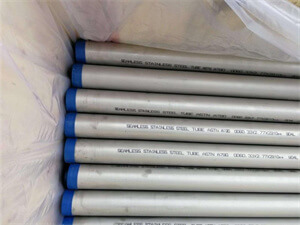

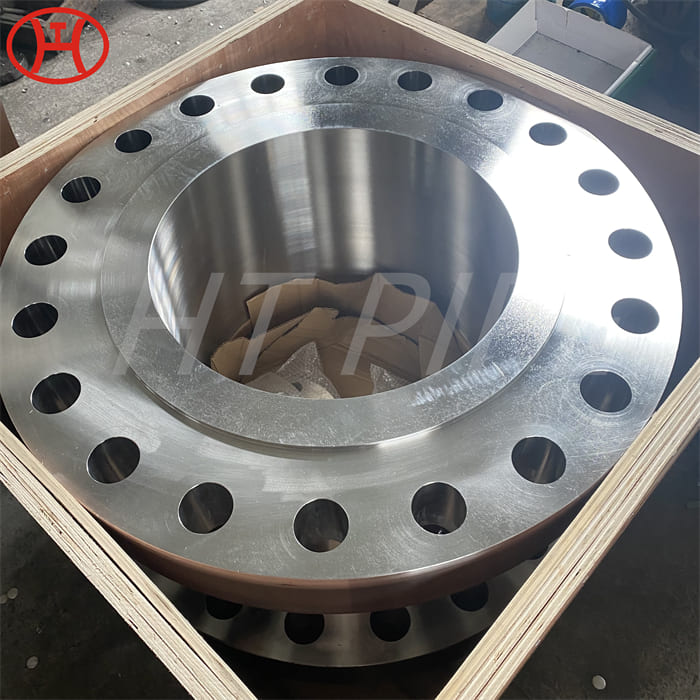

316L S31603 1.4401 mcmaster-carr stub end

The austenitic structure of 316 stainless steel provides excellent toughness even at low temperatures.

Contact US

Get Price

Share:

Content

316L stainless steel is almost the same as 316. The only difference is the carbon content. The low carbon content of 316L imparts better corrosion resistance than 316. 316L does not require post weld annealing.

Types 316 and 316L are molybdenum-containing austenitic stainless steels that are more resistant to general corrosion and pitting/crevice corrosion than conventional chromium-nickel austenitic stainless steels such as Type 304. These alloys also have higher creep, fracture stress and tensile strength at elevated temperatures. Types 316 and 316L typically contain 2% to 3% molybdenum for improved corrosion resistance.

Inquiry

More Stainless steel