304 316l stainless steel pipe fitting welded elbows

All stainless steel components meet the most stringent requirements for surface quality, microbial and corrosion resistance, high cleanability, material strength, uniform thickness, and crevice-free welding. This ensures uptime, safety, reliability and efficiency for duties across the dairy, food, beverage, home-personal care, and biotech and pharmaceutical industries.

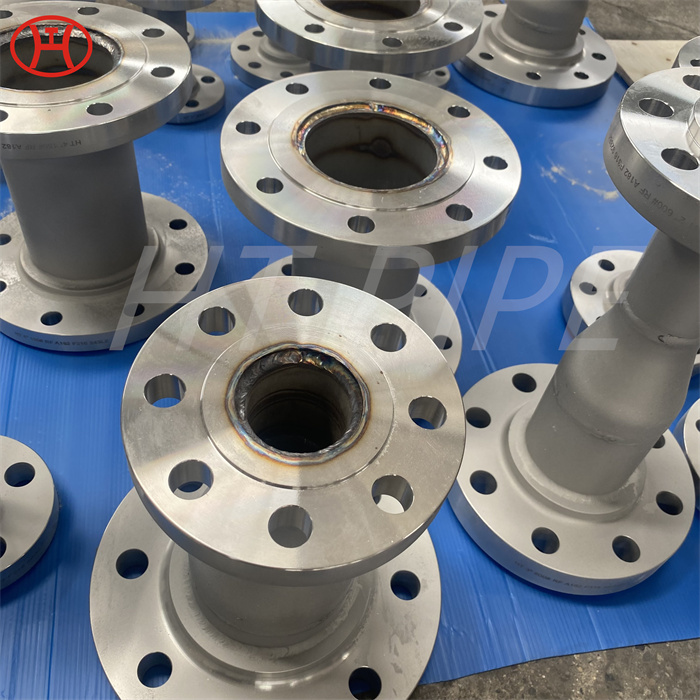

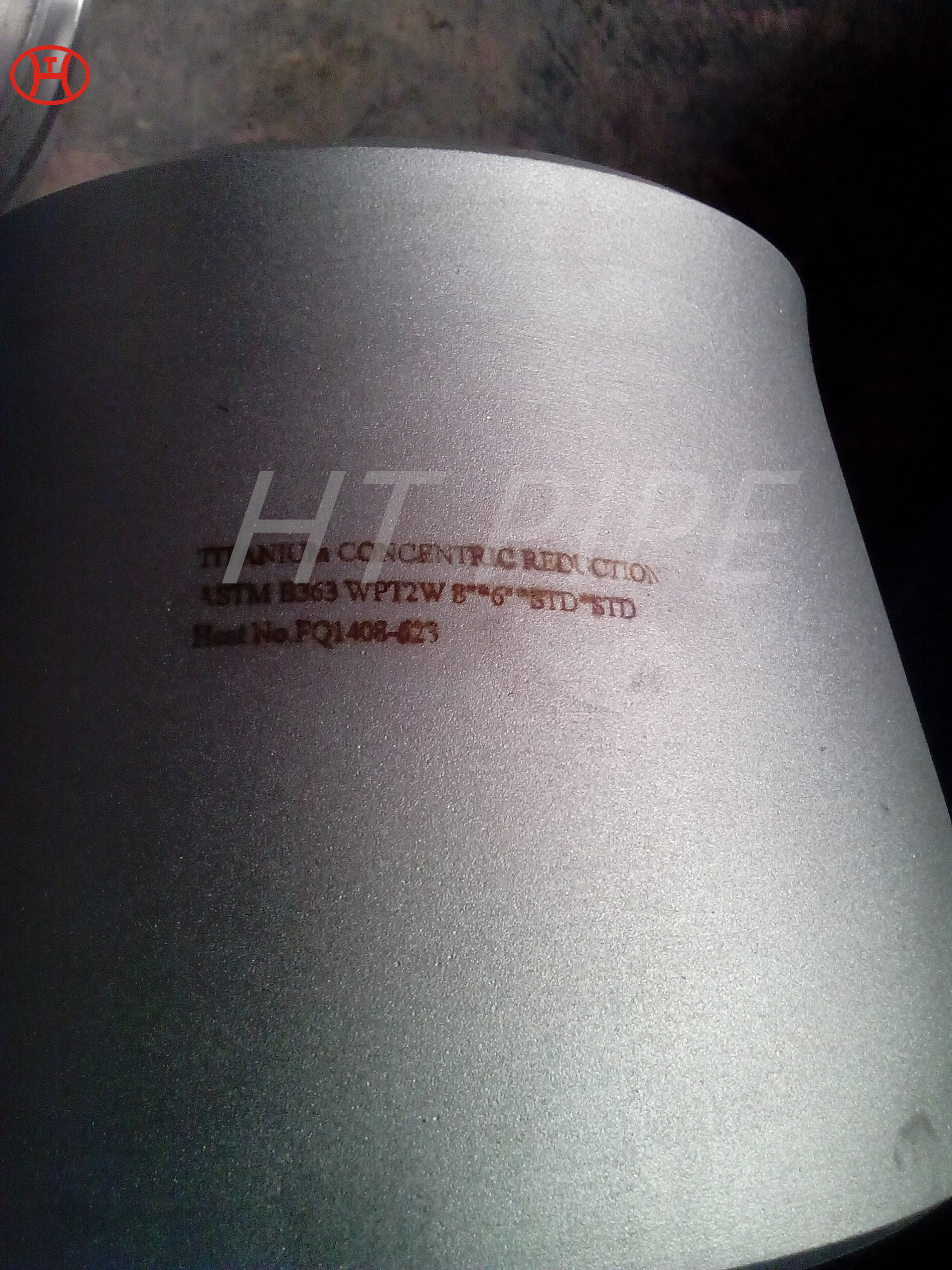

Wrought Austenitic Stainless Steel 304 Pipe Fitting, Stockholder Of Stainless Steel WP304 Tee, ASME SA403M Stainless Steel WP 304 Stub End Wholesaler, Best Price of 304 SS Pipe Cap Exporter, SS Grade WP304 Pipe Elbow, Stainless Steel 304 Seamless Pipe Fittings Traders in China.

Stainless steel 304 elbow is a type of pipe fitting made of stainless steel 304, which is a popular grade of austenitic stainless steel known for its excellent corrosion resistance, high temperature strength, and good weldability.

The elbow is a type of pipe fitting that is used to connect two pipes at an angle, typically 90 degrees. The 304 stainless steel elbow is designed to withstand high pressure, temperature, and corrosive environments, making it suitable for use in a wide range of industrial applications, including chemical processing, food and beverage processing, oil and gas, and pharmaceuticals.

Stainless steel 304 elbows are available in various sizes and configurations, including butt weld, threaded, and socket weld. The type of fitting required depends on the specific application and the type of pipes being connected.

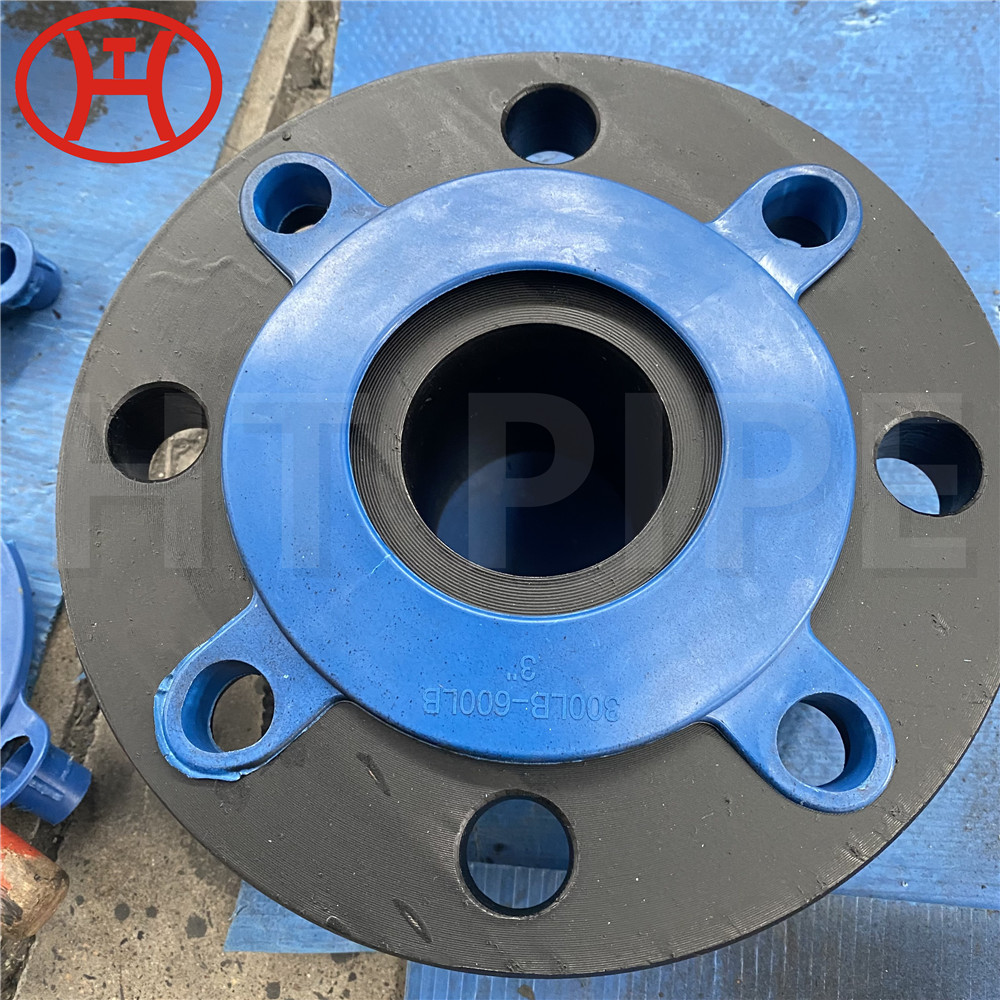

When selecting a stainless steel 304 elbow, it is important to consider factors such as the diameter of the pipes being connected, the angle required, the pressure and temperature requirements, and the corrosive nature of the environment. It is also important to ensure that the fitting is compatible with the type of pipes being connected to ensure a secure and leak-free connection.

Standard Specification For Stainless Steel ASTM A403 WP304 Pipe Fittings

Specifications : ASTM A403 / ASME SA403

Dimensions : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Size : 1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated)

Type : Seamless / Welded / Fabricated

Bending Radius : R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Thickness : Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

| Standard: | ASTM EN DIN GB ISO JIS | Certification: | SGS,ISO,ROHS |

| Length: | 6000-25000mm,etc | Surface: | 2B,2D,BA,NO.1,NO.4,NO.8,8K,Pickling,Bright;mirror,checkered,embossed,hair line, sand blast, Brush, etching, etc |

| Diameter: | 3mm–1000mm, etc | Production Process: | Cold Drawn,Cold Rolled,Bright Anneal etc |

| Thickness: | 0.5-40mm | Surface Treatment: | Standard export package, suit for all kinds of transport, as required. |

| Export Packing: | Waterproof Paper, Steel Strip Packed and other Standard Export Seaworthy Package, or customized package | Loading Port: | Pickled,Passivation,Inside & Outside Mechanical Polishing, BA, Electropolishing (EP) |

| Heat Treatment Condition: | Solution Annealing and water rapid quenched, Bright Annealing,Stess Relieving Heat Treatment for U tubes | Trade Terms: | FOB, CNF,CIF |

| Grade: | 201,202,304,304L,309,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,410S,420(420J1,420J2),430,436,439,441,444,446 etc1.4301, 1.4307, 1.4541, 1.4401, 1.4404 ,1.4571, 1.4438, 1.4539, 1.4547, 1.4529, 1.4562, 1.4410, 1.4878, 1.4845, 1.4828, 1.4876, 2.4858, 2.4819 | ||

| Advantage: | 1. high quality surface, clean finished2. corrosion & oxidation resistance, more durable3. high ductility and good toughness4. high strength and to deform5. the use to diversity | ||

| Container Size: | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) | ||