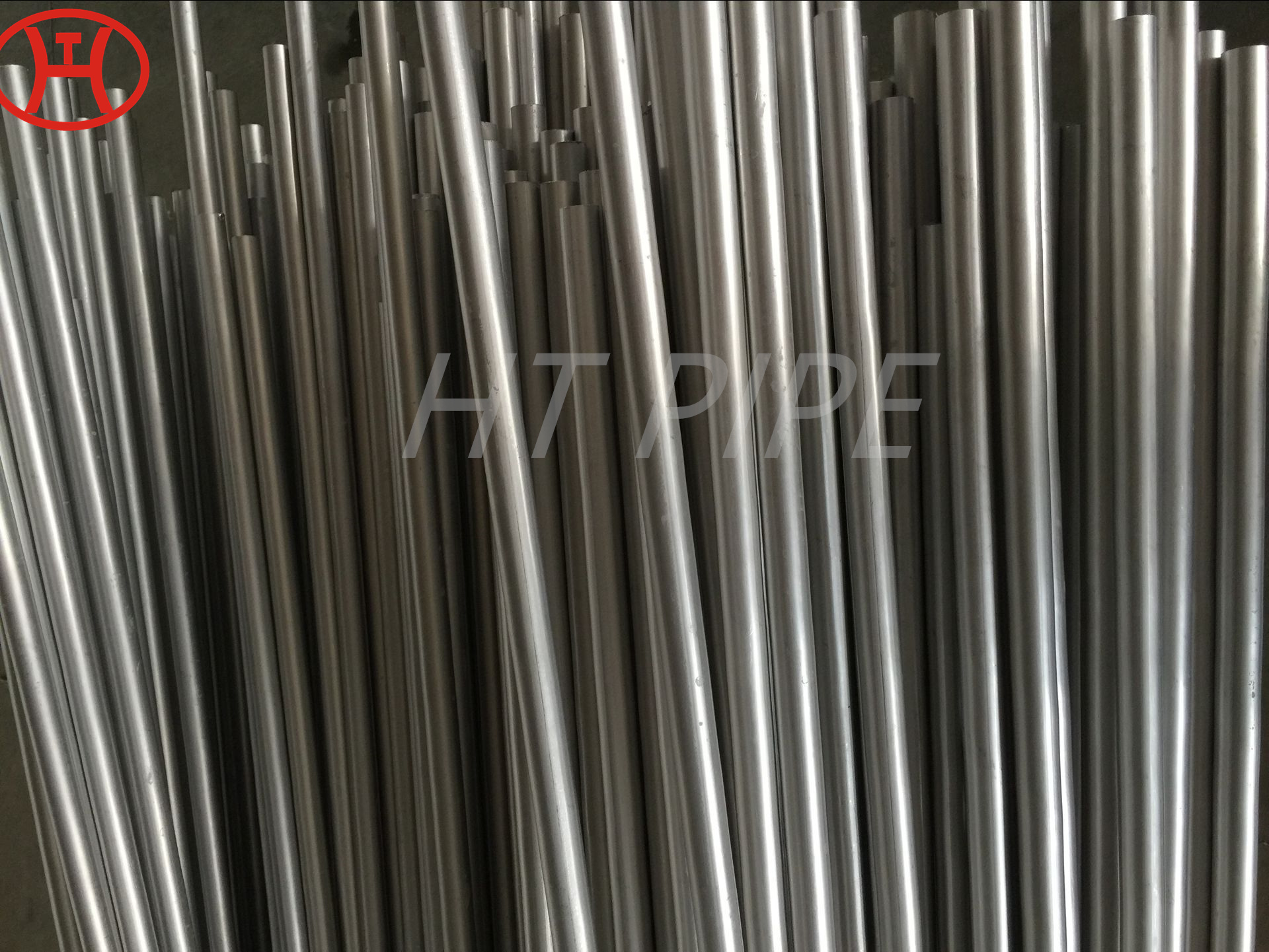

AISI 310s stainless steel seamless pipe

These low-carbon pipes, however, suffers from yield-point runout. The SA 312 TP304 Square Pipe can be easily installed in difficult areas in houses and buildings.

ASME SA 312 TP 310 ERW Pipe & Austenitic Stainless Steel 310 Welded Pipe manufatcurer in China

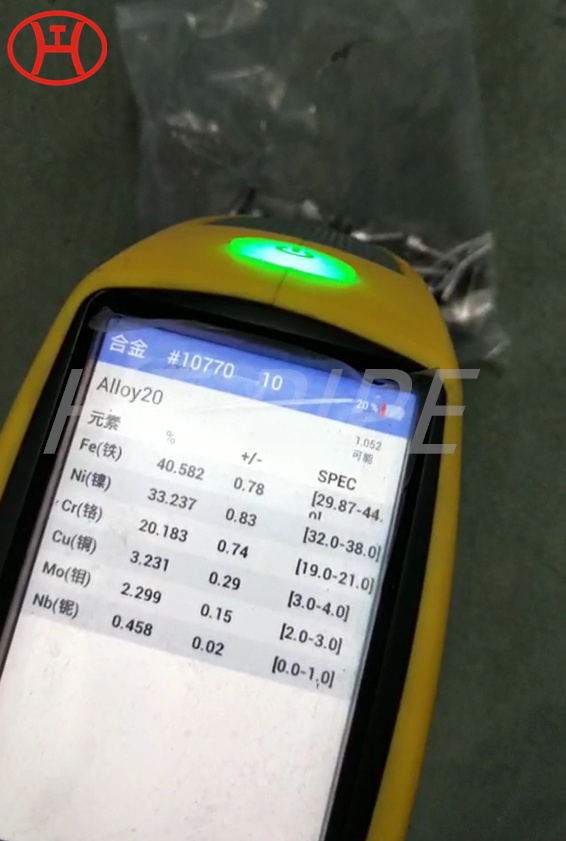

SS TP310 – 310S Seamless Tubing has a chemical composition of Manganese 2.00 max, Phosphorus 0.045 max, Carbon 0.25 max, Chromium 24.00 – 26.00, Silicon 1.50 max, Nickel 19.00 – 22.00 and Sulfur 0.030 max. UNS S31000 pipe is an austenitic heat-resistant alloy with excellent oxidation resistance. Mild cycling conditions to 2100°F. Its high chromium and nickel content provides comparable corrosion resistance, excellent oxidation resistance and a large portion of room temperature strength.

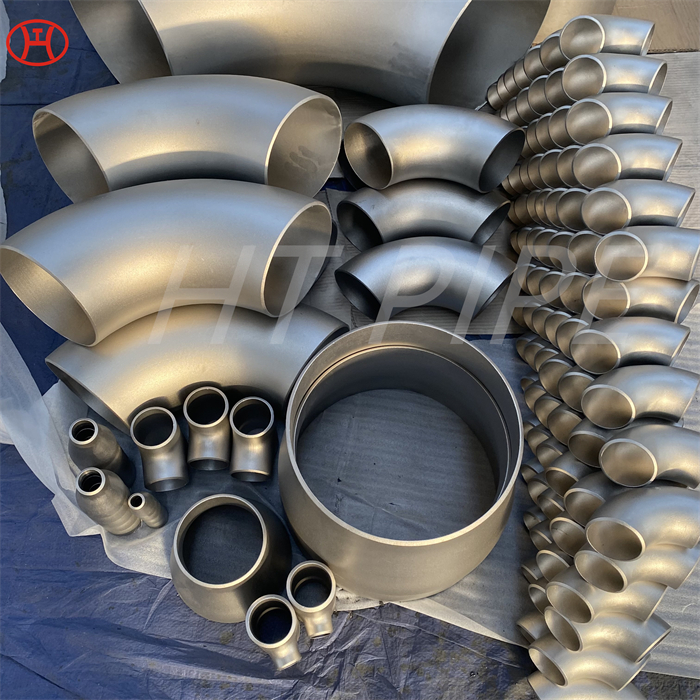

ASME SA 312 TP 310 pipes provides superior corrosion resistance properties against carburization, oxidation and other conditions. UNS S31000 pipe is fabricated to offer excellent performance in the elevated temperature conditions on the industrial level that need high resistance to carburization and thermal cycling corrosion. UNS S31000 pipe shows austenitic nature in the whole temperatures and doesn’t show embrittlement.The excellent strength and resistance to high temperature oxidation properties are purposeful in the commercial incinerators, kilns and food processing equipments.

ASTM A213 TP 310 tubes are used in the environmental, chemical processing and refining industries. Some examples of equipment composed of 310 stainless steel include incinerators, furnaces, burners, kilns, annealing and carburizing boxes, combustion chambers, salt pots, thermo wells, gas turbines, retorts, flairs and equipment to handle sulfite liquors.

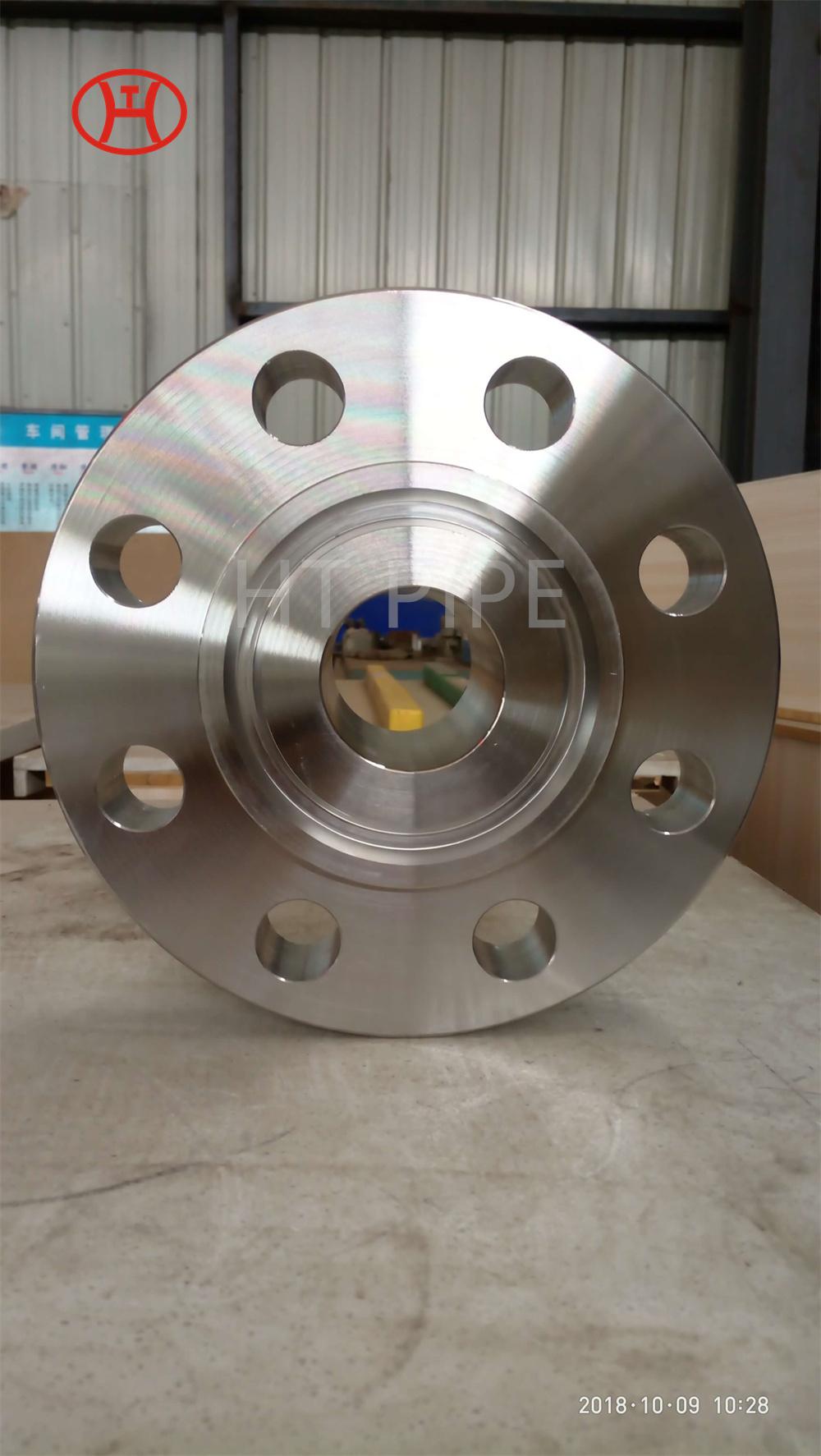

Material Specification of Stainless Steel 310 Seamless Pipe

oldest Grade stainless steel 310 seamless pipe Manufacturer, Wide size range in ss 310 tube, AISI 310 Welded Pipe find updated Price and specifications

| Specifications | ASTM A 312 ASME SA 312 / ASTM A 358 ASME SA 358 |

| Dimensions | ASTM, ASME and API |

| 310 ss pipe Types | Seamless, ERW, Welded, 100% X Ray Welded |

| Size OD (MM) | 6.00 to 610.00 |

| Size in NB | 1/8″TO 30″NB |

| length in MM | 6000, 3000, 2000, 12000, Or as Required |

| Wall Thickness | 0.5mm to 30mm |

| Specialized in | Large Diameter Size |

| Surface Finish | Mirror, Pickled & Annealed, Polish, 2B, No.4 |

| Value Added Services | Polishing, Beveling, Cutting, Threading |

| Schedule | Schedule20, Schedule30, Schedule40, STD, Schedule80, XS, Schedule60, Schedule80, Schedule120, Schedule140, Schedule160, XXS |

| Form | Square Pipes/Tubes, Round Pipes/Tubes, Rectangular Pipe/Tubes, “U” Shape, Pan Cake Coils, Coiled Tubes, Hydraulic Tubes |

| Test Reports & Third party Inspection | Mill Test Certificates, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, EN 10204 3.1, Chemical Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packaging | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or Custom packing |

| Domestic Network | Mumbai, Pune, Delhi, Chennai |