A182 F316L special flange sensitive industries such as food preparation

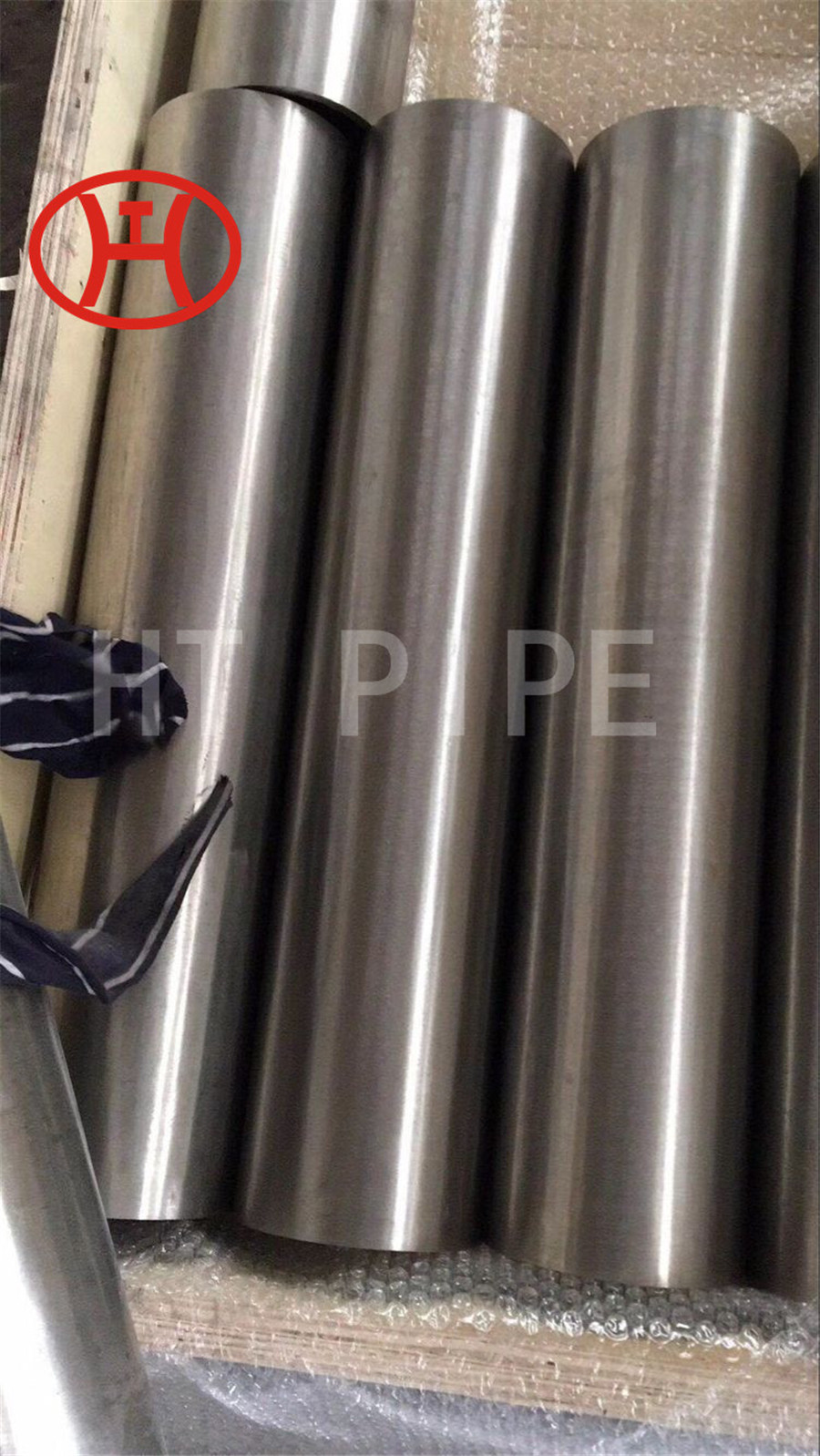

Where welding is required, the steel has the property of cracking as it cools. The high temperatures of the welding process cause what is known as “hot embrittlement” as the steel cools. This makes structures built with high carbon content steel more susceptible to damage due to the formation of cracks in areas where the metal is welded. 316l stainless steel alloy is used in a variety of applications as it is well suited to avoid weld corrosion. It can also withstand high temperatures and has a high melting point at about 2,500 degrees Fahrenheit or about 1,370 degrees Celsius. In addition to carbon, this alloy contains up to 2% manganese and up to 0.75% silicon.

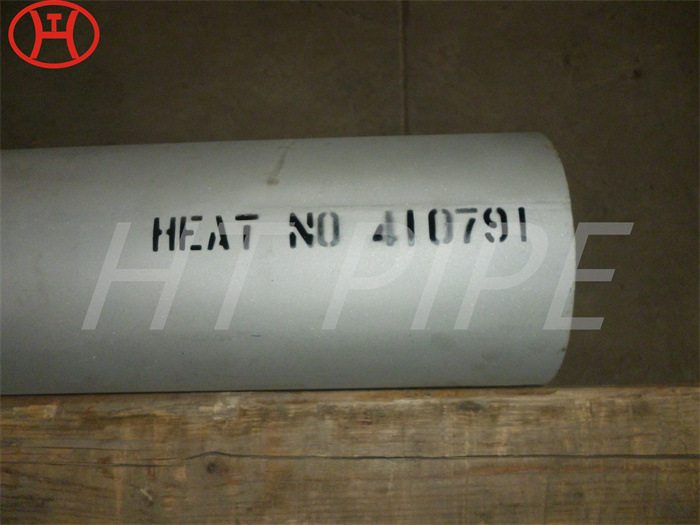

316L is a low carbon grade of 316. This grade is not affected by sensitization (grain boundary carbide precipitation). It is often used for heavy welded parts (approximately over 6mm). There is no discernible price difference between 316 and 316L stainless steel. Type 316 is an austenitic stainless steel with the addition of molybdenum to improve the alloy’s corrosion resistance. It is almost as popular commercially as 304 stainless steel.