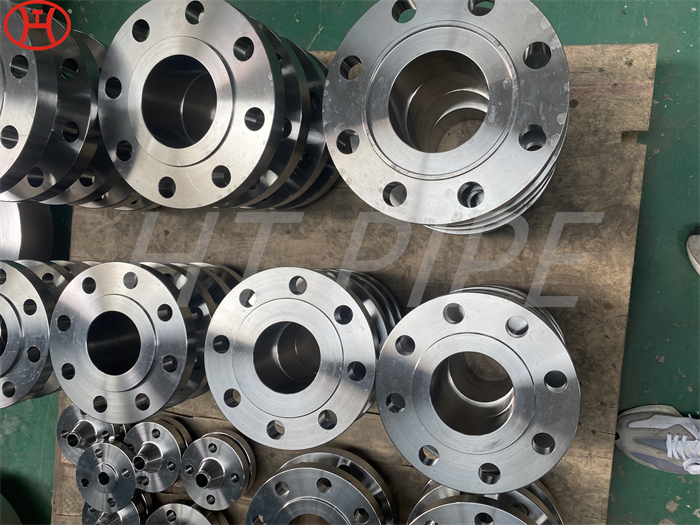

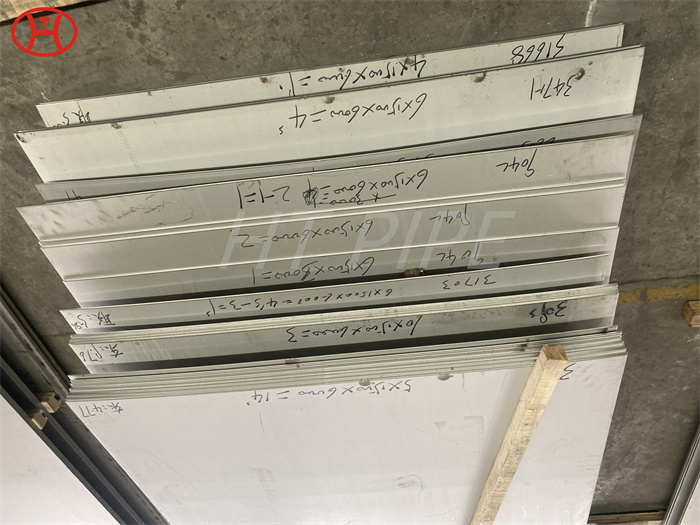

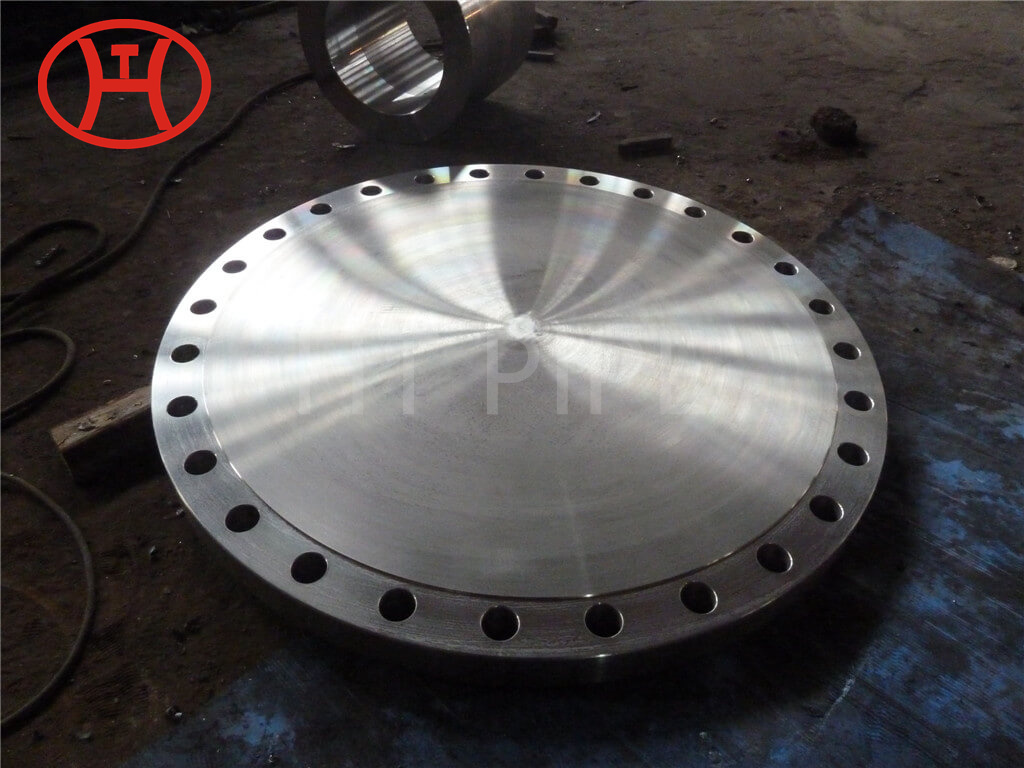

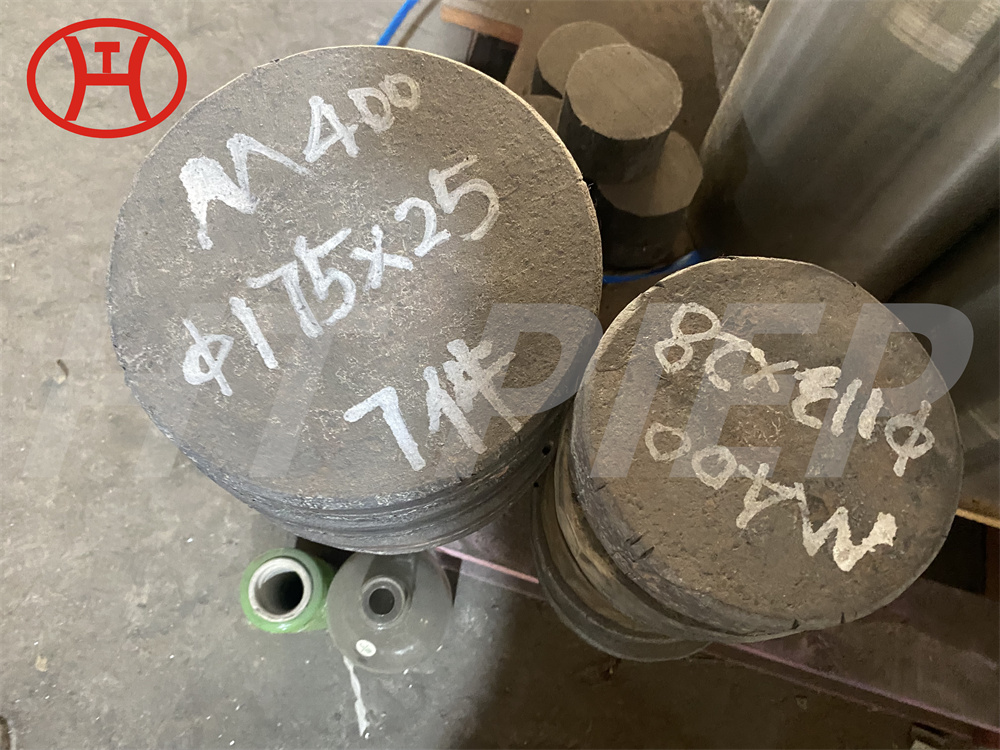

AL6XN N08367 Stainless Steel Plate Flange Steel AL6XN Ring Type Joint Flanges Stockholders

It is an austenitic stainless steel alloy with high nickel (24%), chromium (22%), molybdenum (6%), and nitrogen (0.18%) content and is commonly known as superaustenitic stainless steel (alloys such as 254 SMO (UNS?S31254) and 904L (UNS?N08904) also fall under the superaustenitic designation) while 2205 (UNS S32305/ S31803) and 2507 (UNS S32750) are duplex and super duplex stainless steel, respectively.

Due to the alloy¡¯s corrosion resistance and high strength, AL-6XN Stainless Steel Flange is a better choice than conventional duplex stainless alloy and more cost effective nickel-base alloys. Chromium, molybdenum, nickel and nitrogen all contribute to overall resistance to corrosion by various media. Chromium is the principal agent for conferring corrosion resistance in neutral or oxidizing environments. Chromium, molybdenum and nitrogen increase resistance to pitting corrosion. Nickel imparts the austenitic structure. Nickel and molybdenum both provide increased resistance to chloride stress corrosion cracking in reducing environments.AL-6XN is low carbon, nitrogen bearing super austenitic stainless steel. The alloy was designed to be a seawater resistant material and has been found to be resistant to a broad range of corrosive environments. Due to the alloy’s corrosion resistance and high strength, AL-6XN Stainless Steel Flange is a better choice than conventional duplex stainless alloy and more cost effective nickel-base alloys.