347 pipe and spool drawings be considered for exposures

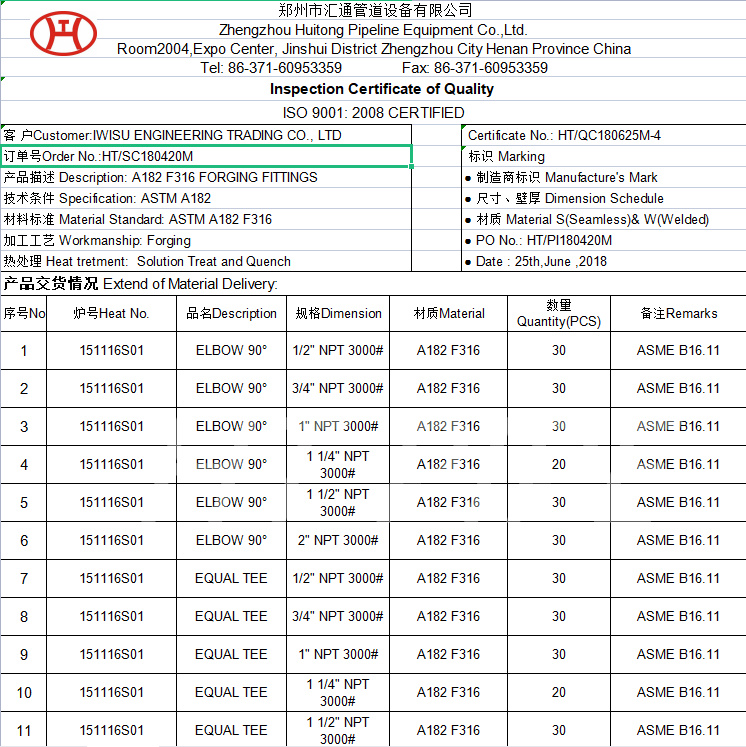

It can be easily welded and processed by standard shop fabrication practices.

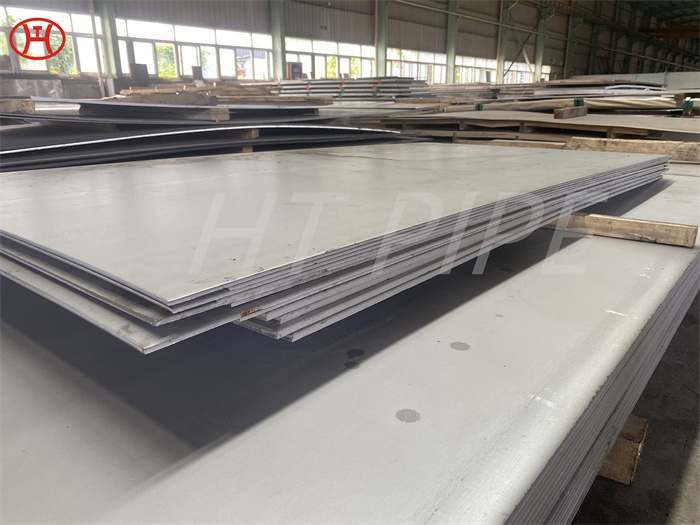

The most notable difference is its resistance to intergranular corrosion. This resistance to intergranular corrosion makes Type 347 particularly suitable for welding applications. Since welding heats the austenitic stainless steel to or above its sensitization temperature range, intergranular corrosion can be a problem. The Type 347 is used in aircraft manifolds and exhaust manifolds, expansion joints and high temperature chemical process equipment. 347 stainless steel is a niobium/tantalum stabilized austenitic chromium-nickel stainless steel. Type 347 has excellent resistance to intergranular corrosion and oxidation. at high temperature. By adding niobium and tantalum, this material prevents the formation of chromium carbides.