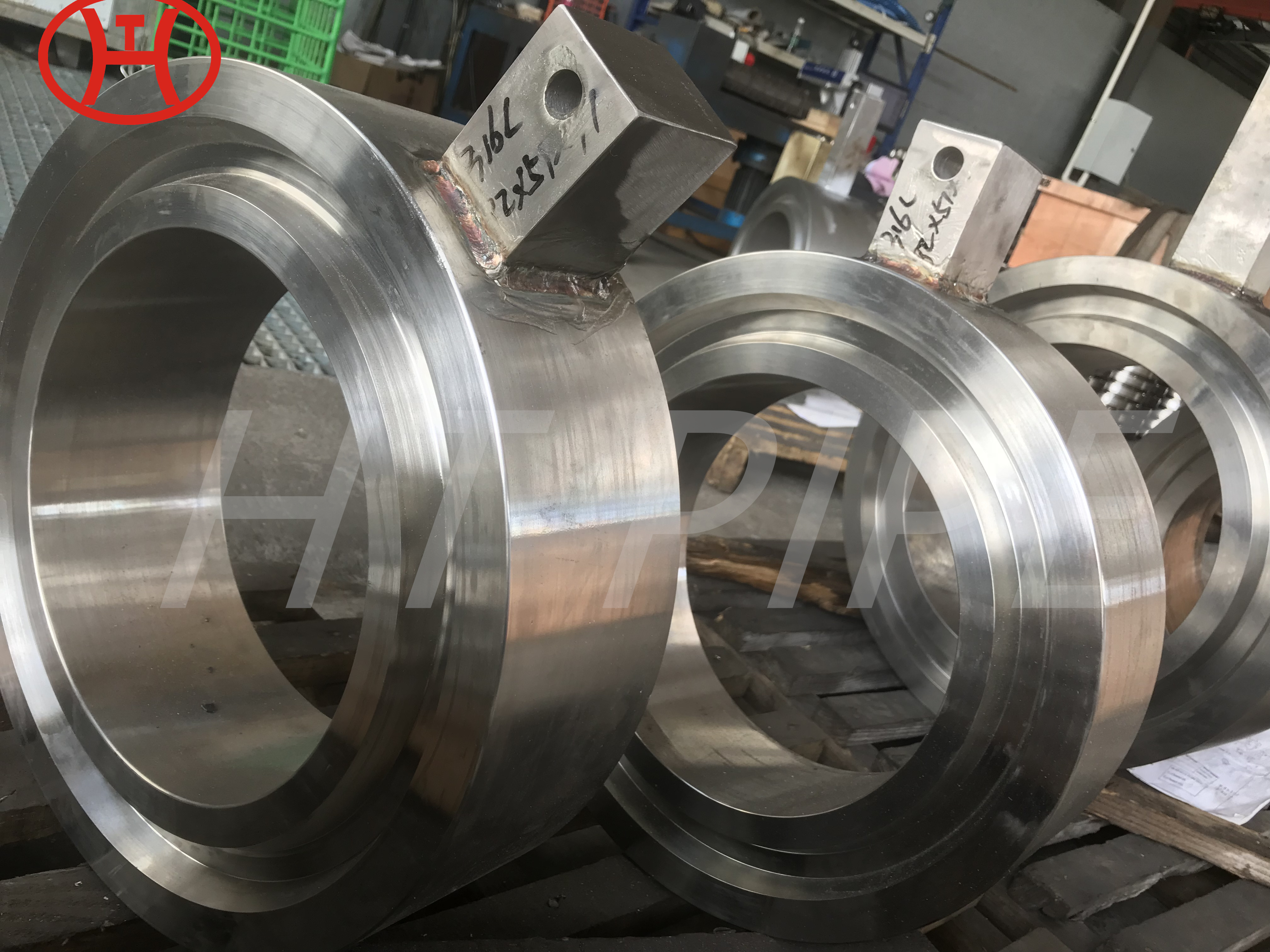

1.4547 Hollow Pipe produces a weld that has better corrosion resistant properties than its parent metal due to it being over alloyed. SMO 254 Pipe Manufacturers supply these pipes in various shapes and dimensions. Sch40 254 Smo Square Pipe and Alloy 254 Rectangle Pipe are a few examples. HT PIPE offers a wide array of 254 SMO Pipes, which is well ¨C tested on varied parameters thereby ensuring its high quality and durable standards. 254SMO 1.4547 is an austenitic stainless steel designed for maximum resistance to pitting and crevice corrosion.

With high levels of chromium, molybdenum, and nitrogen, 254SMO is especially suited for high chloride environments such as brackish water seawater pulp mill bleach plants and other high chloride process streams. SMO 254 Round Pipes (UNS S31254) is designed for maximum resistance to pitting and crevice corrosion. SMO 254 Seamless Pipes is developed for use in halide-containing environment such as seawater. ASTM A409 SMO 254 Seamless Pipe offers chloride resistance superior to that of Alloy 904L Alloy 20, Alloy 825 and Alloy G. 254SMO is compatible with the common austenitic stainless steels.

It is often used as a replacement in critical components of larger constructions where Type 316L or 317L has failed by pitting, crevice attack, or chloride stress corrosion cracking. In new construction, 254SMO has been found in many cases to be a technically adequate and much less costly substitute for nickelbased alloys and titanium. SMO 254 Welded Pipes is a very high end, molybdenum and nitrogen alloyed super austenitic stainless steel with low carbon content. UNS S31254 EFW Pipes is an austenitic stainless steel with high molybdenum content. SMO 254 ERW Pipes is often used in Flue ¨C gas cleaning, Desalination, Heat exchangers, and more.

| SMO 254 | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr |

| 17.5 – 18.5 |

0.02 max | 6 – 6.5 |

1 max | 0.8 max | – | 0.5 – 1 | 0.01 max | 0.03 max | 19.5 – 20.5 |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.0 g/cm3 | 1320-1390 ℃ | 300 | 650 | 35 % |