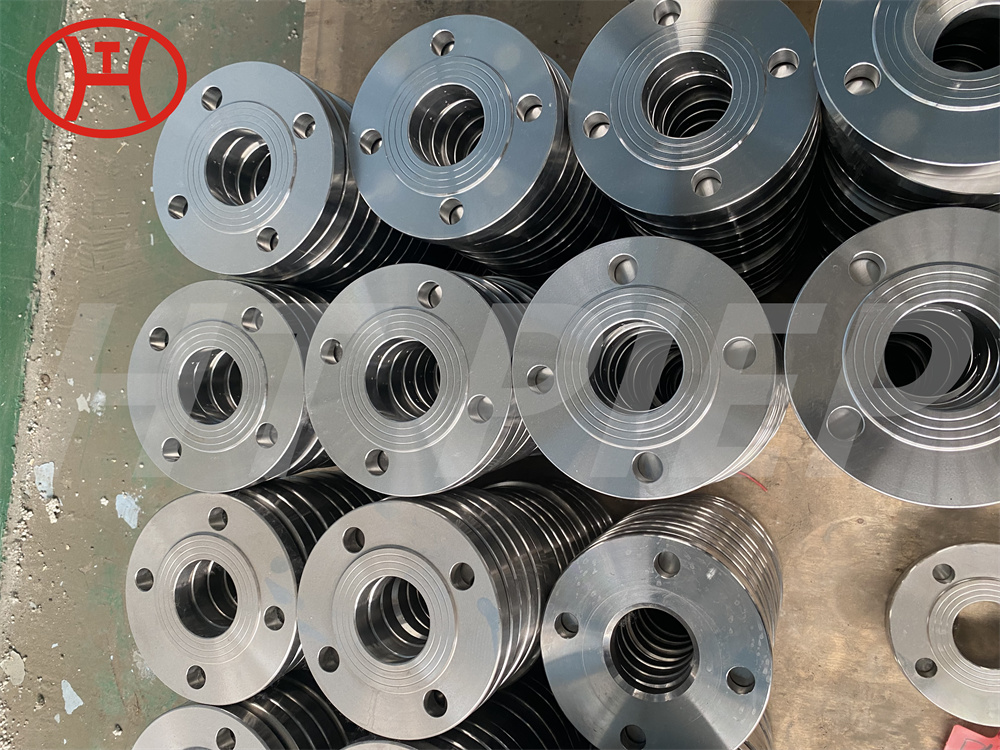

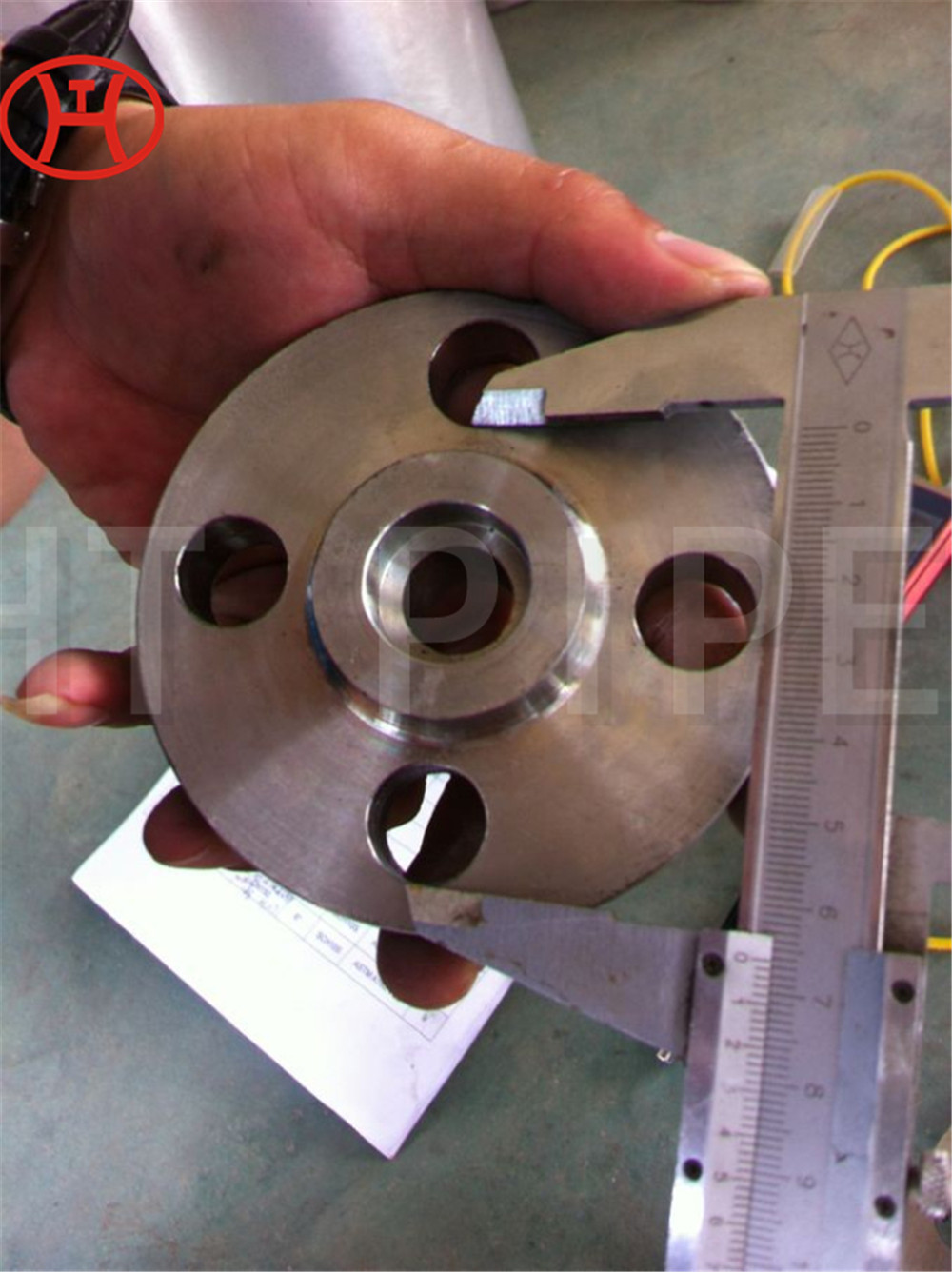

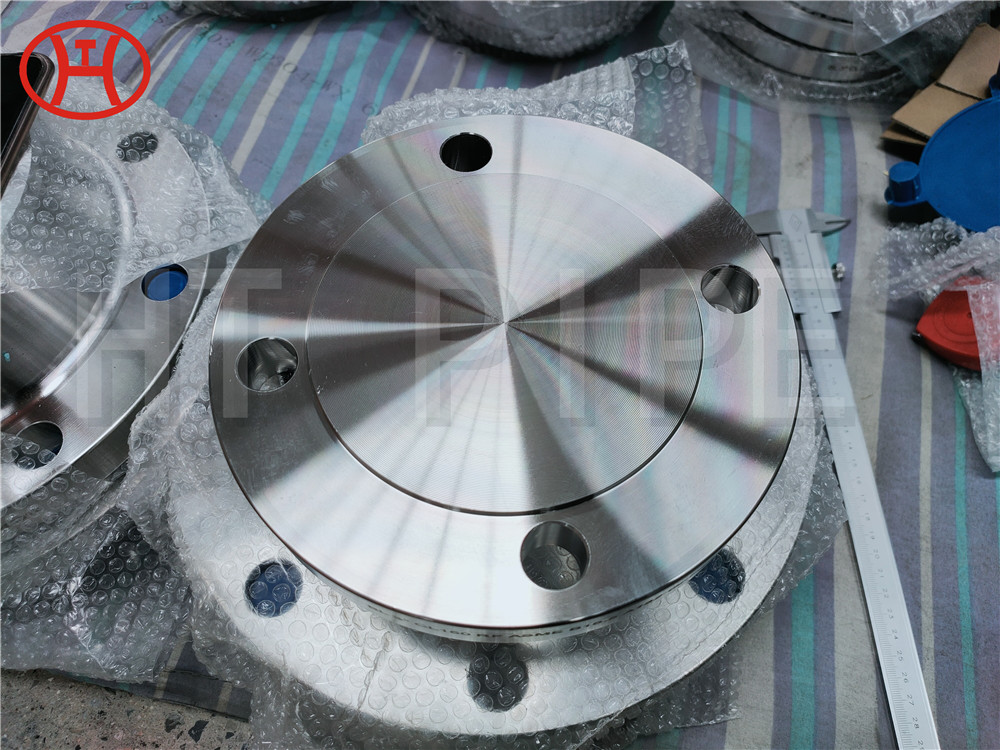

904L N08904 plate in a wide range of machining environments

The SS 904L coil is used in heat exchangers and in high temperature applications because of their high melting range of 1300 to 1390 degrees Celsius.

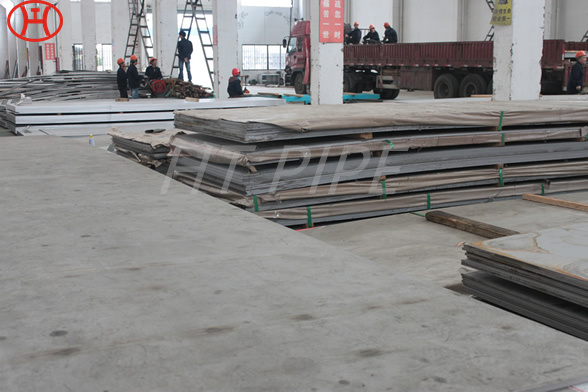

904l stainless steel plate is a super austenitic stainless steel designed for use in moderately to highly corrosive environments. Stainless steel 904l plates have a nickel content of 25% and a molybdenum content of 4.5%. ASTM A240 UNS N08904 plates have good resistance to chloride stress corrosion cracking, pitting and general corrosion. The addition of copper to SS 904l sheet improves resistance to sulfuric acid under aggressive and mild conditions, and also has good resistance to other inorganic acids such as hot phosphoric acid, as well as most organic acids. Adding nitrogen to DIN 1.4539 plate can provide more powerful processing equipment. Nitrogen can form a stable nitride with chromium, nickel and other elements, which can enhance the corrosion resistance of 904l stainless steel plate. It can improve the strength and hardness of 904L plate, making it more suitable for use under high strength and high temperature.

904l stainless steel sheet application:

Air Pollution Control: Scrubbers for Coal-Fired Power Plants

Chemical processing: process equipment for the production of sulfuric acid, phosphoric acid, inorganic and organic acids and the production of phosphate fertilizers

Oil and Gas Production: Offshore Processing Equipment

Pulp and Paper: Processing Equipment

Seawater and brackish water: condensers, heat exchangers and piping systems

ASTM A240 904l stainless steel plate specification

| Type | Plate, Sheet,Strip Coil | |||||||

| Length | 0~12m or as per your requirements | |||||||

| Width | 0~2500mm or as per your requirements | |||||||

| Thickness | 0.3~1200mm or as per your requirements | |||||||

| Process | Hot/Cold Rolled Type | |||||||

| Surface | No.1 No.2D No.2B BA No.3 No.4 No.6 No.7 | |||||||

| Packing | Steel Frame, waterproof paper, wooden pallet, wooden case or as per the client’s requirements | |||||||