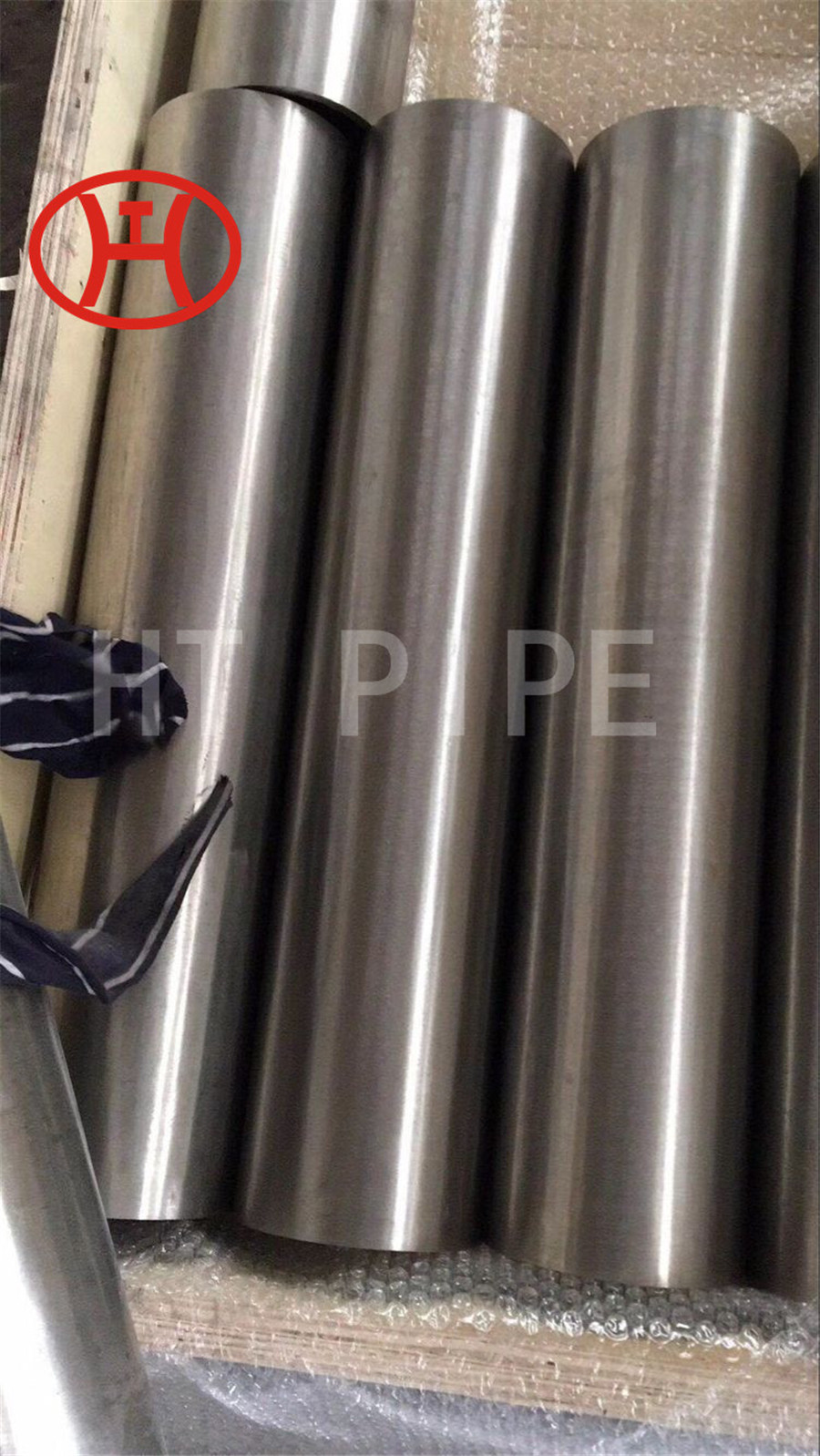

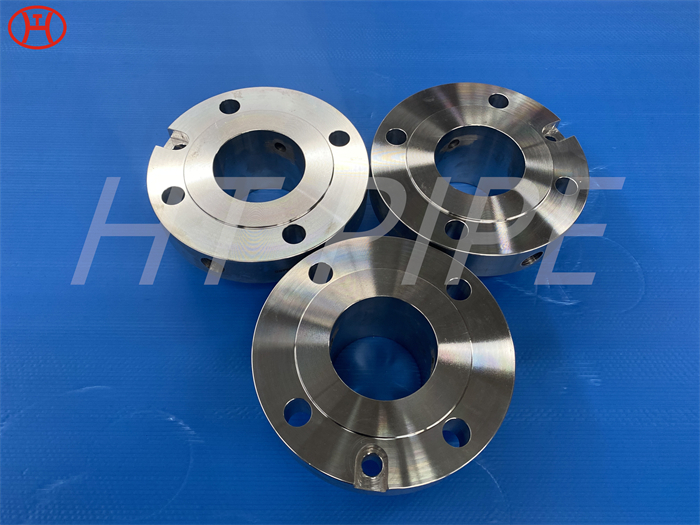

AL6XN prefabricated piping systems resistance to stress corrosion cracking

Chromium, molybdenum, nickel and nitrogen all contribute to overall resistance to corrosion by various media

AL-6XN is widely used because it is a 6% molybdenum super-austenitic alloy with strong resistance to chlorides that commonly cause localized corrosion in ketchup, barbecue sauce, sports drinks, buffer solutions and active pharmaceutical ingredients resistance. All methods, except oxyacetylene welding, have been successfully used for this alloy. While Type 316 stainless steel filler metal may be sufficient for some applications, it is best to use a higher alloy such as 625 or C-276 for best performance. Alloy AL6XN is an extremely strong nickel-molybdenum alloy with many beneficial properties, including practical immunity to stress corrosion cracking in NaCl environments.