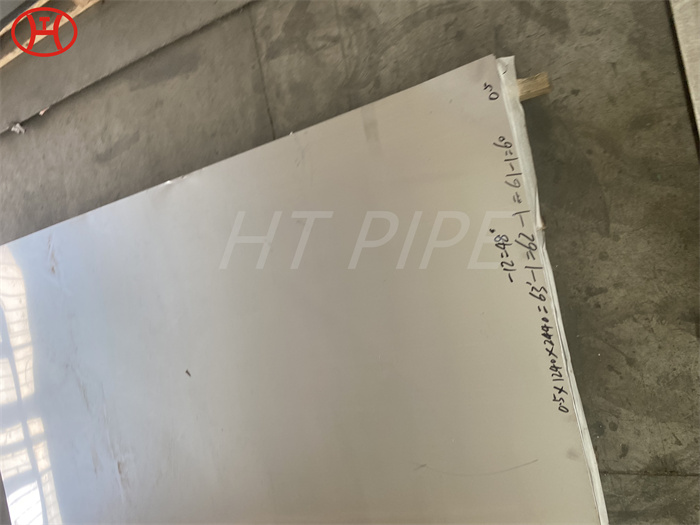

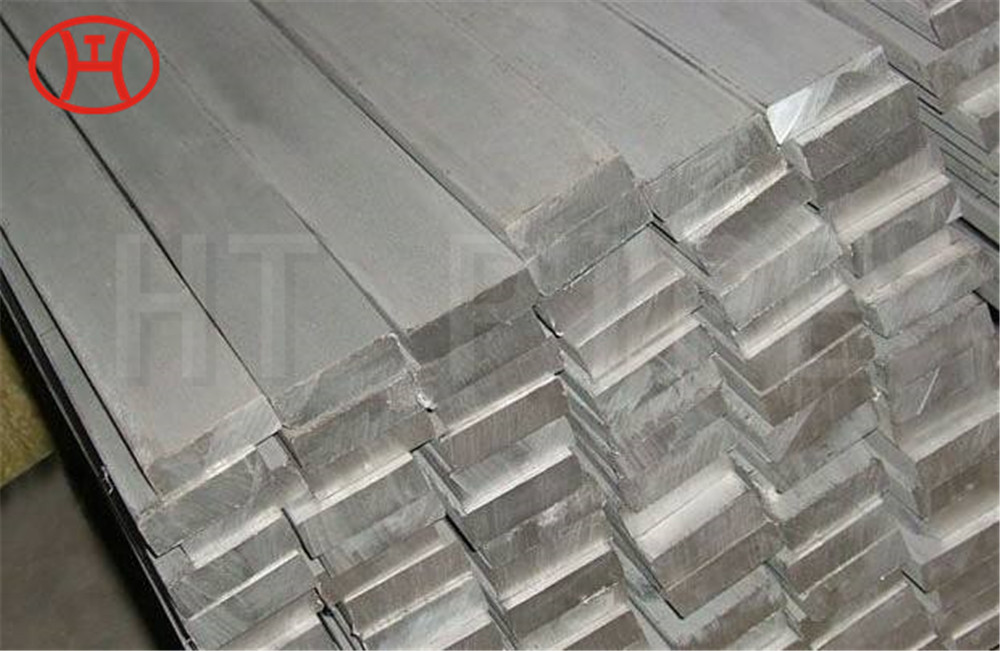

904L N08904 plate used in the chemical process industry

The 1.4539 Plate is a standard which governs the thickness of the sheets and plates. There are different specifications to cover the sheets and plates as well.

The corrosion resistance of grade 904L is intermediate between super austenitic grades, with 6% molybdenum content, and standard 316L austenitic grades.

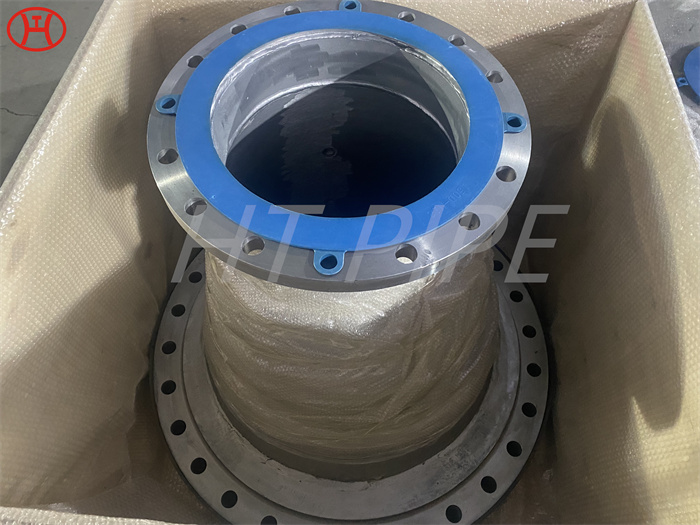

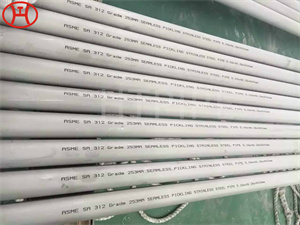

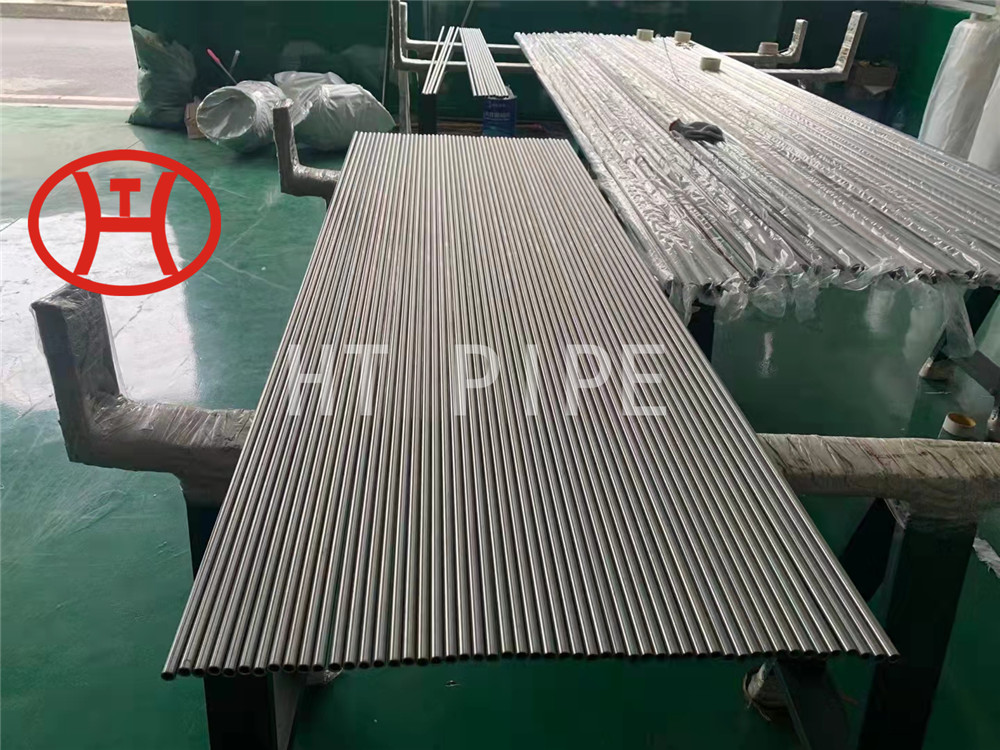

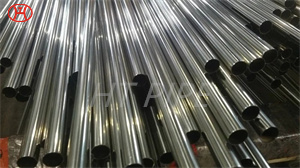

The resistance properties of grade 904L stainless steel pipes include good resistance to stress corrosion cracking, and pitting and crevice corrosion, as well as inter granular corrosion. The ¡°L¡± in 904L stands for low carbon, i.e., only 0.03 percent or less. Grade 904L is also non-magnetic in all conditions, and has excellent machinability and weldability. Moreover, the austenitic structure gives it excellent toughness, even at cryogenic temperatures.

This 904L stainless steel plate has a minimum tensile strength of 70 ksi and a yield strength of 25 ksi. It has a maximum hardness of 150 HB and elongation of 35%. The plate has low carbon content, usually less than 0.02%; this helps to prevent sensitization during welding or exposure to high-temperature environments.