316 Lap Joint Flanges Supplier SS Lpj Flanges

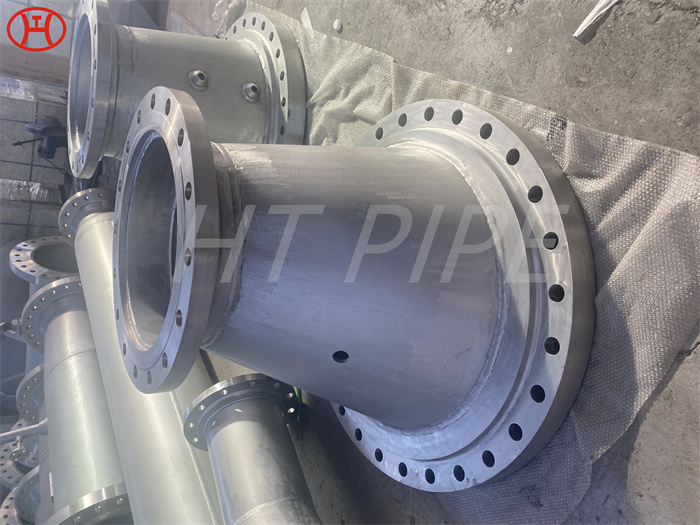

316 Lap Joint Flange is a type of flange that is typically used in piping systems. SS Lpj Flange is designed to connect two pipes or fittings together by overlapping the flanges and then bolting them together. 316 lap joint pipe flanges are used in applications where there is a need for occasional disassembly and assembly of the piping system, for example, to remove a valve or pump.

316 Lap Joint Flanges Supplier SS Lpj Flanges, A182 F316 Lap Joint Flange, ASME SA182 SS 316 Lap Joint Pipe Flanges, SS 316 Lap Joint Flange Stub End, SS DIN 1.4401 Lap Flange Joint, SS 316 Lpj Flange, ASME SA182 SS 316 Lap Joint Flanges, ANSI B16.5 SS 316 Lap Joint Flange And Stub End, 1.4436 Stainless Lap Joint Flange, S31600 Stub End and Lap Joint Flange.

316 Lap Joint Flange is a type of flange that is typically used in piping systems. SS Lpj Flange is designed to connect two pipes or fittings together by overlapping the flanges and then bolting them together. 316 lap joint pipe flanges are used in applications where there is a need for occasional disassembly and assembly of the piping system, for example, to remove a valve or pump.

A182 F316 stub end lap joint flanges are available in standard dimensions like other flange types. ANSI B16.5 SS 316 lap joint flange stub end makes them easy to integrate into existing piping systems or use alongside other piping components like valves, equipment, etc.

Production:

- Material: 316 stainless steel lap joint flanges can be made with a variety of materials, including carbon steel, stainless steel, and alloy steel.

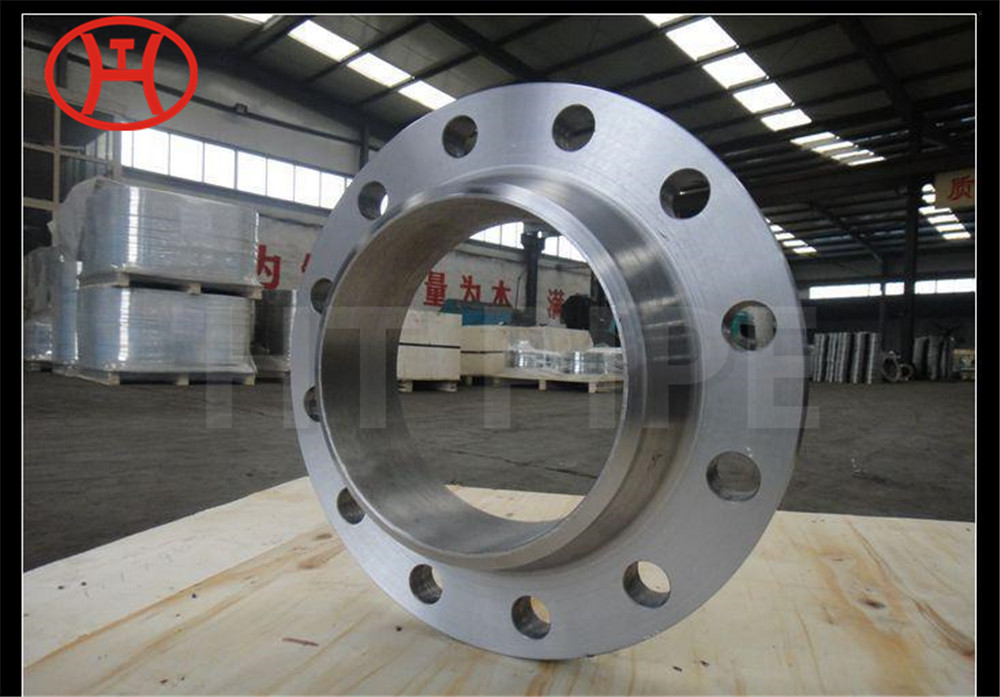

- Size: DIN 1.4401 steel lap joint flanges come in a variety of sizes, ranging from 1/2″ to 24″ and larger.

- Face type: 316 pipe lap joint flanges can be manufactured with different face types, such as raised face, flat face, and ring type joint face.

- Standards: 316 raised face lap joint flanges are manufactured to a number of international standards, such as ANSI, ASME, DIN, EN, and JIS.

Advantages

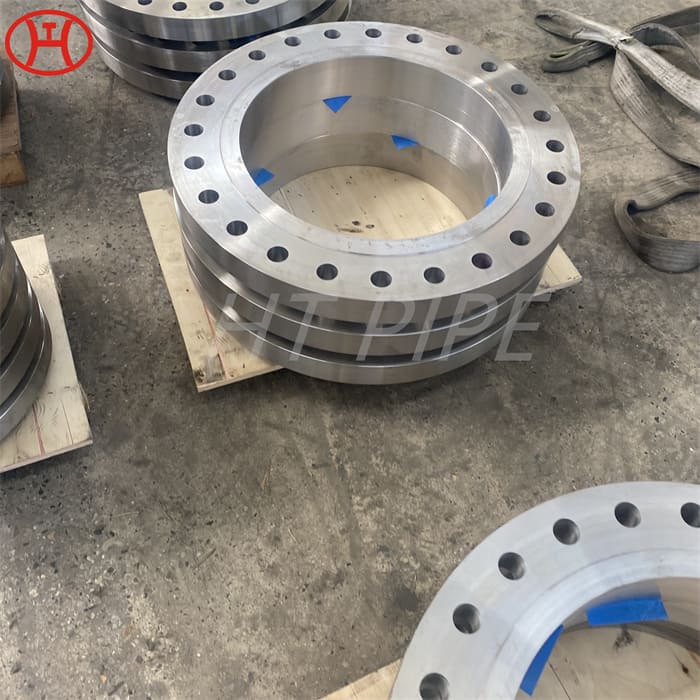

- With SS 316 Lpj Flange, we can use different materials for the Backing flange than the Stub End or Angle Ring. It means you can use the piping material compatible with the fluid passing through the pipe for the stub end and can use more affordable or desirable materials for rotating flange which do not interact with the process fluid.

- ASME SA182 SS 316 Lap Joint Flange is the ability to realign and rotate the flange freely to ensure proper connection with valves and other flanged components of piping systems. SS lap joint flanges greatly speeds up maintenance processes in systems that require frequent maintenance.

- ANSI B16.5 SS 316 Lap Joint Flange And Stub End do not require filet welds on the plates. This fact decreases installation times and provide further upfront cost savings.

In high corrosion and high erosion processes, piping may have to replaced frequently. In such cases, only stub end portion of this flange is needed to be replaced.

Application:

- Chemical industry: ASME B16.5 Lap joint flanges are widely used in chemical plants where there is a need for handling corrosive and hazardous materials.

- Oil and gas industry: Class 150 Lap joint flanges are commonly used in offshore oil and gas drilling rigs, refineries, and petrochemical plants.

- Water treatment: 1.4436 Stainless Lap Joint Flanges are used in water treatment plants, where they are used to connect pipes and valves.

- HVAC systems: Class 600 Lap joint flanges are used in HVAC systems, where they are used to connect air ducts and ventilation systems together.

Standard Specification Of 316 Lap Joint Flanges

| Specifications List | ASTM A182 / ASME SA182 |

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Size Chart | 1/2″ (15 NB) to 48″ (1200NB) |

| ASTM Standards | ANSI/ASME B16.5, B16.48, BS4504, B 16.47 Series A & B, BS 10, EN-1092, DIN, etc. |

| Standard Flange | ANSI, ASME, BS, DIN, EN etc. |