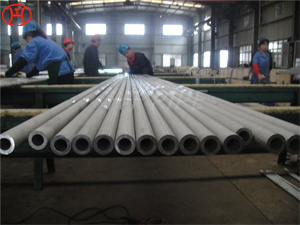

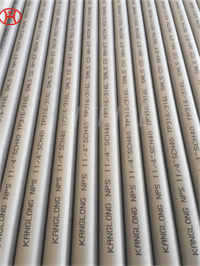

904L pipe prefabrication greater resistance reducing acids

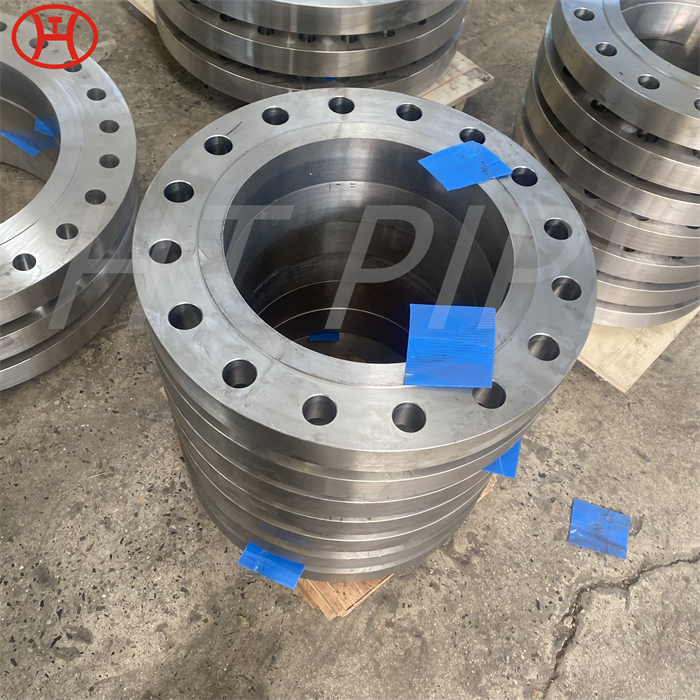

The high chromium content promotes and maintains a passive film that protects the material in many corrosive environments.

904L is more resistant to ferrite and sigma-phase precipitation during cooling and welding than other molybdenum-containing stainless steels such as 316L and 317L. The thermal conductivity of austenitic steels is only 30% of that of unalloyed steels. They have lower melting points than unalloyed steels, so austenitic steels must be welded with lower heat input than unalloyed steels. Alloy 904L (UNS N08904) is a super austenitic stainless steel designed to provide moderate to high corrosion resistance in a variety of process environments. The combination of high chromium and nickel content, with the addition of molybdenum and copper, ensures good corrosion resistance.