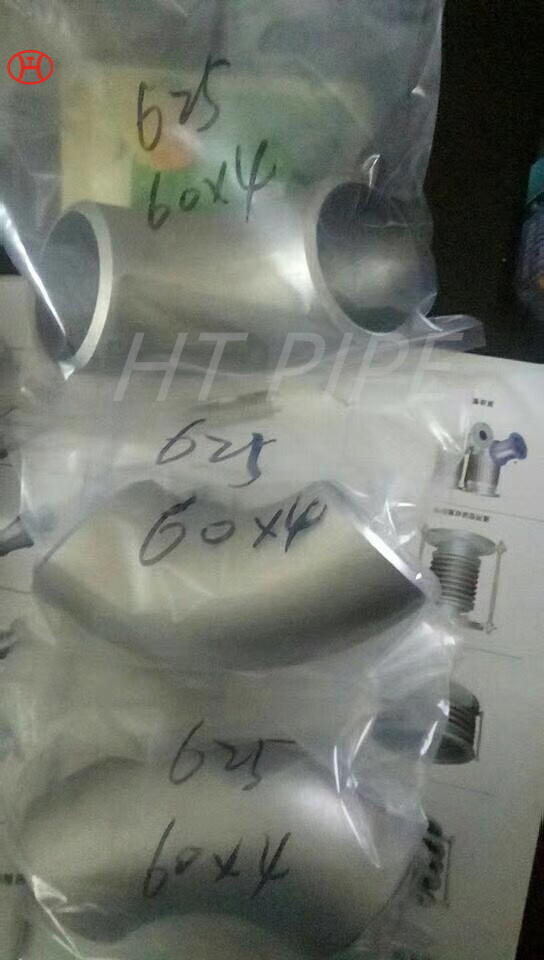

304 stainless steel elbow pipe fitting connector S30400 90 deg elbows

The 304 elbow is a stainless steel threaded pipe fitting that changes the direction of the pipeline in the pipeline system. According to the angle, there are 45 ¡ã and 90 ¡ã. In addition, according to engineering needs, it also includes other abnormal angles such as 60 ¡ã. The material of our threaded elbows is 304 stainless steel.

304 Pipe Fittings Manufacturer in India. Leading Supplier of 304 Buttweld Pipe Fittings with Fast Delivery and Best Quality. Our 304 Pipe Fittings is Exported Worldwide including Elbow, Tee, Reducer, Bend, Cap, Nipple, Cross etc.

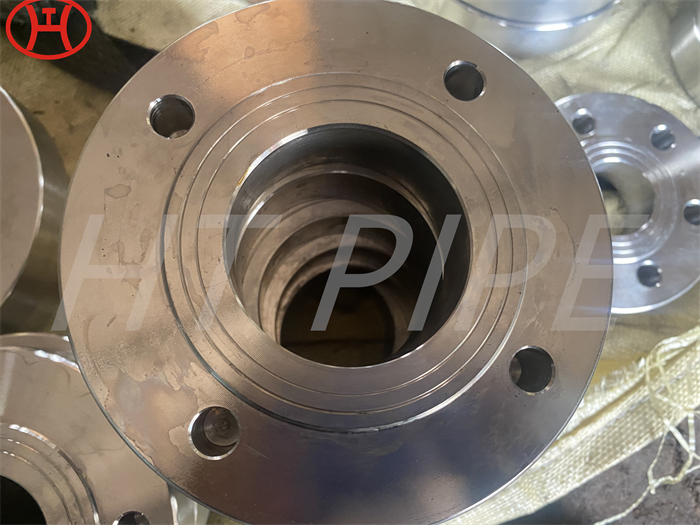

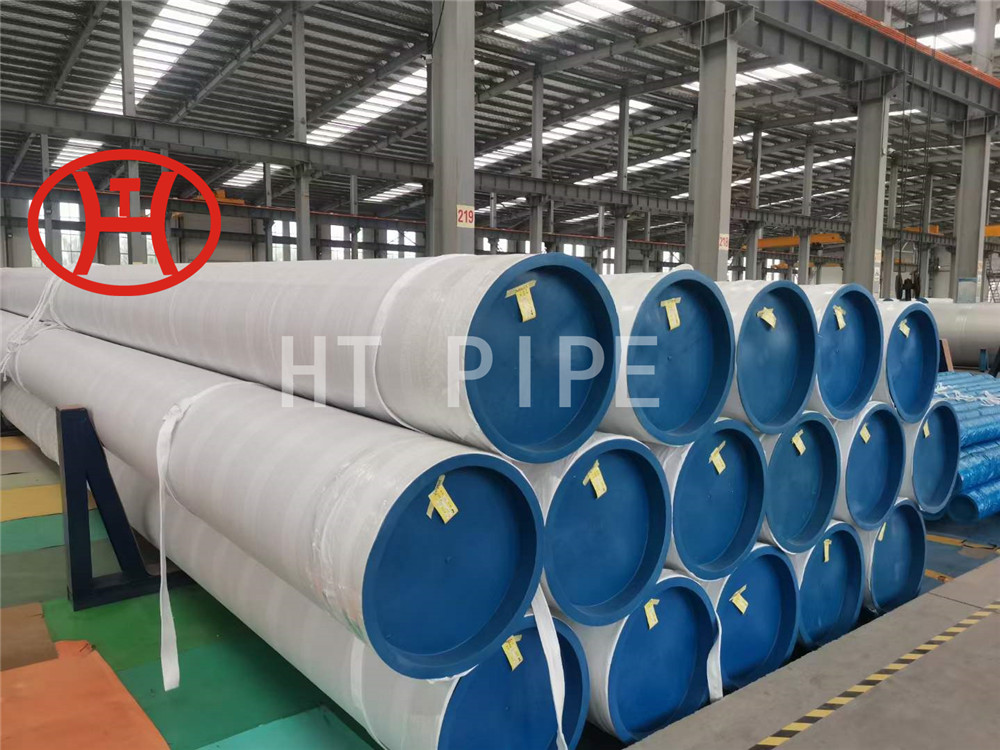

304 covers the standard for wrought austenitic stainless steel fittings for pressure piping applications. The material for stainless steel tube elbows shall consist of forgings, bars, plates, or seamless or welded tubular products. Forging or shaping operations shall be performed by hammering, pressing, piercing, extruding, upsetting, rolling, bending, fusion welding, machining, or by a combination of two or more of these operations.

The 304 Elbow is a stainless steel pipe fitting that has found its way into many industrial and commercial applications over the years. It is made from grade 304 stainless steel, which provides an excellent corrosion resistance to most environments. The 304 elbow has become increasingly popular due to its robustness, low cost, and easy installation.

When considering using a 304 elbow for your project, it’s important to understand what this type of pipe fitting offers in terms of strength and performance. Grade 304 stainless steel contains 18% chromium and 8% nickel alloys which gives it exceptional durability, making it ideal for use in situations where regular wear or pressure is expected. This combination also enables the material to resist environmental impacts including rusting when installed correctly with appropriate insulation or sealants applied.

304 Pipe Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 304 | min. max. | – 0.08 | – 2.0 | – 0.75 | – 0.045 | – 0.030 | 18.0 20.0 | – | 8.0 10.5 | – 0.10 |

| 304L | min. max. | – 0.030 | – 2.0 | – 0.75 | – 0.045 | – 0.030 | 18.0 20.0 | – | 8.0 12.0 | – 0.10 |

| 304H | min. max. | 0.04 0.10 | – 2.0 | – 0.75 | -0.045 | – 0.030 | 18.0 20.0 | – | 8.0 10.5 | – |

304 Pipe Fittings Mechanical and Physical Properties

Typical Values at 68°F (20°C)

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 304 | 515 | 205 | 40 | 92 | 201 |

| 304L | 485 | 170 | 40 | 92 | 201 |

| 304H | 515 | 205 | 40 | 92 | 201 |

| 304H also has a requirement for a grain size of ASTM No 7 or coarser. | |||||