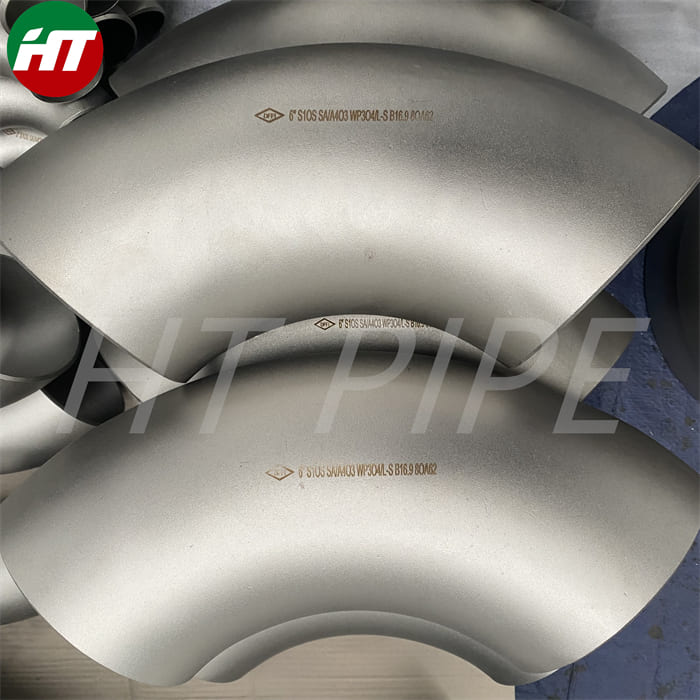

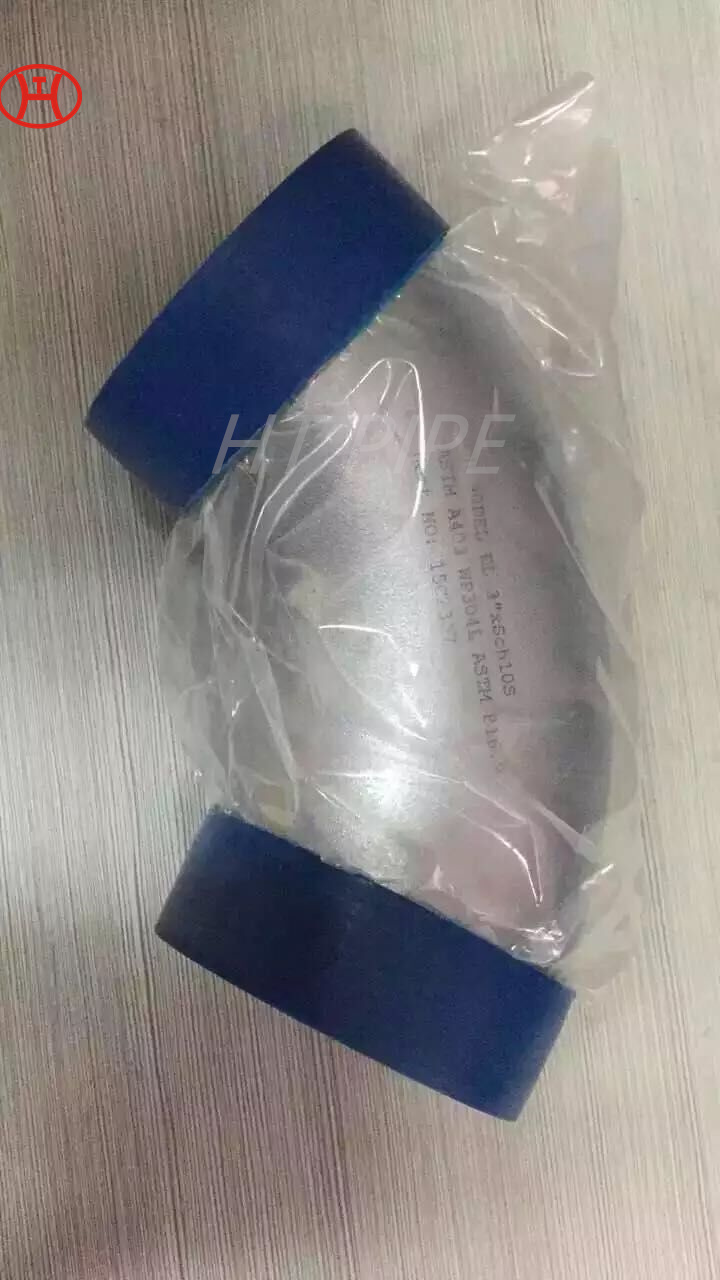

30 deg 304 elbow asme b16.9 bw 6 sch80 welded stainless steel pipe fitting elbows

The surfaces of these parts have a mottled appearance due to general corrosion. Additionally, they weaken the alloy and require frequent replacement to prevent catastrophic effects. Because the alloy has good resistance to general corrosion or uniform erosion, from a financial standpoint, the industry can use 304 stainless steel welded fittings without denting their pockets.

SS 304/304L Pipe Fittings Manufacturers, SS 304 Pipe Bends, Elbows, Flanges Manufacturer / Suppliers in China

Stainless Steel 304 Seamless Pipes, SS 304 Welded Pipe Manufacturers in China, with Elbows, Tee, Reducer, Stub Ends

ASTM A403, ASTM A182, ASTM A240 – SS 304 Pipe Fittings, SS 304 Flanges Manufacturers & Suppliers in China

Stainless steel 304 fittings are designed for pressure piping applications and can be used in a variety of forming or forging operations. Typically, these operations may be performed in combination with two or more of the following processes, namely hammering, bending, fusion welding, pressing, piercing, extrusion, upsetting, rolling, and machining.

SS 304 Fittings are used in piping systems to connect pipes and fittings together. 304 stainless steel pipe fittings come in different types and shapes for different uses and applications. ASTM A403 wp304 Butt Weld Fittings are made of 304 material grade stainless steel. ASTM A403 grade wp304 fittings are the most common fittings as most applications use 304 material grade pipe.

Class 304 is a common practice for 304l to obtain dual certification. Type 304 stainless steel is widely used, widely used in series, and has excellent forming and welding characteristics. ASTM A304 wp304 butt welded pipe fittings are used in a variety of industries and tend to have good properties and provide high tensile strength, good dimensional accuracy, weldability, flexibility, durability and longevity.

| Product | Stainless Steel 304 Pipes & Fittings |

| Equivalents | WNR. 1.4301, UNS S30400, AISI 304, AISI 304L, 1.4306, UNS S30403 |

| Type | Seamless, Welded, Forged |

| Size | 1/2″ to 48″, Thickness: SCH 5S, 10S, 40S (STD), 80S (XS), 160, XXS |

| Specification | ASTM, ASME, DIN |

| Finish | Annealed & Pickled, 2B, No.4, Mirror, Polish |

| Packing | Bundled Packing |

| Services | Cutting, Beveling, Threading, Polishing |

Mechanical Properties

| Elongation A50 mm | 45 Min % |

| Proof Stress (MPa) | 230 Min |

| Tensile Strength (MPa) | 540 – 750 |

Physical Properties

| Property | Value |

| Thermal Expansion | 17.2 x 10-6/K |

| Density | 8.00 g/cm3 |

| Melting Point | 1450 °C |

| Modulus of Elasticity | 193 GPa |

| Electrical Resistivity | 0.72 x 10-6 Ω.m |

| Thermal Conductivity | 16.2 W/m.K |