60000PSI tensile strength Inconel 718 N07718 hex nuts

Inconel Alloy 718 is a high-strength, corrosion-resistant nickel-chromium material that can be used in temperatures from -423¡ã to 1300¡ãF. Alloy 718 for the petroleum industry is heat treated to a hardness not exceeding 40HRC, the maximum value allowed by NACE MR-01-75 to prevent stress corrosion cracking.

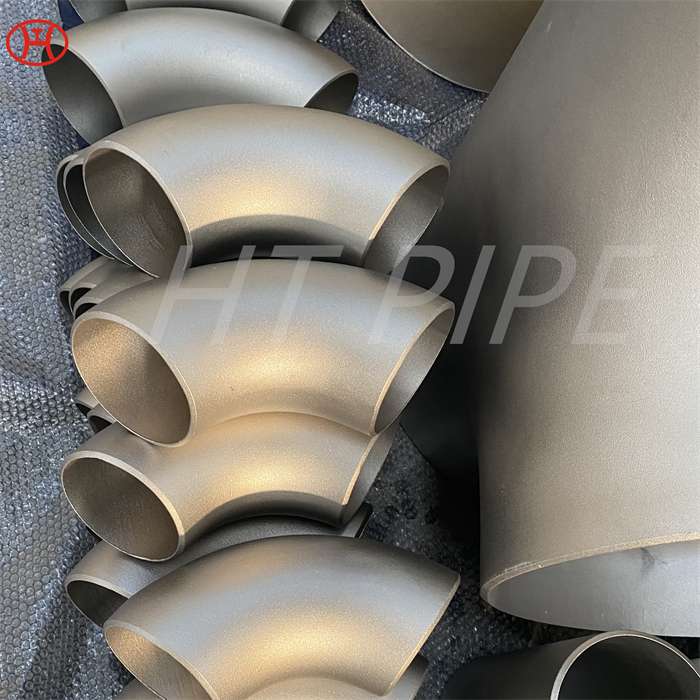

718 fasteners have been used in jet engines and high-speed airframe parts such as buckets, wheels, spacers, and high-temperature fasteners and bolts. ASTM B637 UNS N07718 hot working is performed using a maximum furnace temperature of 2050¡ãF (1121¡ãC). Hot and cold working in the 1700/1850¡ãF (927/1010¡ãC) range will increase the strength of the forging if the service temperature is below about 1100¡ãF. Additionally, 718 Fasteners Alloy 718 for aerospace and power generation is heat treated to provide maximum strength and high creep resistance, with typical hardness values in excess of 42HRC. Primary applications are components for gas turbines, aircraft engines, fasteners and other high-strength applications.