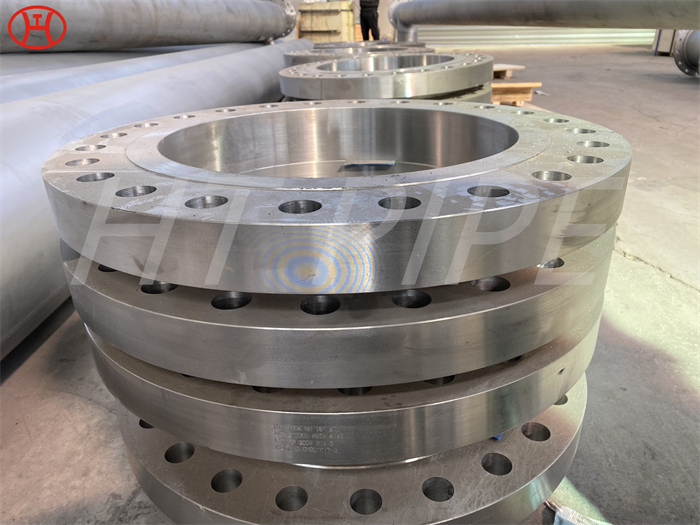

904L pipe prefabrication resistance to pitting and crevice corrosion

Alloy 904L outperforms other austenitic stainless steels due to the higher degree of alloying of nickel and molybdenum.

This grade is non-magnetic under all conditions and has excellent formability and weldability. The austenitic structure also gives this grade excellent toughness, even at low temperatures. When selecting filler metals, corrosion stress must also be considered. Due to the cast structure of the weld metal, it may be necessary to use a higher alloyed filler metal. This steel does not require preheating. Heat treatment after welding is usually uncommon. Because of all the advantages of using Type 904L stainless steel, it can be found in many applications in a variety of critical industries, including seawater cooling equipment, chemical processing of sulfuric, phosphoric, and acetic acids.