310S Stainless Steel Pipe Flanges 1.4841 Forged Flanges

The flanges are made from 310S stainless steel, which is a heat-resistant austenitic stainless steel alloy. 310S Stainless Steel Flange contains high levels of chromium (24-26%) and nickel (19-22%) to provide superior corrosion resistance and high-temperature strength.

Stainless Steel 310S Flanges, 310S Stainless Steel Flanges, SS 310S Flanges, ASTM A182 UNS S31008 ASTM A182 F310S Flange, ASME SA182 F310S Flanges Manufacturer.

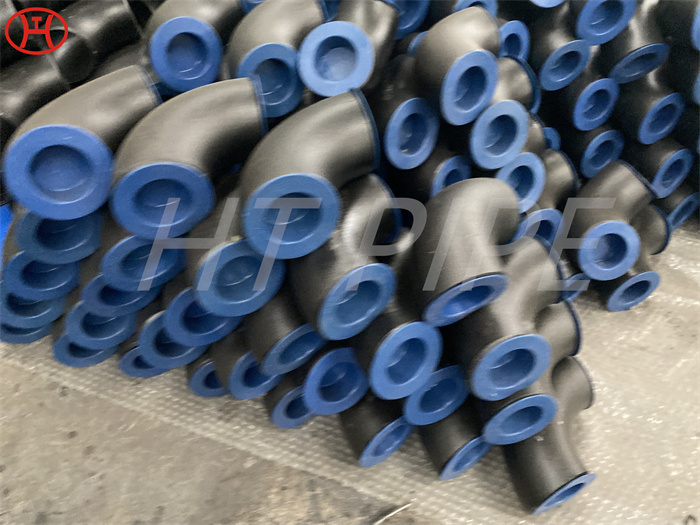

310S Stainless Steel Pipe Flanges 1.4841 Forged Flanges are essential components used in piping systems to connect pipes, valves, and other equipment. In the case of 310S stainless steel flanges, the main features include:

1. Material: The Stainless Steel 310S Blind Flanges are made from 310S stainless steel, which is a heat-resistant austenitic stainless steel alloy. 310S Stainless Steel Flange contains high levels of chromium (24-26%) and nickel (19-22%) to provide superior corrosion resistance and high-temperature strength.

2. Corrosion Resistance: SS 310S Flange exhibits excellent resistance to corrosion in various environments, including high-temperature and oxidizing atmospheres. ASTM A182 UNS S31008 Flange is particularly resistant to sulfidation, carburization, and other forms of high-temperature corrosion.

3. High-Temperature Performance: One of the key features of SS 310S Flange is its exceptional high-temperature resistance. ASTM A182 F310S Flange can withstand elevated temperatures up to approximately 1150°C (2100°F) without significant loss of strength or corrosion resistance.

4. Strength and Durability: 310S stainless steel flanges offer excellent strength and durability, making ASME SA182 F310S Flanges suitable for applications involving high-pressure and high-temperature conditions. ASME SA182 F310S Flanges maintain their integrity and sealing capabilities under demanding operating environments.

5. Weldability: 310S stainless steel is readily weldable using various welding techniques, including TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and submerged arc welding. This facilitates easy installation and joining of the flanges in the piping system.

6. Standard Compliance: 310S Stainless Steel Pipe Flanges 1.4841 Forged Flanges are typically manufactured according to recognized industry standards such as ASME/ANSI B16.5 or DIN. These 310s Weldneck Flanges standards define the dimensions, pressure ratings, and other specifications to ensure compatibility and interchangeability.

Stainless Steel 310s Flange Chemical Compostion and Properties

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 310S | min. max. |

– 0.08 |

– 2.00 |

– 1.50 |

– 0.045 |

– 0.030 |

24.0 26.0 |

– | 19.0 22.0 |

– |

Stainless Steel 310s Flange Mechanical and Physical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| 310S | 515 | 205 | 40 |

7. Flange Faces: 310S stainless steel flanges commonly have raised faces (RF) or ring-type joint (RTJ) faces. The raised face provides a sealing surface when compressed against a gasket, while the RTJ face uses a metal ring gasket for sealing.

8. Size Range: 310s Blind Flanges are available in a wide range of sizes to accommodate different pipe diameters and pressure ratings. Common sizes range from 1/2 inch to 48 inches or larger, with pressure ratings varying based on the design and standards.