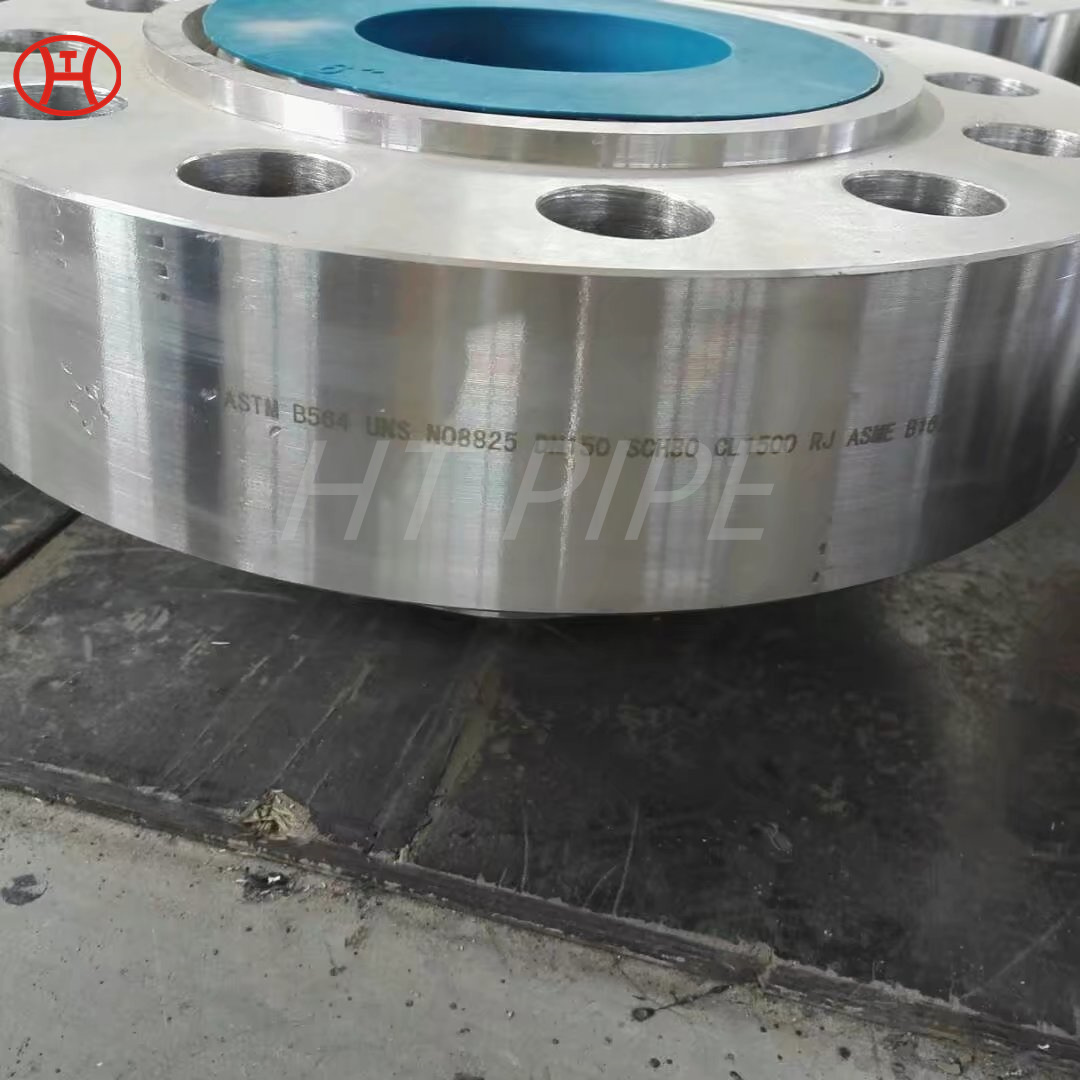

300mm diameter steel pipe alloy 825 uns n08825 tubing

The seamless nature results in a very uniform surface, which results in a uniform wall thickness along the length of the pipe. There are alloy nickel tubes and pure alloy tubes. Pure nickel pipe is actually commercially pure and contains about 99% nickel in its composition. Nickel welded pipe is ideal for welding needs. Nickel is inherently very corrosion resistant and lightweight. These attributes of elements are used in various applications.

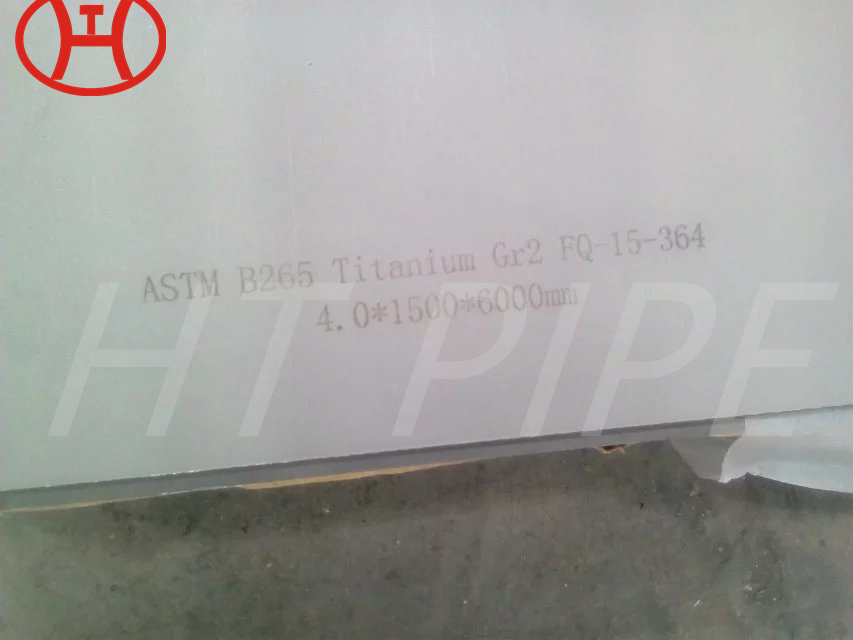

ASTM B423 UNS N08825 Alloy 825 Seamless Pipe, Get a Quote from 825 Incoloy Seamless Pipe, Incoloy WERKSTOFF NR. 2.4858 Pipe dealers in China

Alloy 825 is a nickel-chromium-iron solid solution strengthened alloy with a nominal chemical composition of 42% nickel, 21% chromium, and 22% iron, plus additions of molybdenum, titanium, and copper. It is commonly referred to by the tradename Incoloy® 825 and the universal designation UNS N08825.

Incoloy 825 alloy pipes are built from basic elements like iron, nickel, and chromium, which provide the basic resistance to rusting and pitting in normal temperatures. This alloy has some added elements in small portions like molybdenum, titanium, and copper which adds more substance to the product and increases its workability even in marine conditions. These chemical properties help the alloy to withstand the underwater environment and prevent it from Intergranular corrosion, crevice corrosion, pitting, stress corrosion cracking, and other corrosives.

Alloy 825 can be provided in the annealed condition or strengthened through the pilger process. Alloy 825 maintains useful mechanical properties up to about 1000°F (538°C) and good toughness down to cryogenic temperatures.

Chemical Material Composition of Alloy 825 Pipe

| Grade | C | Mn | Si | Fe | S | Cr | Cu | Ti | |

| 825 | min. | – | – | – | 22.0 | – | 19.5 | 1.5 | 0.6 |

| max. | 0.05 | 1.0 | 0.5 | – | 0.015 | 23.5 | 3.0 | 1.2 | |

Mechanical Properties of Inconel 825 Seamless Pipes

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 825 | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa –220 | 30 | – | – |