904L SS Welded Tube Exporter ASTM A358 Stainless Steel 904L EFW Pipe

904L is having very good resistance ability against reducing acids and the addition of copper is giving it general corrosion resistance to various concentrations of the sulphuric acid.

X1NiCrMoCu25-20-5 Stainless Steel Pipes, SS 904L ERW Pipes, Stainless Steel 904L Seamless Pipe, Stainless Steel 904L Pipes Manufacturer in China.

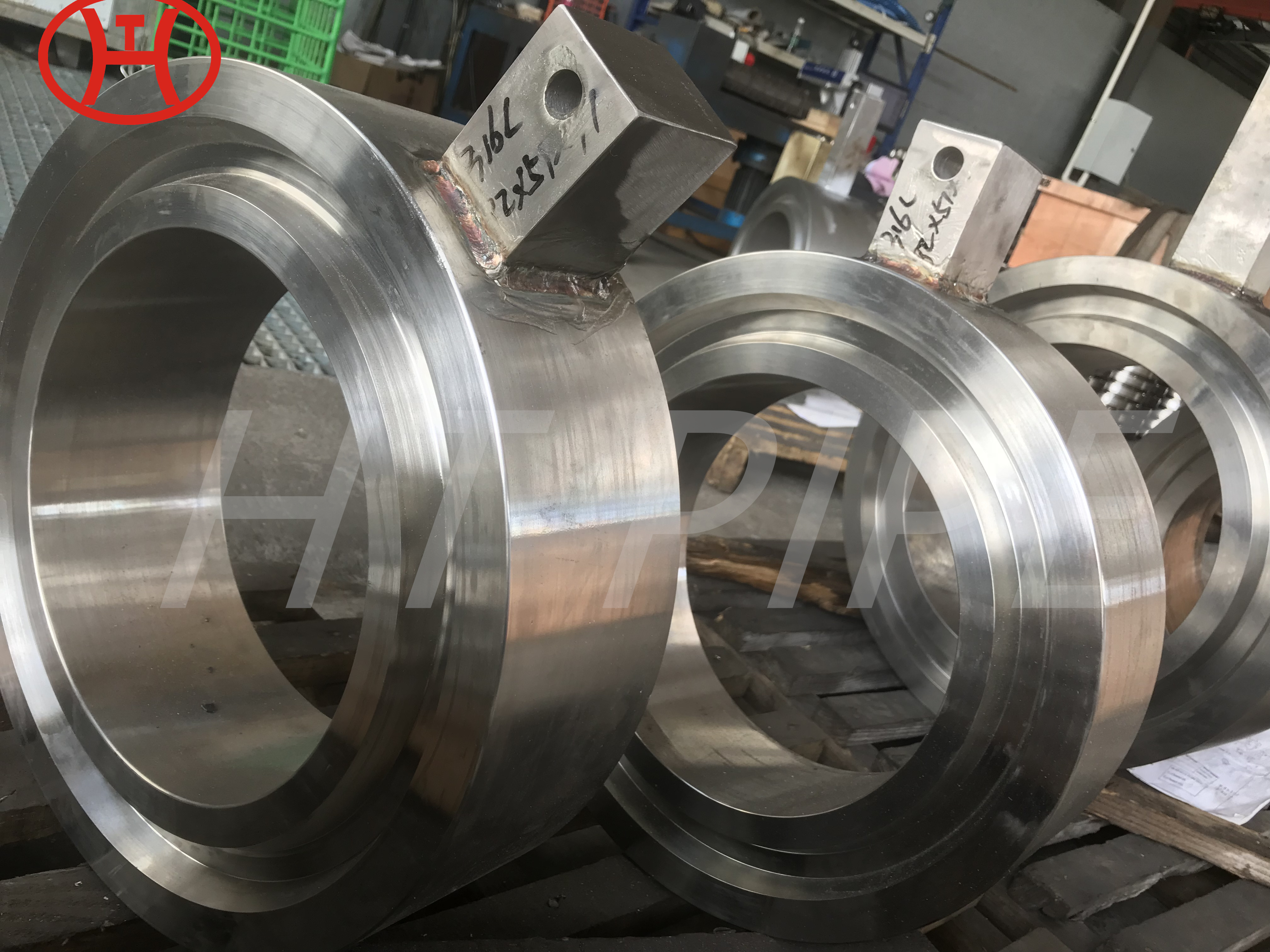

UNS NO8904 stainless steel is non-magnetic, and offers excellent formability, toughness and weldability. TP904L Stainless Steel Welded Pipe contains high amounts of expensive ingredients, such as molybdenum and nickel. Today, most of the applications that employ UNS NO8904 tube are replaced by low-cost duplex stainless steel 2205. The addition of copper to this grade gives ASTM A213 SS TP904L Tube corrosion resistant properties superior to the conventional chrome nickel stainless steels, in particular to sulphuric, phosphoric and acetic acids.

However, there is limited use with hydrochloric acids. UNS N08904 Tube also has a high resistance to pitting in chloride solutions, a high resistance to both crevice and stress corrosion cracking. Alloy 904L performs better than other austenitic stainless steels due to the higher alloying of nickel and molybdenum. Our offered ranges of SS 904L Pipes & Tubes are today seen greatly used in many industrial applications. Some applications are heat exchangers, condensers, piping systems, pulp & paper industry, petrochemicals, pharmaceuticals, specialty chemicals, chemical industry, building, power generation, gas processing, oil processing, constructions, seawater applications, and buildings, etc.

There are many properties found in this UNS NO8904 pipe. SS DIN 1.4539 Pipe is namely tensile strength, yielding strength, weldability, rugged construction, toughness, the anti-corrosive body; withstand high-temperature application, holds greater pressure, good surface finishes, long functionality, etc. The 904L Stainless Steel Pipe is non-magnetic in all conditions and has excellent formability and weldability. The austenitic structure also gives this grade excellent toughness, even down to cryogenic temperatures.

904L Pipe Specifications

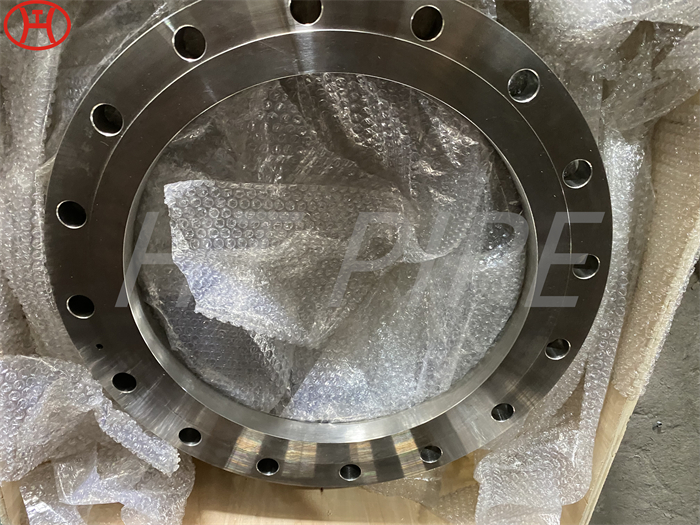

| Sizes | 3/8″ to 24″ NPS Seamless & Upto 64″ in Welded |

|---|---|

| Wall Thickness | Sch 5/5S to Sch 160/XXS |

| Length | Single Random (5-7 Meters) / Double Random (11-13 Meters) |

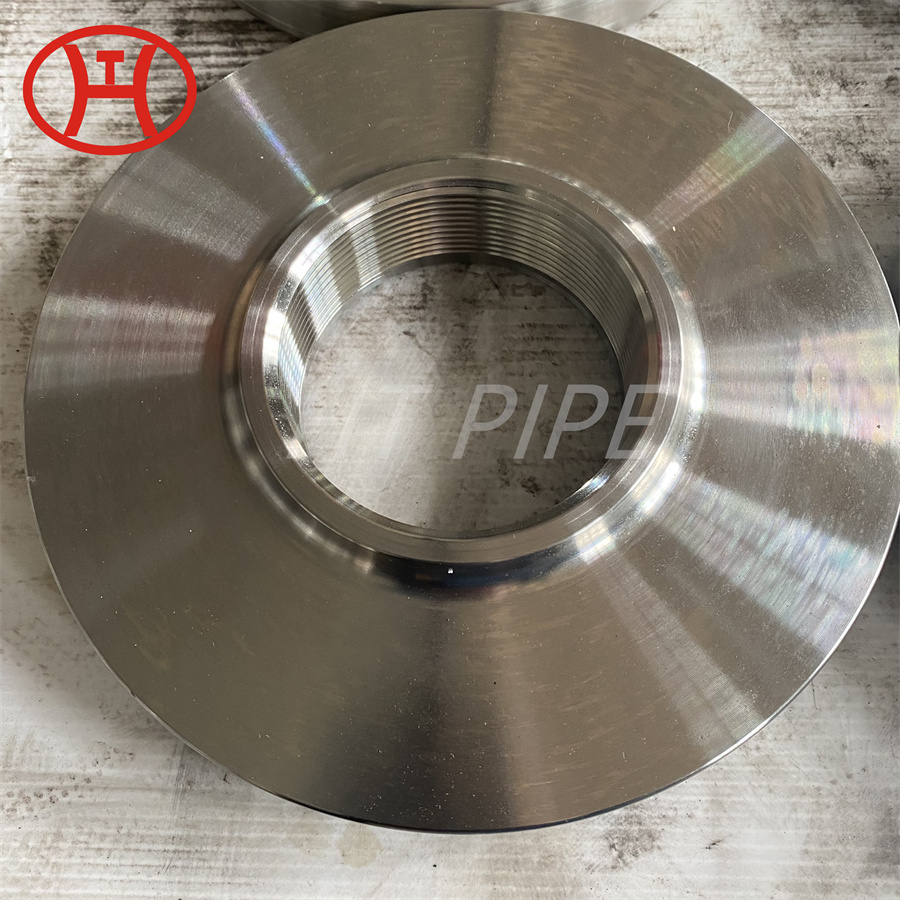

| Ends | Beveled End (BE), Plain Ends (PE), Threaded End (TE) |

| Construction | Seamless, Arc Welded (ERW), Fusion Welded (EFW) |

| Dimensions & Tolerances | ASME / ANSI B36.10M & B36.19M |

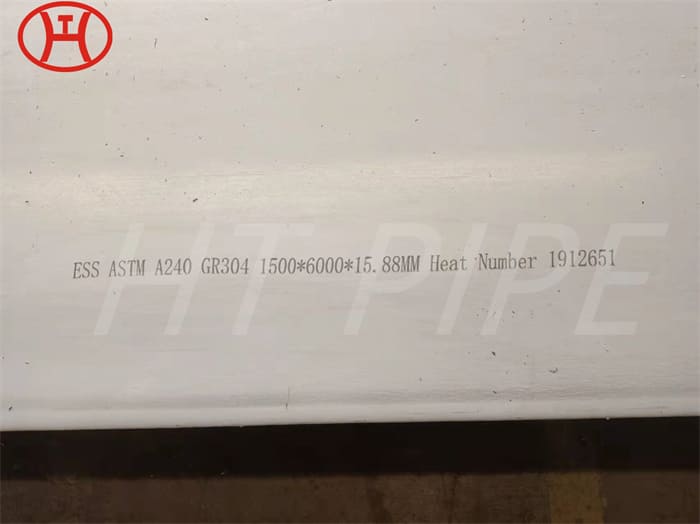

| Material Specifications | ASTM / ASME SA 312 TP 904L (UNS N08904), ASTM / ASME SA358 UNS NN08904 (TP 904L) |

| Origin | China, Korea, Japan, Sweden, Italy, France, Germany, UK & USA |