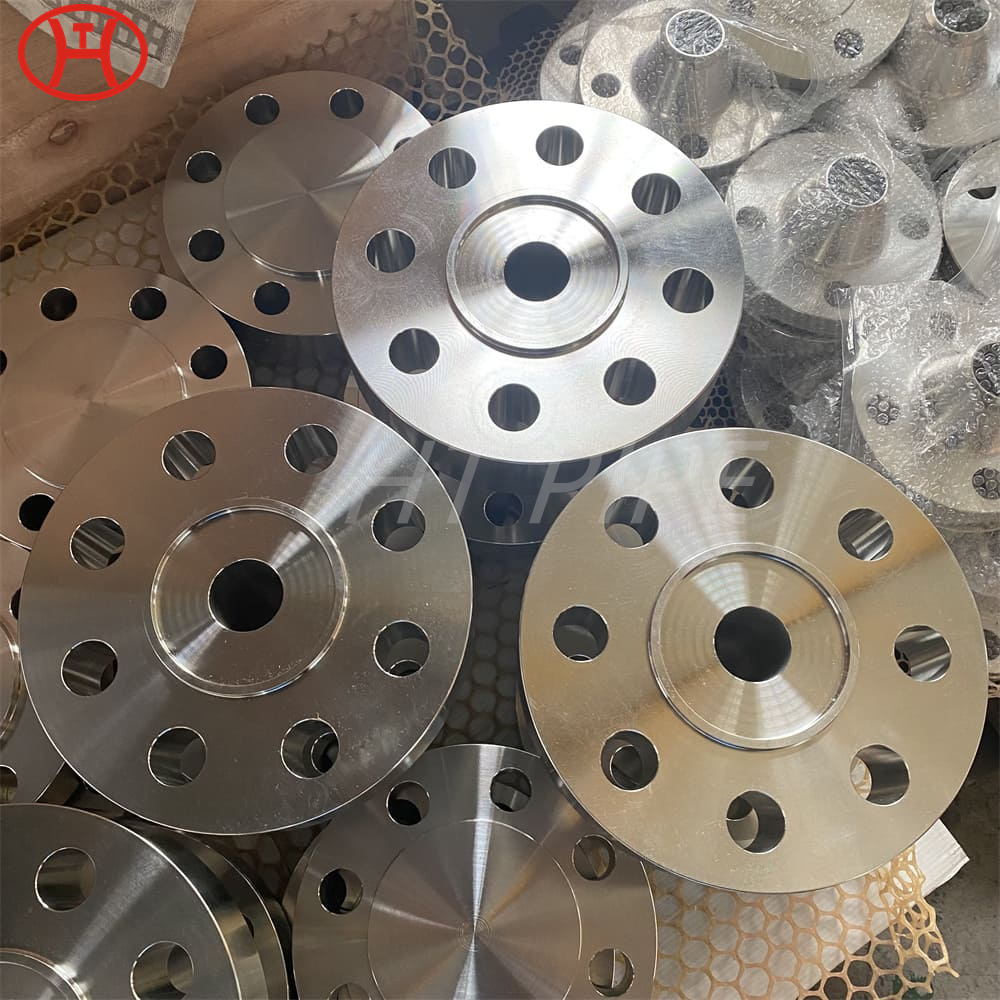

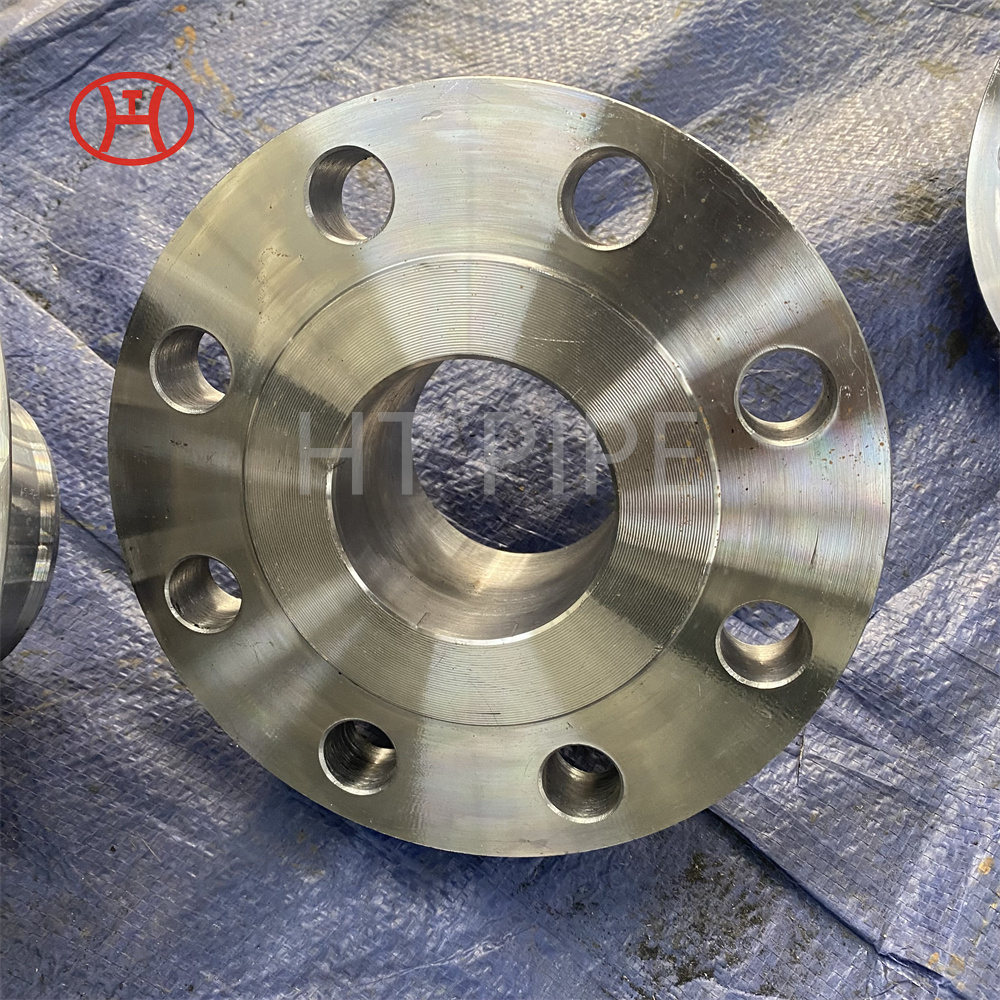

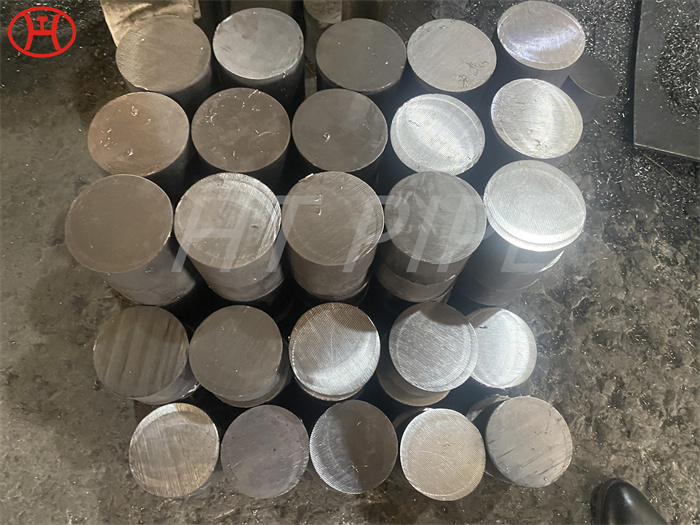

400mm dia nickel alloy flange loosing expansion joint inconel 625

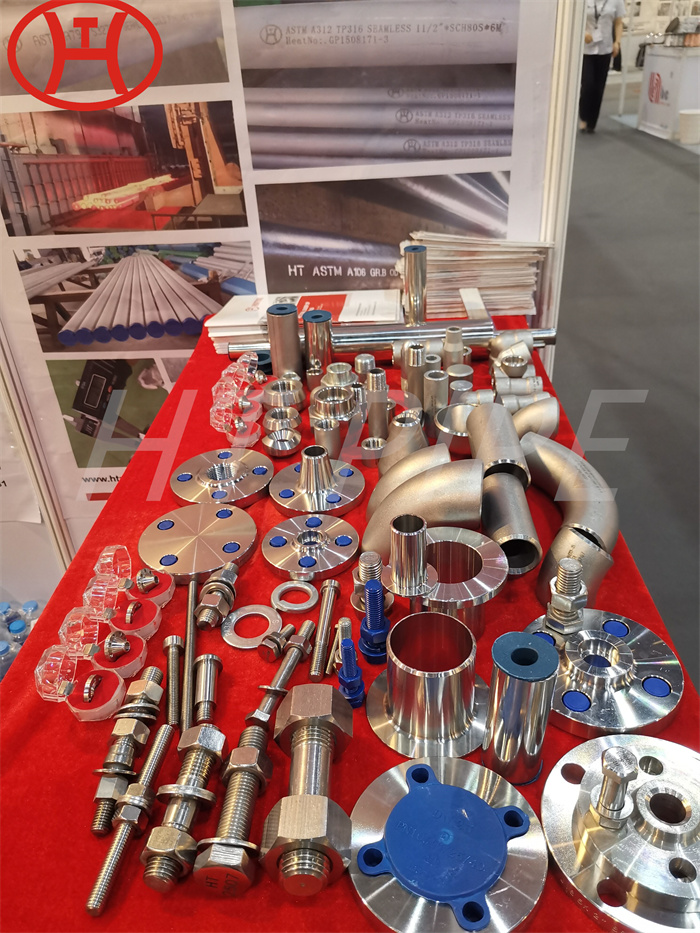

Potential applications for the Inconel 625 Material are bellows for submerged controls, electrical cable connectors, springs, seals, fasteners, flexure devices, and oceanographic instrument components. HT PIPE maintains a large inventory of Inconel 625? flanges, with a variety of sizes, styles, and configurations available to meet your needs. Our Inconel flanges meet the requirements of numerous national and international specifications, including, but not limited to:

N06625

ASTM B564

ASME SB564

WERKSTOFF Nr 2.4856

Inconel 625 Flanges Suppliers, Inconel 625 flanges, Inconel 625 SO flanges, Inconel 625 weld neck flanges, Inconel 625 blind flanges & Inconel 625 flat face flanges stockholders

Inconel 625 exhibits high resistance to corrosion and oxidation, high strength and toughness, and excellent fatigue strength. This nonmagnetic, nickel-based alloy also offers an extremely broad working temperature range—from cryogenic to 2,000°F (1,093°C).

Inconel 625 Flanges are made up of a corrosion resistant and strong nickel chromium alloy that has 58% nickel and 20% chromium in the composition with carbon, manganese, silicon, sulfur, copper and iron. Navstar Steel is a leading supplier and manufacturer of the Inconel 625 Flanges in different scales and types. The flange material has very high tensile strength of 930MPa and minimum yield strength of 517MPa. This strong material also has 1350 degrees Celsius melting point. This makes the flanges be applied in some of the tough and stressful applications.

There are different types of flanges such as the Alloy 625 Slip On Flange and others. All these types belong to the specifications ASTM B564 for nickel alloy, Inconel, monel and hastelloy falnges. The sizes range from ½ inches to 60 inches depending on the type of the flanges. The UNS N06625 BLRF Flange is one of a kind that has a blind and raised face. The blind flanges are used to terminate a connection. They come with a raised face when extra surface for welding or bolting is necessary. The flanges can come under the ANSI, ASME B16.5, B16.47 and other standards.