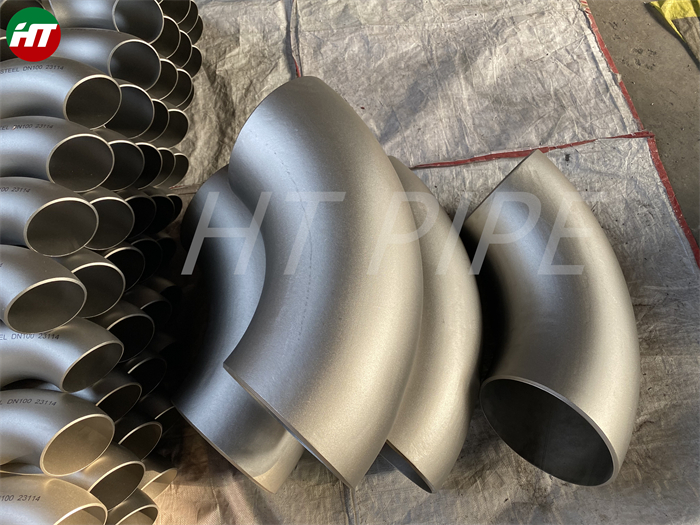

304 304L 316 316L 310 310S 347 347H elbows stainless steel pipe fittings

UNS S31603 Elbow also has excellent resistance to pitting corrosion and soaring tensile strength. They are machined to have tough and strong chip characteristics. SS 316L 45 Degree Elbow is also considered to be more resistant to general corrosion and pitting than normal Nichrome.

SS 304/304L Forged Pipe Fittings Manufacturers & Suppliers – Elbows, Couplings, Street Elbows, Inserts, Caps, Tees, Unions and Crosses

The SS 304 Elbow is one of the key components in the pressure piping system. It basically helps to change the direction of flow in the pipe run. These ASTM A403 Gr WP304 Buttweld Fittings help to connect two pipes with the same or different nominal diameters so as to change the fluid direction by 45 or 90 degrees.

304 stainless steel elbows are designed to withstand harsh corrosive environments. 304 elbows are used to help change the direction of the raceway. At the same time, we manufacture SA403 WP 304 short radius elbows and long radius elbows which are very strong with a minimum yield strength of 205MPa and a minimum tensile strength of 515MPa. These work well in high temperature environments up to 870 degrees Celsius. We are one of the leading stockists and manufacturers of Werkstoff No. 1.4301 180 Degree Elbow, which is available in various sizes depending on the type and thickness of specific requirements.

We are a specialized manufacturer of welded and seamless SS 304 pipe fittings for low or high temperatures, and medium or high pressures. HT PIPE is a largest supplier of ss 304 forged pipe fittings in China. We are offering excellent products and sincere service, and welcome all our customers.

All pipes supplied by HT PIPE are tested according to requirements of the appropriate standards. In all cases the tube leaking test is performed, and supplied with Test Certificates at per EN 10204 3.1 or NABL approved lab test reports. We focus on each and every customer with a personal touch, making us one of the top supplier of stainless steel pipes & tubes and a reliable business partner for all industrial buyers.

| UNS Designation & International Equivalent for SS 304 Forged Pipe Fittings | ||||||||

| Type | UNS | JIS | EN/DIN | EN/BS | EN/NF | ISO | GB | GOST |

| 304 | S30400 | SUS304 | X5CrNi18-10 | 304S31 | Z7CN18.09 | 11 | 0Cr18Ni9 | 08KH18H10 |

| 304L | S30403 | SUS304L | X2CrNi19-11 | 304S11 | X2CrNi19-11 | 10 | 00Cr19Ni11 | 03KH18H11 |

304/304L/304H Stainless Steel Forged Pipe Fittings Chemical Composition

| Chemical Composition % | ||||||||

| C | Mn | Si | P | S | Cr | Ni | Fe | |

| 304 | 0.08 max. | 2.00 max. | 1.00 max. | 0.045 max. | 0.03 max. | 18.0 – 20.0 | 8.0 – 10.5 | Balance |

| 304L | 0.03 max. | 2.00 max. | 1.00 max. | 0.045 max. | 0.03 max. | 18.0 – 20.0 | 8.0 – 12.0 | Balance |

| 304H | 0.04-0.10 | 2.00 max. | 1.00 max. | 0.045 max. | 0.03 max. | 18.0 – 20.0 | 8.0 – 12.0 | Balance |

304/304L/304H Stainless Steel Forged Pipe Fittings Mechanical Properties

| 304 | 304L | 304H | |

| Density | 8 | 8 | 8 |

| Melting Range,℃ | 1400 ℃ | 1400 ℃ | 1400 ℃ |

| Elongation % | 40 | 40 | 40 |

| Tensile Strength (Mpa) | 515 | 485 | 515 |

| Yield Strength (Mpa) | 205 | 170 | 205 |

| Hardness (Brinell) | 201 | 201 | 201 |