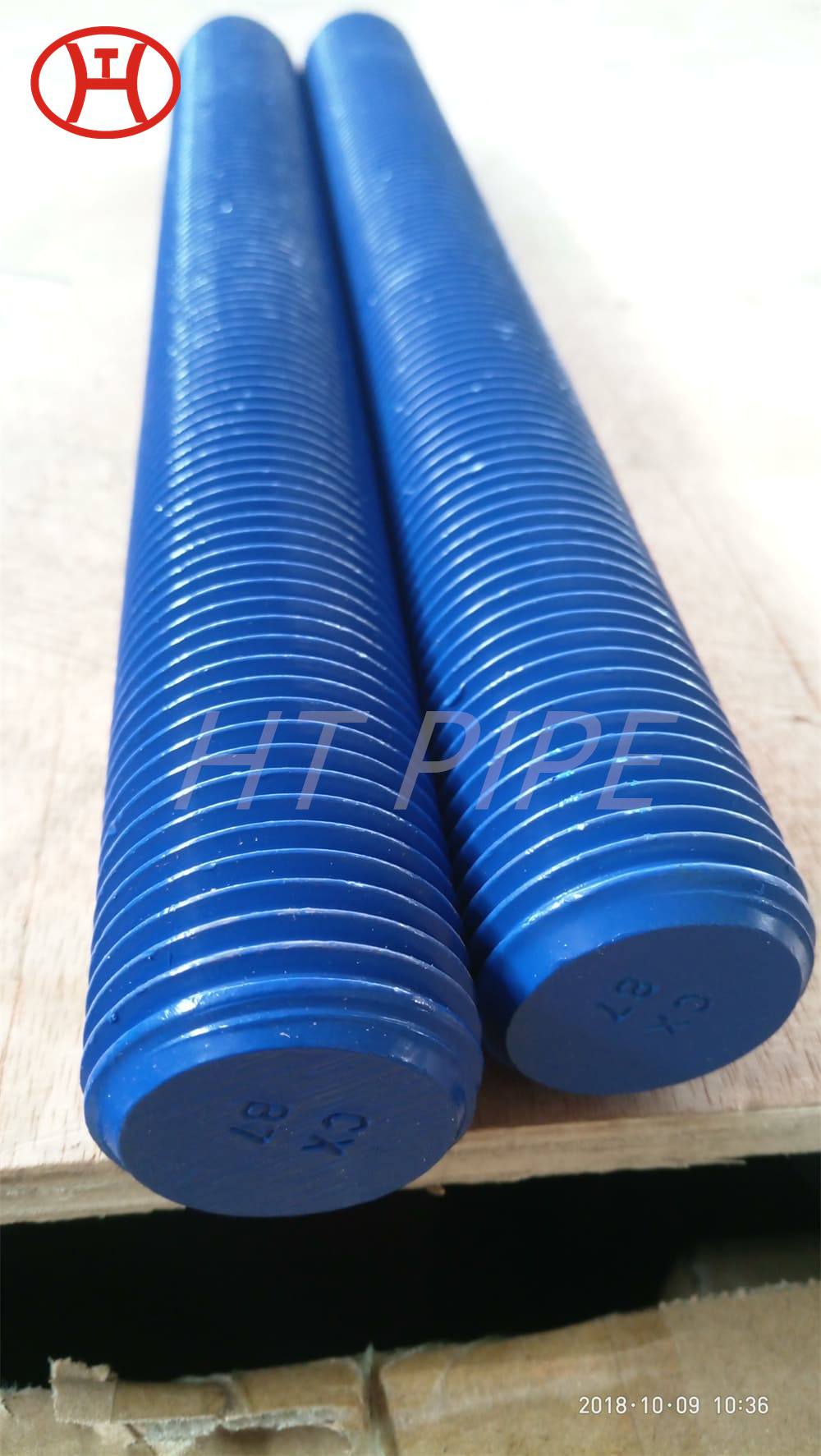

A182 F316L special flange the risk of contamination is much lower

The low carbon content of 316L provides an effective solution to a common engineering problem with 316 stainless steel. This small change in your application can have a big impact on your operating costs and quality assurance parameters as a business organization. Unlike other types of steel such as 304 and 306, the 316l stainless steel alloy can be used in a variety of applications where high corrosion resistance is required. For example, specialists in the chemical and pharmaceutical industries use it to make surgical tools and medical implants.

Compared to chromium-nickel austenitic stainless steels, 316L stainless steel has higher creep, rupture stress and tensile strength at elevated temperatures. The mechanical properties of this alloy are similar to Type 304, except that this grade is stronger at elevated temperatures. Type 316L is a low carbon version of Type 316 that minimizes carbide precipitation due to welding.