acero duplex placa lamina bobina 2507 x2crnimon22 5 3

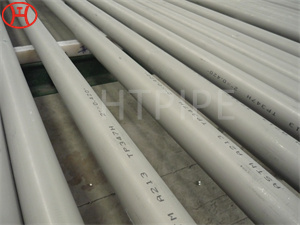

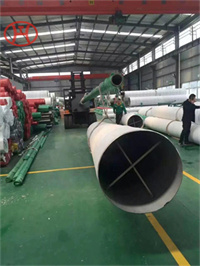

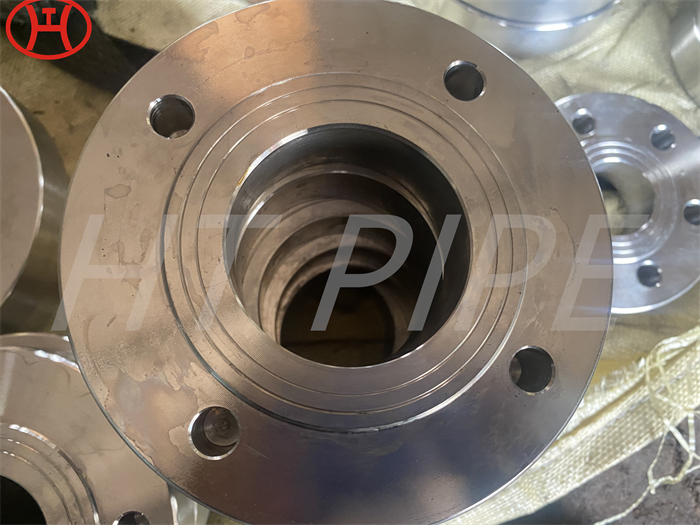

Super Duplex UNS S32750 is the most common Super Duplex grade on the market. UNS S32750 is a duplex stainless steel designed for use in corrosive chlorine-containing environments. It has very good localized corrosion and stress corrosion cracking resistance and high mechanical strength. Widely used in oil and gas, hydropower, pressure vessels, pulp and paper, structural parts and chemical tankers.

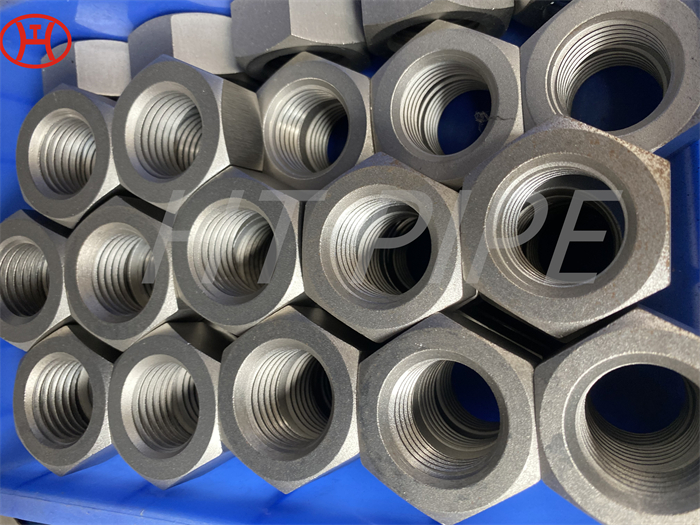

The term “super duplex stainless steel” was first used in the 1980s to refer to high alloy, high performance duplex steels with pitting resistance equivalents greater than 40 (based on Cr% + 3.3Mo% + 16N%). With its high content of chromium, super duplex steels have excellent resistance to acids, acid chlorides, caustic solutions and other environments in the chemical/petrochemical, pulp and paper industries, often replacing 300 series stainless steel, high nickel super duplex Austenitic steels and nickel-based alloys.

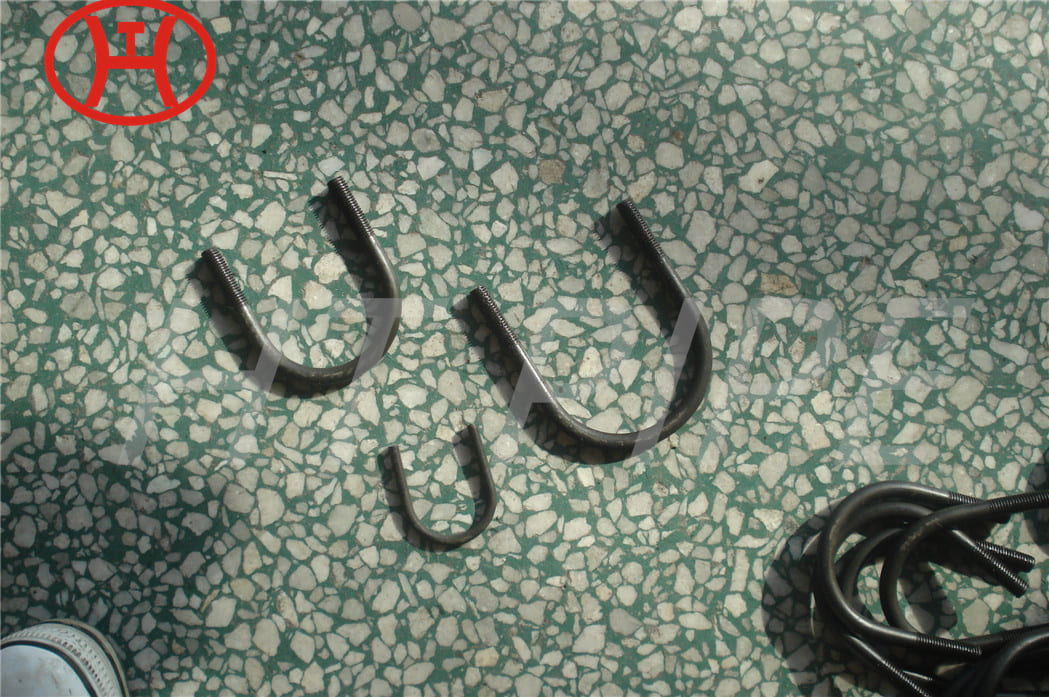

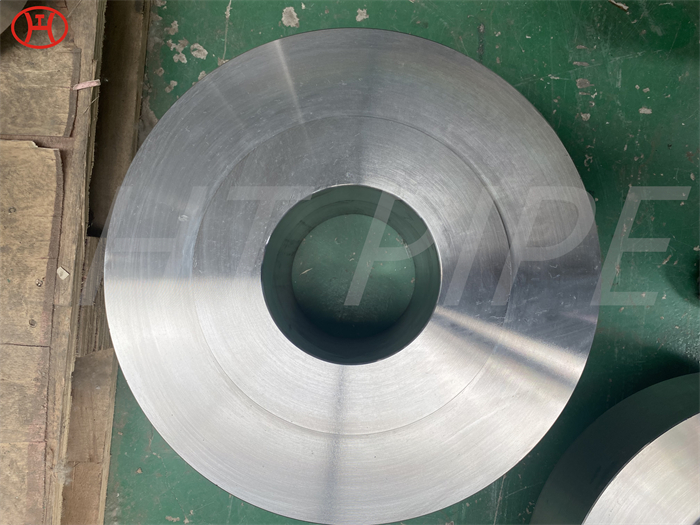

The material of AISI S32750 plate has increased tensile strength and yield strength. The super duplex steel S32750 sheet has a higher molybdenum and chromium content, and the super duplex steel UNS S32750 sheet has good ductility and toughness. Super Duplex Steel S32750 Coil has good corrosion resistance compared to Duplex Steel.

ASTM A240 is a specification covering various grades of chromium-nickel stainless steel components such as plate, sheet, and strip. In this case, the code contains ASME SA 240 S32750 grades and their chemical and mechanical performance requirements, making components produced to this code suitable not only for general applications, but also for pressure vessels.