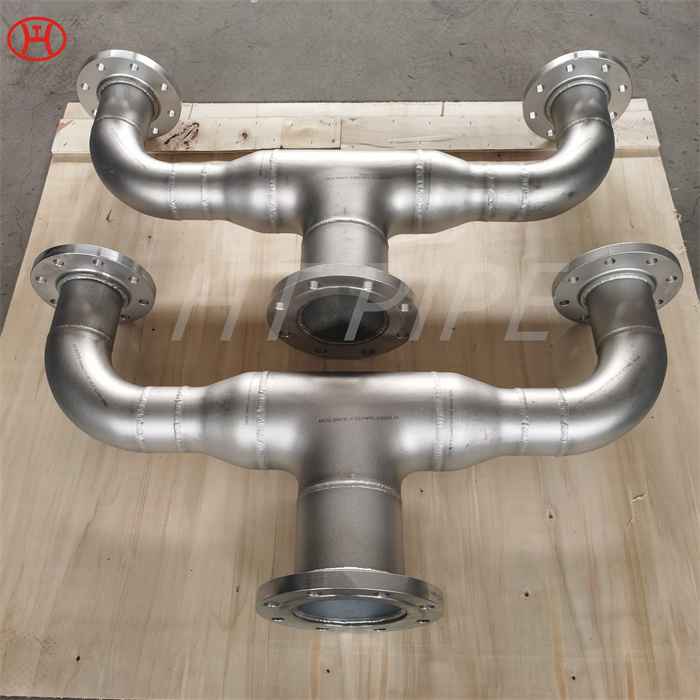

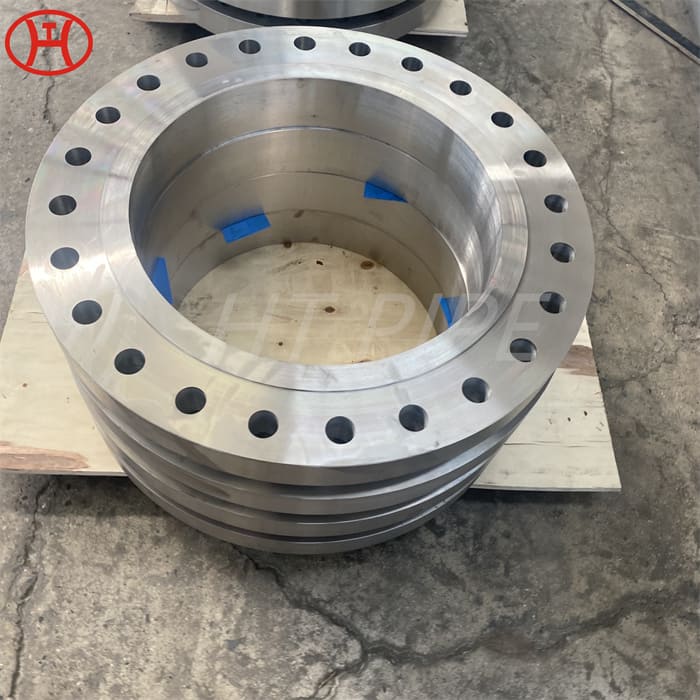

316L S31603 1.4401 stub end flange

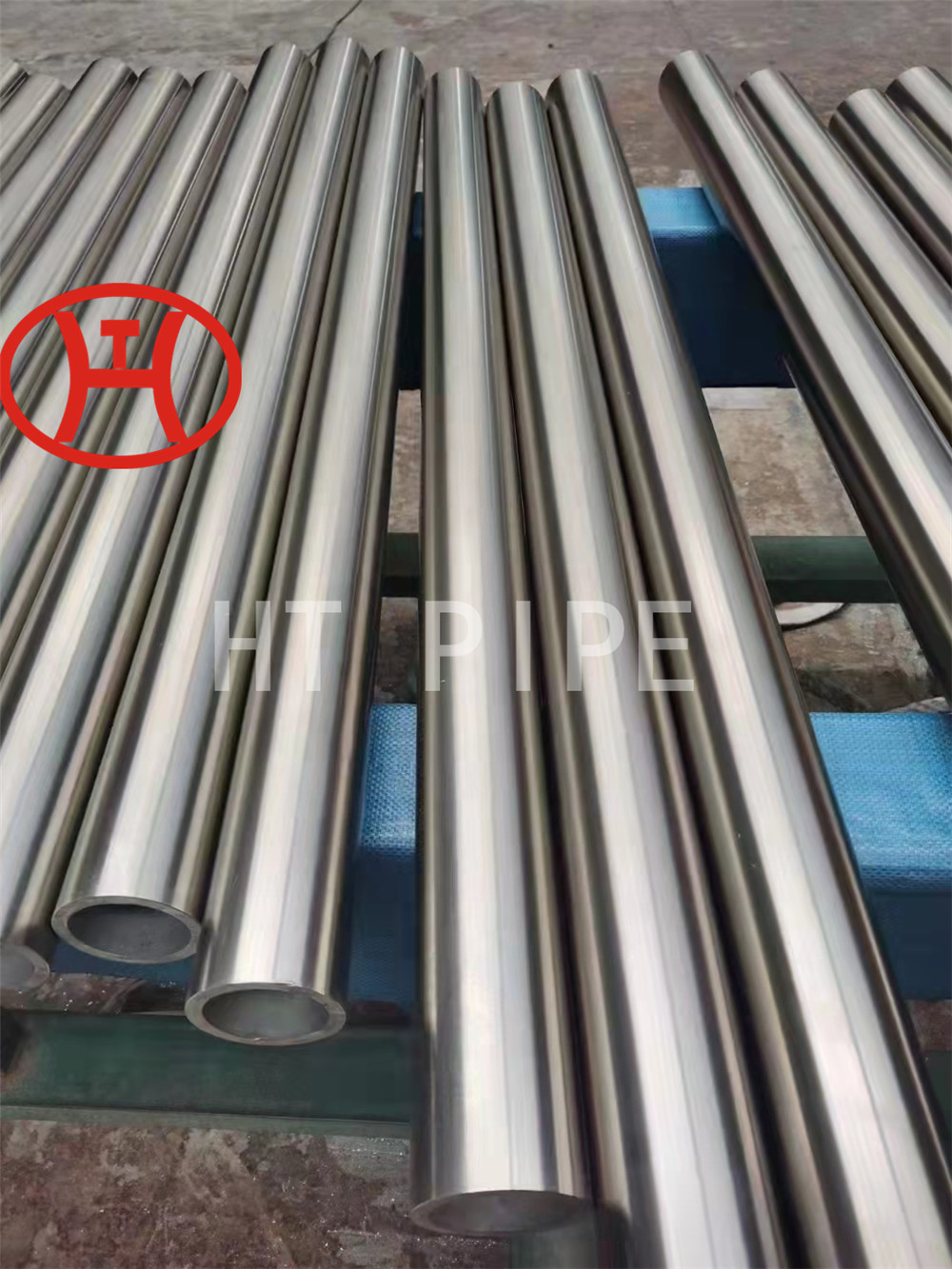

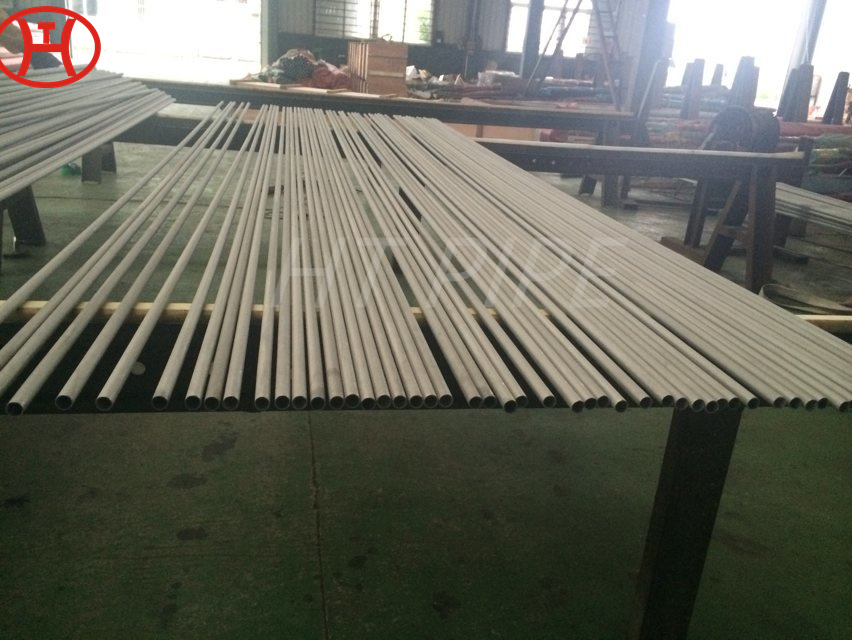

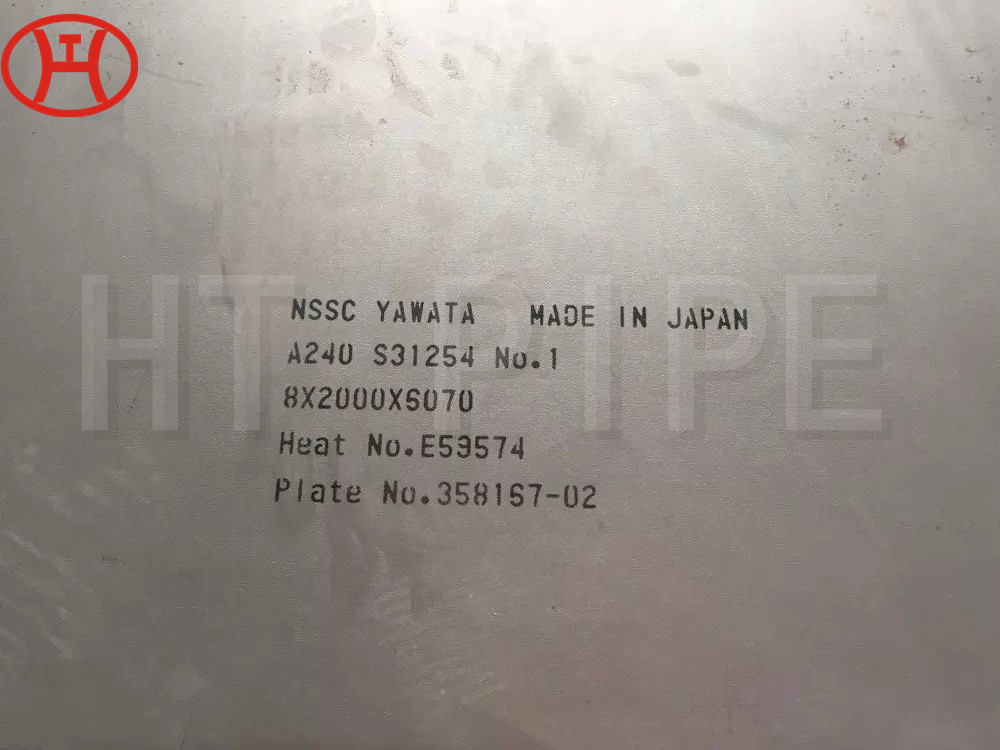

316L stainless steel is an austenitic alloy often referred to as “marine grade stainless steel” because it is used in nearly 90% of marine applications – including filtration. In addition to metals such as iron and nickel, 316L contains 16-18% chromium and 2-3% molybdenum. These elements are important because they improve the alloy’s corrosion resistance; chromium interacts with oxygen in seawater to form a protective layer of chromium oxide, while molybdenum improves the metal’s resistance to pitting corrosion. Additionally, 316L has a lower carbon content (hence the use of “L” in its name), which gives it better protection against corrosion.

Stainless steel is an iron-based alloy containing at least 10.5% chromium. They achieve their stainless steel properties by forming an invisible and adherent chromium-rich oxide film. Alloy 316 is a general purpose austenitic stainless steel with a face-centered cubic structure. It is essentially non-magnetic in the annealed state and can only be hardened by cold work. Molybdenum has been added to improve corrosion resistance, especially in chloride-containing environments. The lower carbon content of Alloy 316L provides better corrosion resistance in welded structures.