316l 1.4435 pipe fittings elbow and flange

The austenitic structure of 316 stainless steel provides excellent toughness even at low temperatures.

ASTM A403 Gr WP316L Reducer Manufacturer, Refer Dimensions And Price List Of SS 316L Elbow

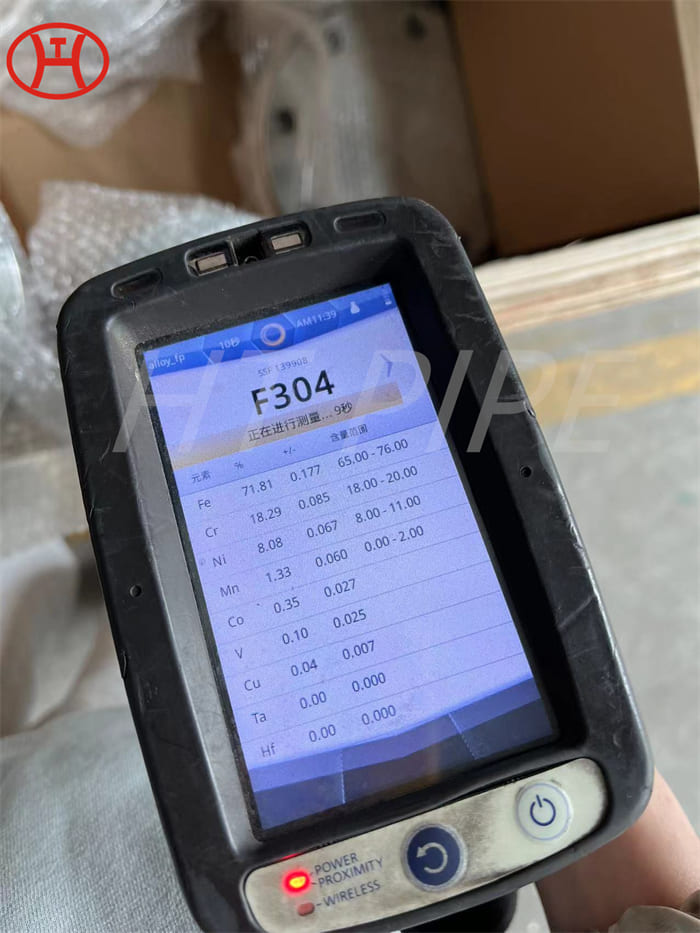

Stainless steel types 1.4401 and 1.4404 are also known as grades 316 and 316L respectively. Grade 316 is the second most commercially important austenitic grade after 304. 316 stainless steel has molybdenum added to make it more resistant to corrosion. 304 stainless steel is the most common stainless steel formulation used in industrial and consumer applications. For chromium and nickel alloys, 304 resists many corrosion attacks. SS 316L Elbow is also popular in a wide range of applications because post-weld annealing (a process of reheating and slow cooling that relieves stress in the metal after exposure to high temperatures) is not required.

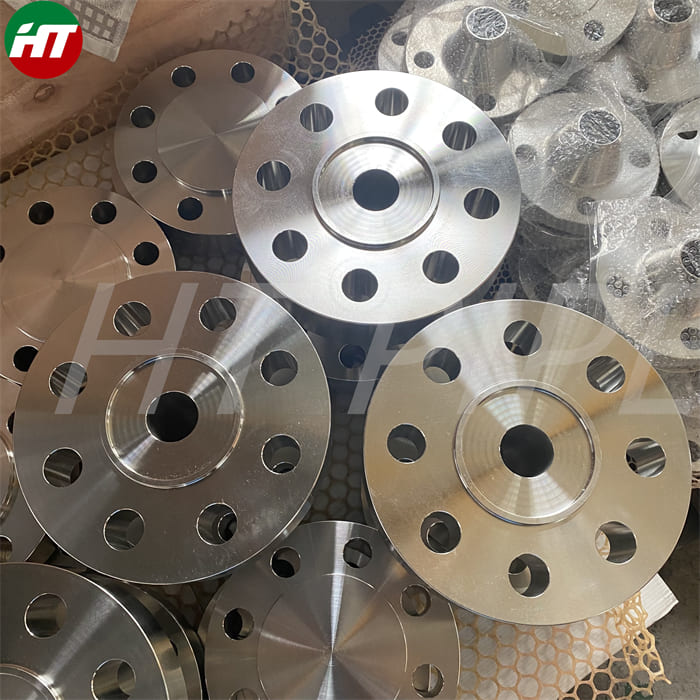

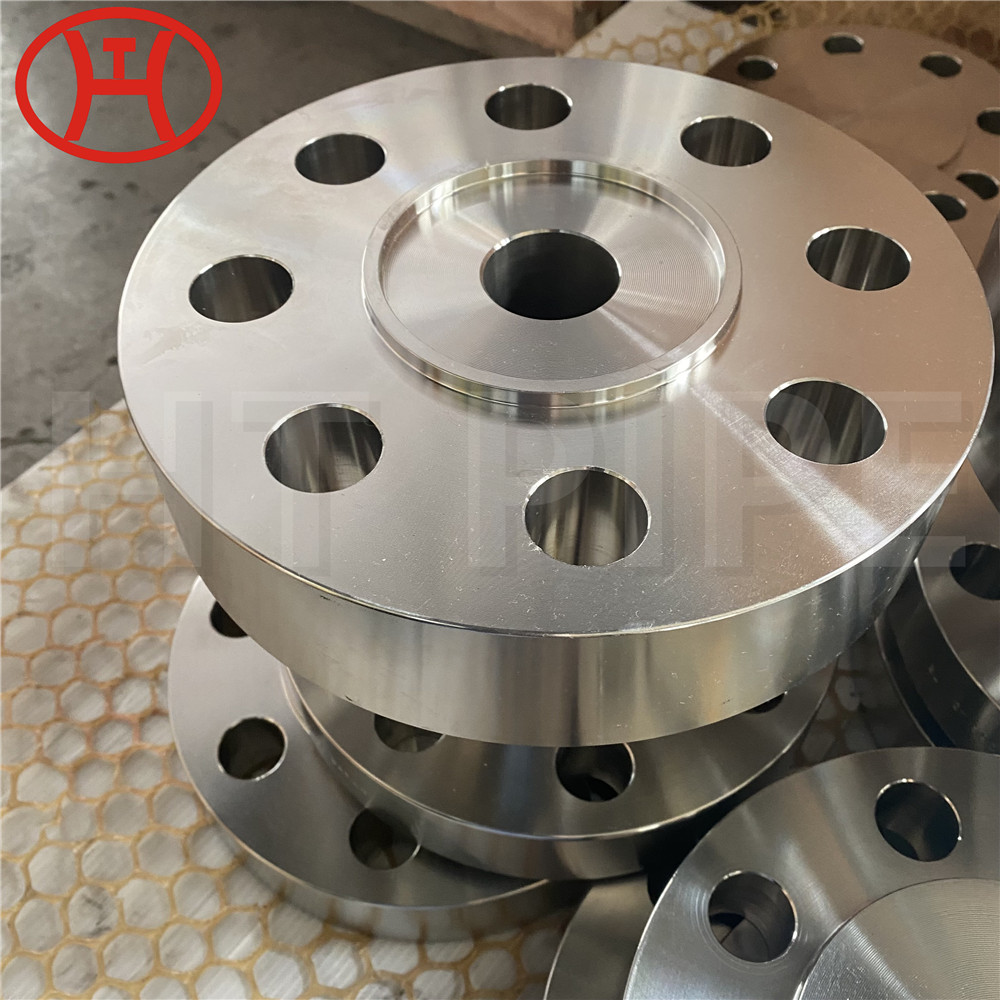

The 316L fittings belongs to low-carbon austenitic stainless steel grade. Stainless Steel 316L Pipe Fittings are versatile piping equipment that is employed to connect piping grades efficiently in different specifications. These SS 316L Elbows are nickel, chromium, and molybdenum grades that work well in harsh conditions. The 316L Stainless Steel Pipe Fittings play a critical role in influencing the characteristics of the fluid and gaseous flow in the system. These SS 316L Elbows have good corrosion resistance properties in harsh conditions. The low carbon in the SS 316L Pipe Fittings prevents post-weld graining and allows them to be easily welded following standard welding procedures. The Stainless Steel 316L Pipe Fittings / ASTM A403 WP316L possess a density of 8000 kg/m3 with an elastic modulus of 193GPa. These fittings have an electric resistivity of 740 nΩ.m.

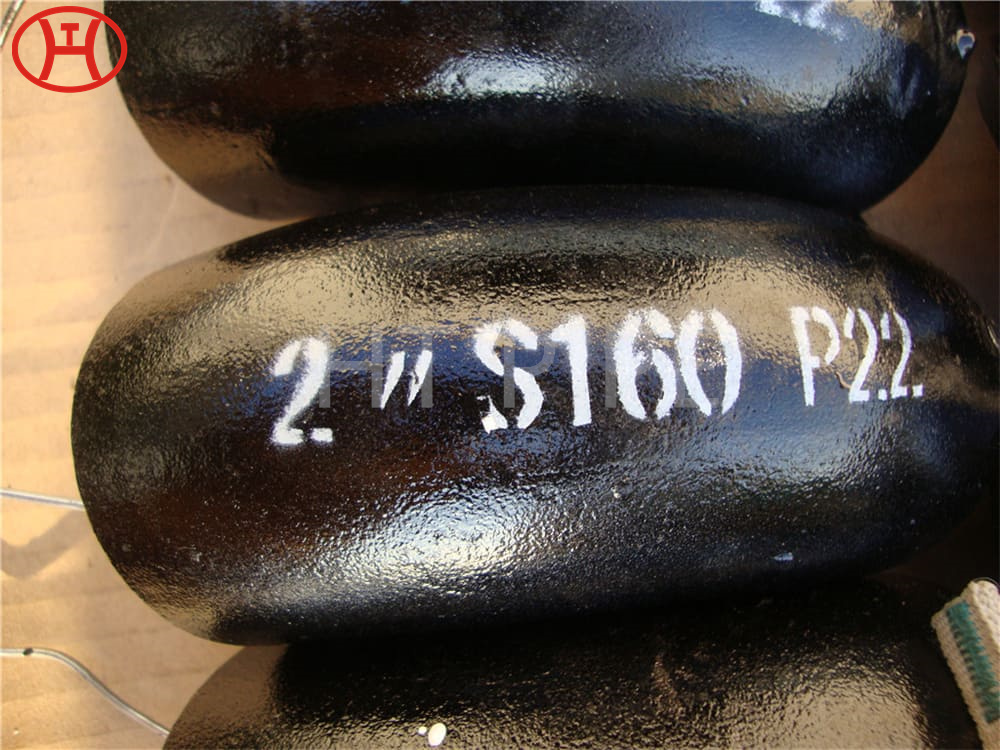

The ASTM A403 WP316L grade is a wrought carbon grade that possesses excellent toughness and offers higher creep and stress rupture properties. The versatile ASTM A403 Gr WP316L components work well in high as well as in cryogenic temperatures. They possess resistance to pitting and crevice corrosion. ASTM A 403 WP 316L is very durable across acidic and chemical toxicants. The grade has a specific thermal capacity of 500 at 20°C J/kg K. The robust A403 WP316L module has a minimum tensile strength of 485mpa with a minimum yield strength of 170mpa and can be elongated by 40% in the system. The SA 403 WP 316L is a pressurized vessel grade that works well in extreme pressure and temperatures in stress-induced conditions. An SA403 WP316L grade can be annealed at temperatures between 1010 to 1120 degrees C, followed by a rapid cooling process. The SS316L Elbow is a key device of a pressurized piping system that helps in changing the direction of fluid and gaseous media. These elbows are designed in long or short radius configurations.

Stainless Steel 316L Pipe Fittings Specifications

| Standards | ASME, ASTM |

| Designation | SA 403, A 403 |

| Thickness | Schedule 5s, to Schedule XXS |

| Grade | Stainless Steel 316L Buttweld Pipe Fittings, SS 316L Butt weld |

| Two Joint / Two Halve Butt weld Fittings Size | 6″ upto 48″ |

| Size | 1/2″ upto 24″ |

| Type | Welded and Seamless |

| Dimension Standard | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Types of Butt weld Fittings | Bend, Swage Nipple, Cap, Short Stubend, 180 Deg Elbow, Eccentric Reducer, Piggable Bend, Long Stubend, 90 Deg Elbow, 1D Elbow, End Cap, Reducer, Barrel Nipple, Long Radius Elbow, Reducing Nipple, Nipple, Short Radius Elbow, Equal Tee, 5D Elbow, Tee, 3D Elbow, Long Radius Bend, Reducing Tee, Elbows, Stubend, 45 Deg Elbows, Concentric Reducer |