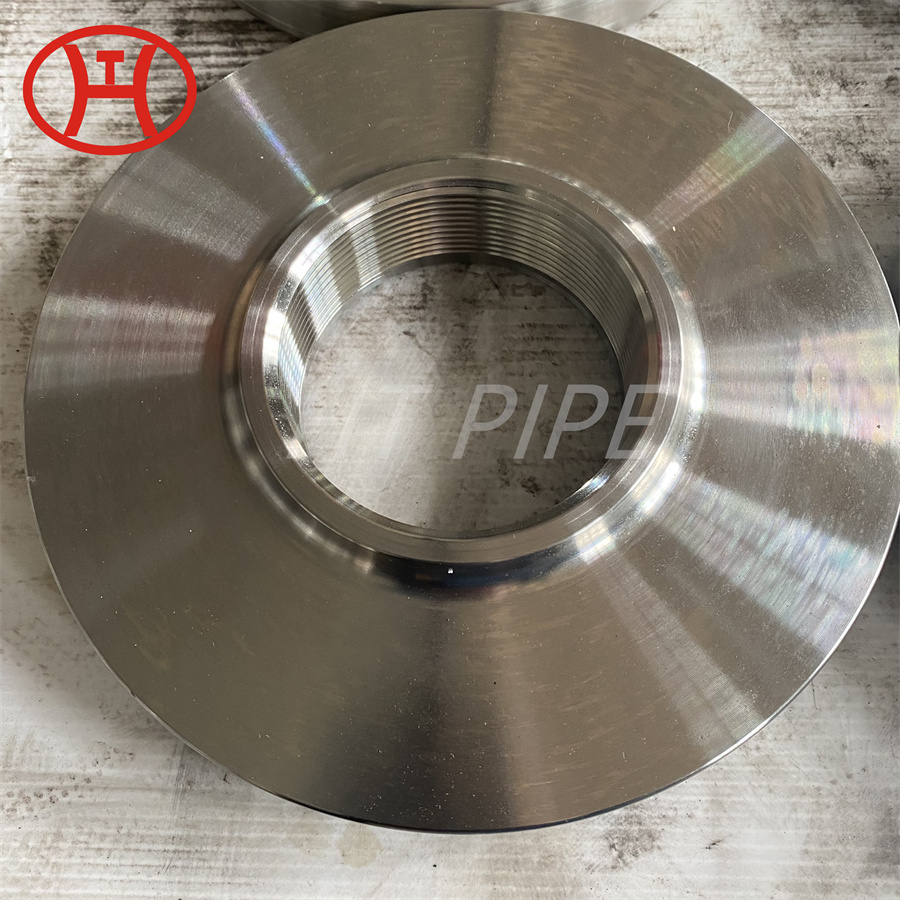

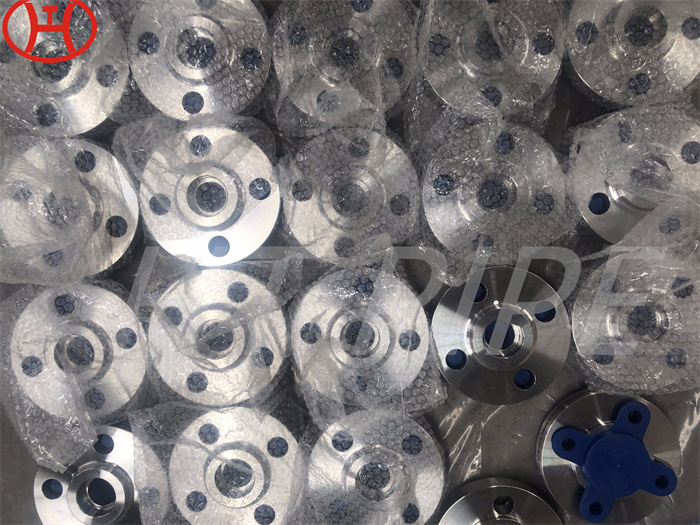

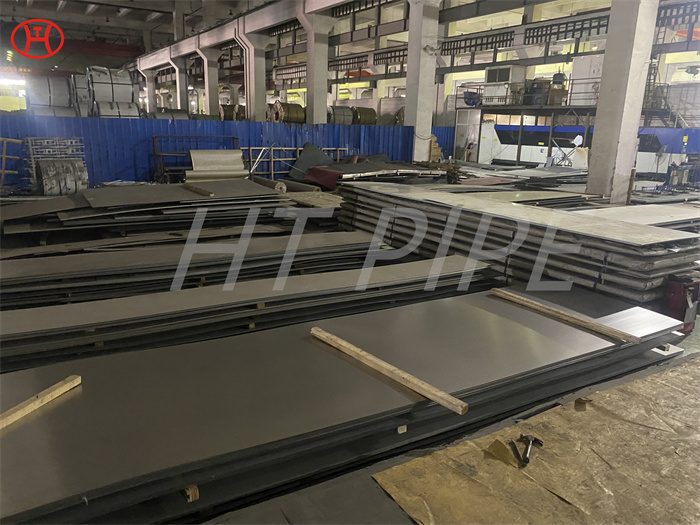

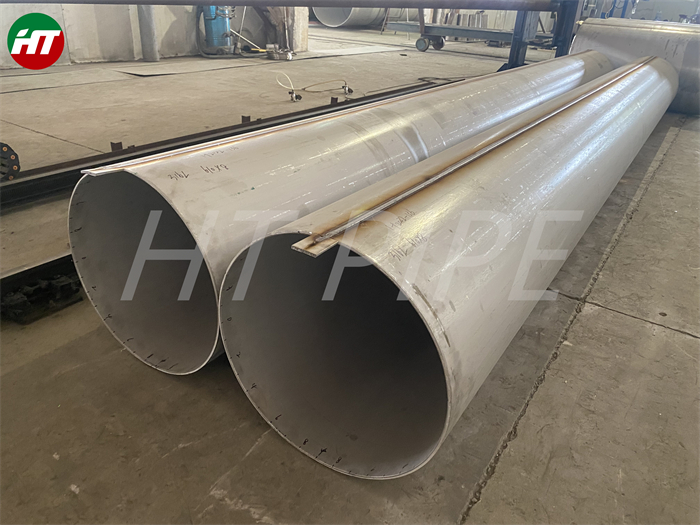

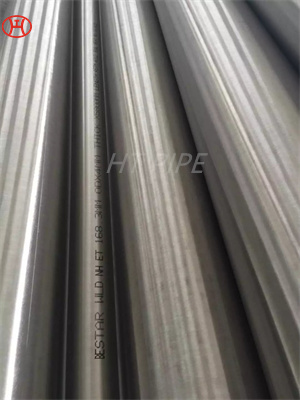

304 309s 310s 316l 316 stainless steel pipe/tube

Austenitic stainless steels of 304 and 304L are the most versatile and widely used stainless steels. They exhibit excellent corrosion resistance in a wide range of corrosive environments. Grade 304 and 304L stainless steel pipes exhibit good machinability and excellent weldability with or without filler metal additions.

Production standard of 304/310s/316/316l pipe

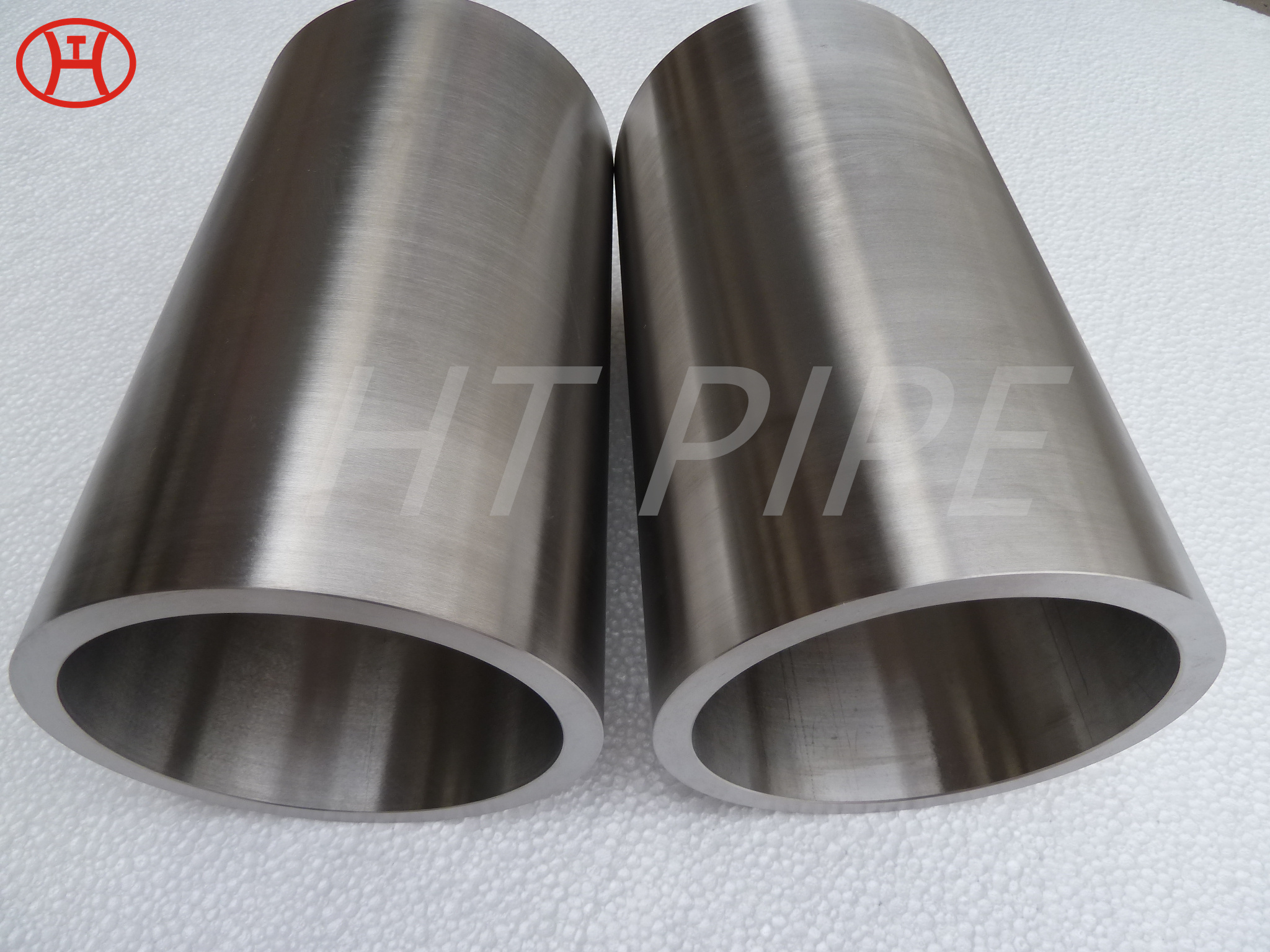

Type “Seamless Pipe

Seamless Tube

Welded Pipe

Welded Tube

SAW LSAW ERW EFW

Beveled End, Plain End”

Size “OD: 1/2″” ~48″”

Thickness: SCH5~SCHXXS

Length :As per your requirement.”

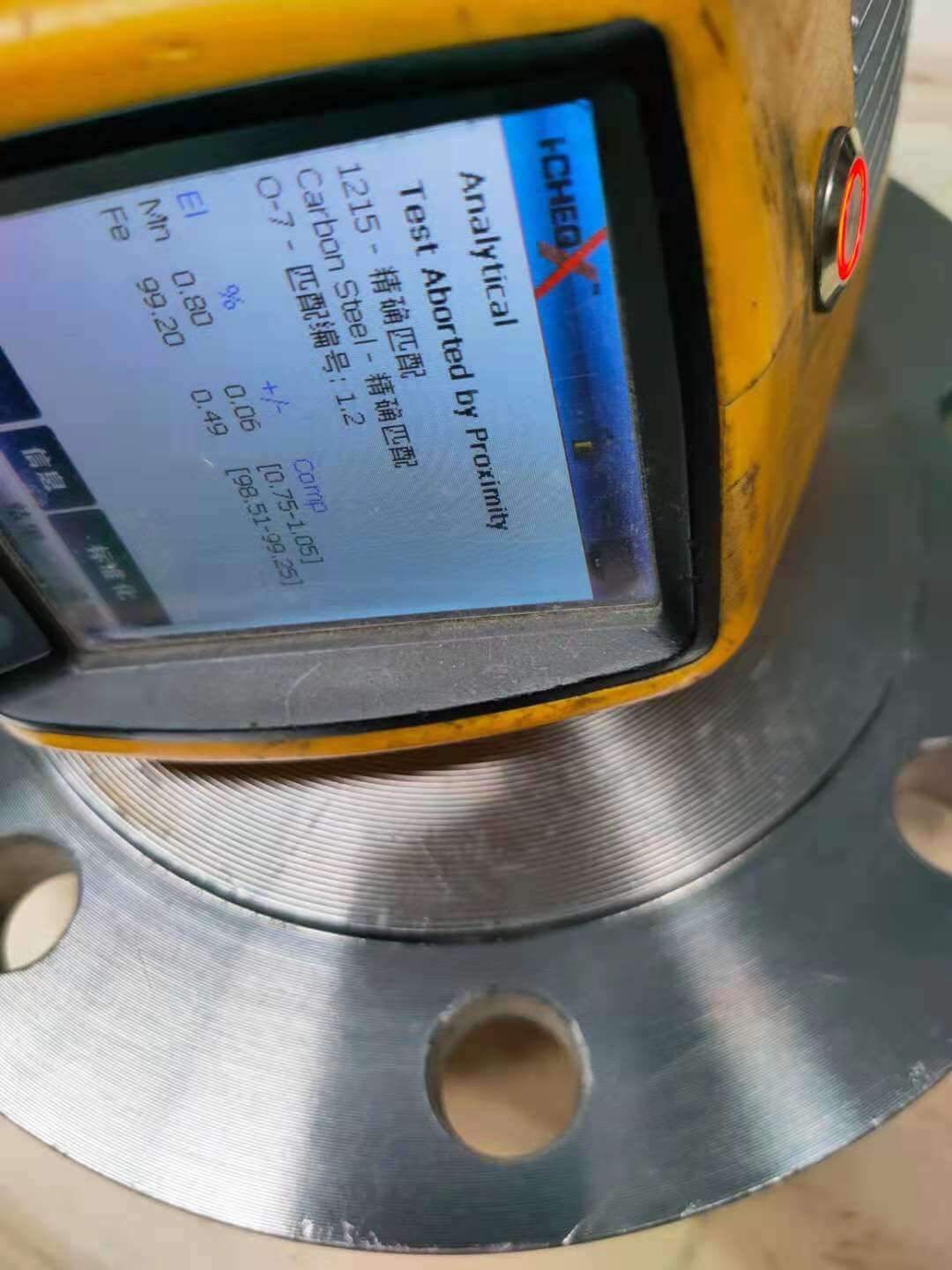

Material: ASTM A312 TP304,TP304L,TP316,TP316L,316Ti TP317,TP317L,TP321,TP310S,TP347,S31254,NO8367,NO8926,NO8904

ASTM A213 TP304,TP304L,TP316,TP316L,316Ti TP317,TP317L,TP321,TP310S,TP347,S31254,NO8367,NO8926,NO8904

ASTM A269 TP304,TP304L,TP316,TP316L,TP317,TP317L,TP321,TP347,S31254,NO8367,NO8926

ASTM B676 N08367

ASTM B677 UNS N08925, UNS N08957

Product Description of 304/310s/316/316l pipe

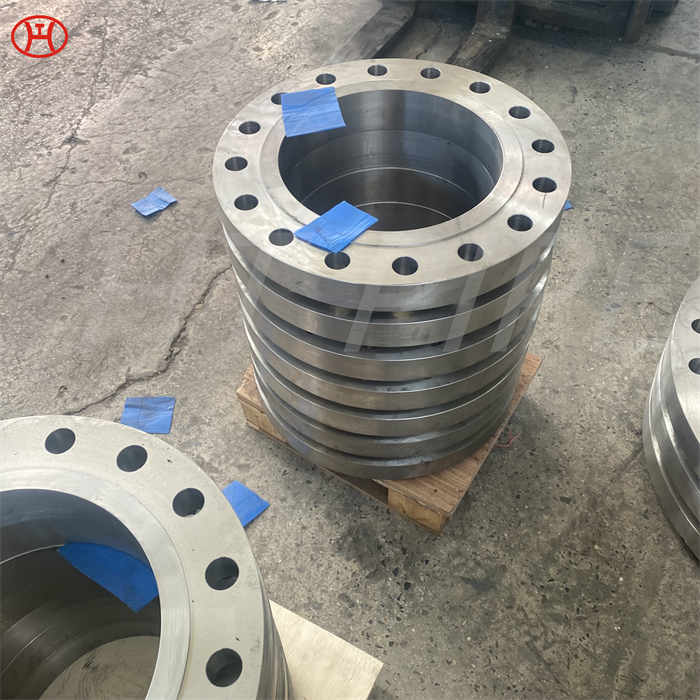

300 series of stainless steel are used widely, most of them have a strength of corrosion resistance, heat resistance and a good chemical performance. Specification Grade 301 , 304 , 304L , 316 , 316L , 309 S, 310 , and 321. Stainless steel is durable, resists corrosion from caustic chemicals, corrosive fluids, oils, and gases, and withstands pressure and high temperatures. Because stainless steel is also low-maintenance, oxidation resistant, and doesn’t affect other metals it comes in contact with, it is frequently used in a large array of applications, especially in piping, tubing, and fittings manufacturing.

A seamless pipe is a pipe that does not contain any seams or weld joints. It’s capable of standing up to intense levels of pressure and also temperatures thanks to the metal itself. It’s used in a wide variety of different oil and gas applications, but they are also used in mechanical and engineering industries too. Welded pipes can be used in virtually every industry thanks to its flexibility. However, they fare better in corrosion resistance as opposed to withstanding pressure.