A479 astm a276 f53 s32750 2507 duplex round bar square bar flat bar

We are a manufacturer of Stainless Steel Round Bar, Formed Steel and Rebar, we supply bars such as 304, 304l, 316, 316l and 347. We are proud to have the largest share of stainless steel forming steel in the country.

Buy Large Or Small Quantity Super Duplex 2507 Round Bar Suppliers In China At Discounted Prices

Super Duplex Round Rods have excellent properties with good resistance to stress corrosion cracking, general corrosion, pitting and high strength, approximately twice that of austenitic stainless steels. Stainless Steel Super Duplex Grade 2507 Has Been Designed To Handle Highly Corrosive Conditions And Situations Were High Tensile Strength Is Required. The Possesses Excellent Mechanical Properties. Which Is Why, Often A Light Gauge Of Grade 2507 Material, Can Be Used To Achieve The Same Design & Strength Of A Thicker Walled Nickel Alloy End Product.

Thinner cross sections of the Super Duplex 2507 Round Bar results in weight savings, which in turn can dramatically reduce the overall cost of fabrication and the end product.The high content of elements like molybdenum, chromium and nitrogen in the Super Duplex 2507 Bar aid the material withstand general corrosion like pitting and crevice corrosion. Since Super Duplex 2507 Round Bar is also resistant to acids and chlorine compounds, its applications can be seen in marine environments, especially in salt water containing chlorine compounds. The ferritic portion of the duplex structure of the Super Duplex 2507 Round Bar alloy makes them resistant to stress corrosion cracking in warm chloride containing environments.

Super Duplex 2507 Round Bar has excellent resistance to chloride stress corrosion cracking. Our super duplex steel bars (WNR 1.4410) are being developed and engineered in our infrastructure to international quality standards to the highest quality standards. 2507 Super Duplex Stainless Steel is highly resistant to chloride pitting, stress, crevice and general corrosion. Stainless Steel Super Duplex Grade 2507 Bar tolerates organic and inorganic acids well. All of these elastic properties make Super Duplex 2507 Round Bars useful in harsh environments and are commonly used in chemical and petrochemical engineering, paper facilities, and marine environments. Additionally, the 2507 Duplex Stainless Steel Bar is resistant to chloride related stress corrosion cracking, to corrosion fatigue, to erosion corrosion, to general corrosion in acids. Stainless steel grade 2507 alloy has good weldability, Low rate of thermal expansion, Good workability and very high mechanical strength. Although the Super Duplex 2507 Rods has a high tensile strength and good corrosion resistance, the applications of the alloy should be limited to temperatures below 600° F or 316° C. Extended exposure of the Super Duplex 2507 Castings at elevated temperature can result in a reduction of both the toughness and corrosion resistance of alloy 2507.

| Standard | EN, DIN, JIS, BS, AISI, API, ASTM, ASME Round Bars |

|---|---|

| Specification | ASTM A276, A479 / ASME SA276, SA479 |

| 2507 Duplex Stainless Steel Round bars special price for | Dubai, UAE, Singapore & Malaysia clients. |

| 2507 Duplex Stainless Steel Round bars size | Diameter: 3mm – 450mm DIA |

| Length | 3 to 6 meter, Custom Cut Lengths |

| 2507 Duplex Stainless Steel Angle bar size | 3mm* 20mm* 20mm~12mm* 100mm* 100mm |

| 2507 Duplex Stainless Steel Square bar size | 4mm*4mm~100mm*100mm |

| 2507 Duplex Stainless Steel Flat bar size | Thickness: 2mm~100mm |

| Width: 10mm~500mm | |

| 2507 Duplex Stainless Steel Hex Bar size | 2mm~100mm |

| Surface |

|

| 2507 Duplex Stainless Steel Round Bar Standard Dimensions | Diameter / Height: |

| 2507 Duplex Stainless Steel Billet Size | 1/2″ to 495mm Diameter |

| 2507 Duplex Stainless Steel Rectangles Size | 33mm x 30mm to 295mm x 1066mm |

| Finish | Bright Polished, Black, Polish, Rough Turned, Grinding, Centreless Ground, NO.4 Finish, Matt Finish & BA Finish |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Condition | Annealed round bar, Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished, Sheared & Edged, Rolled Flat |

| Technique | 2507 Duplex Stainless Steel Cold Rolled, Hot Rolled,Forged Round Bar, Cold Drawn, Rod |

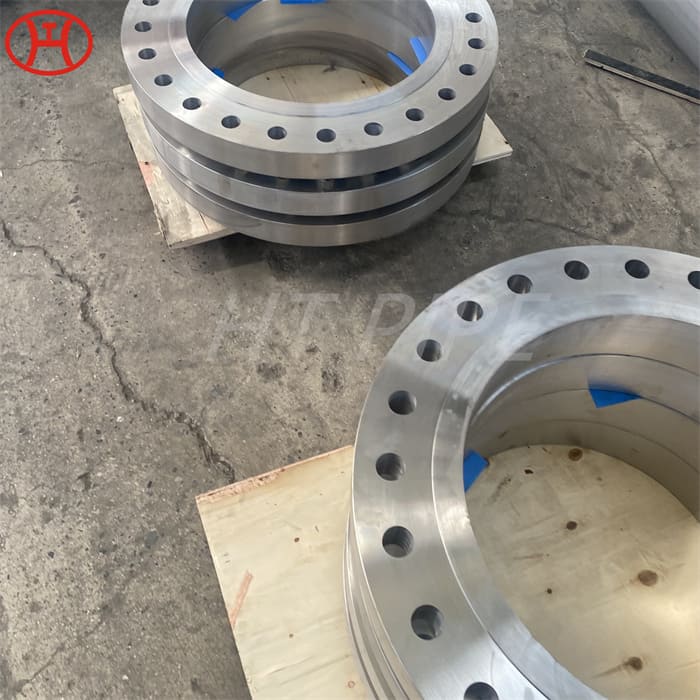

| Form | Rod, Round, Channel Bar, T-Bar, Flat Bar, Precision Ground Bar, Blocks, Square, Rings, Round Rod, Triangle, Hollow, Rectangle, Threaded, Hex (A/F), Profiles, Half Round Bar, Ingot, Billet, I/H Bar, Forging etc. |

| Manufacturing Process |

|

| Heat Treatment |

|

| Quality & Inspection |

|

| Features |

|

| Tolerances | according to EN 10278 – ISO 286-2 |

| Certificates | EN 10204 / 3.1 |

| Our 2507 Duplex Stainless Steel round bar conforms to NACE MR0175/ISO 15156 | |