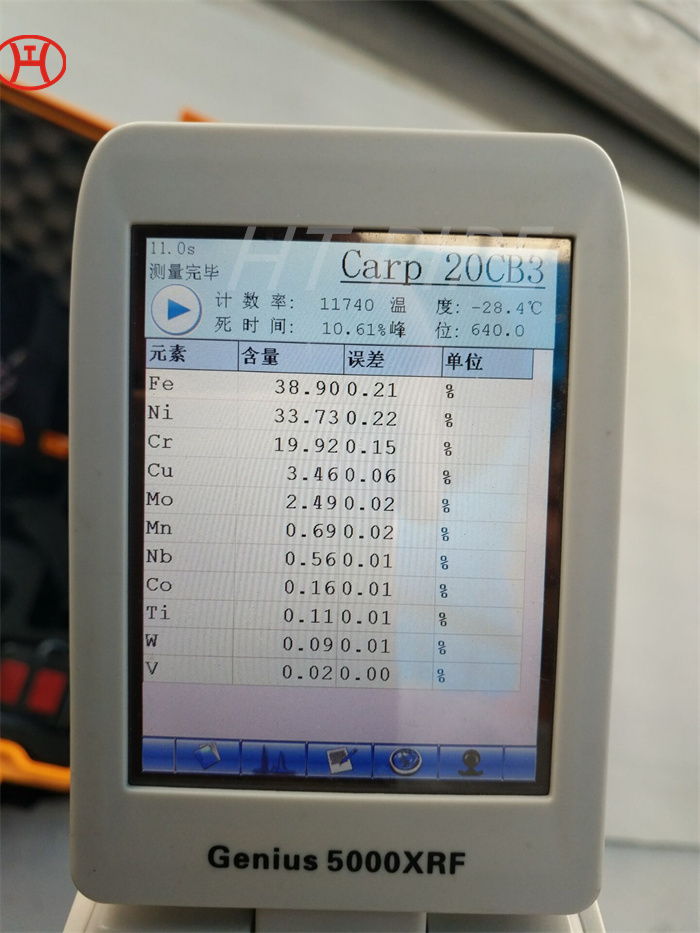

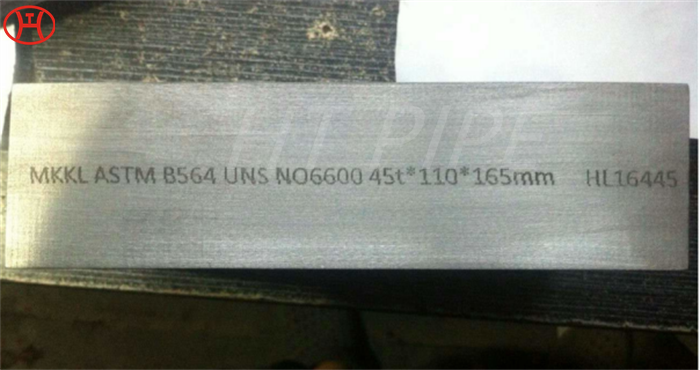

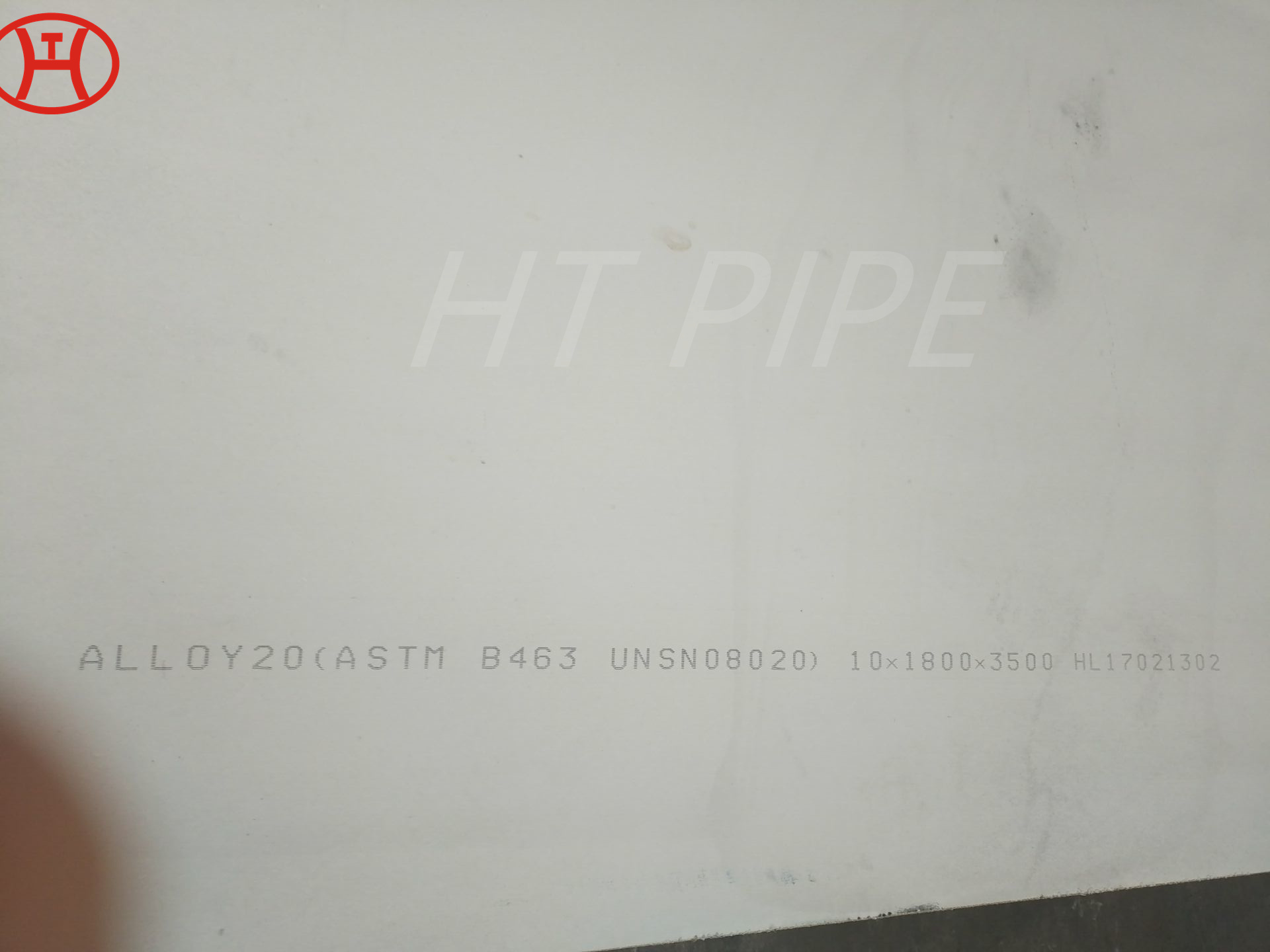

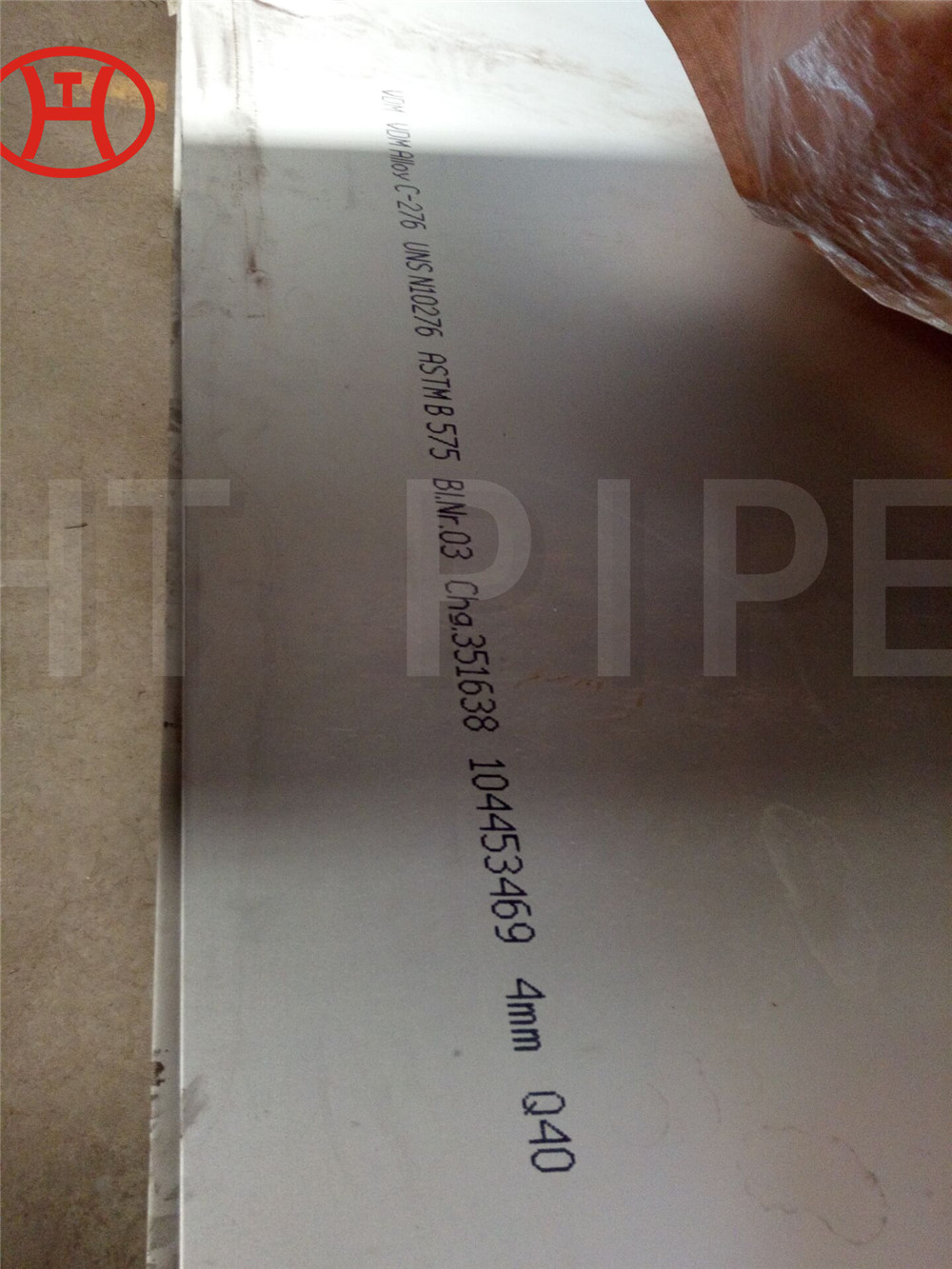

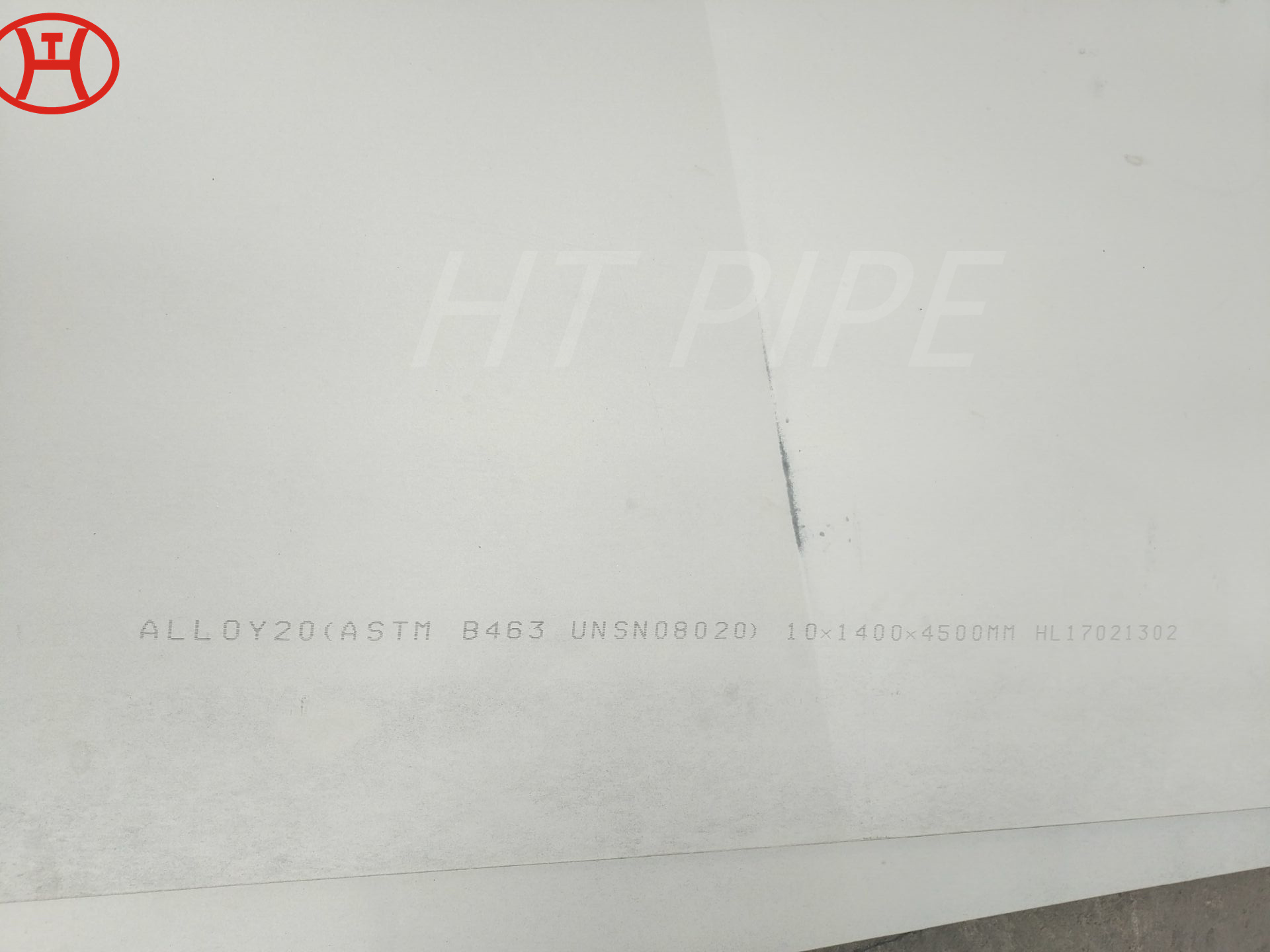

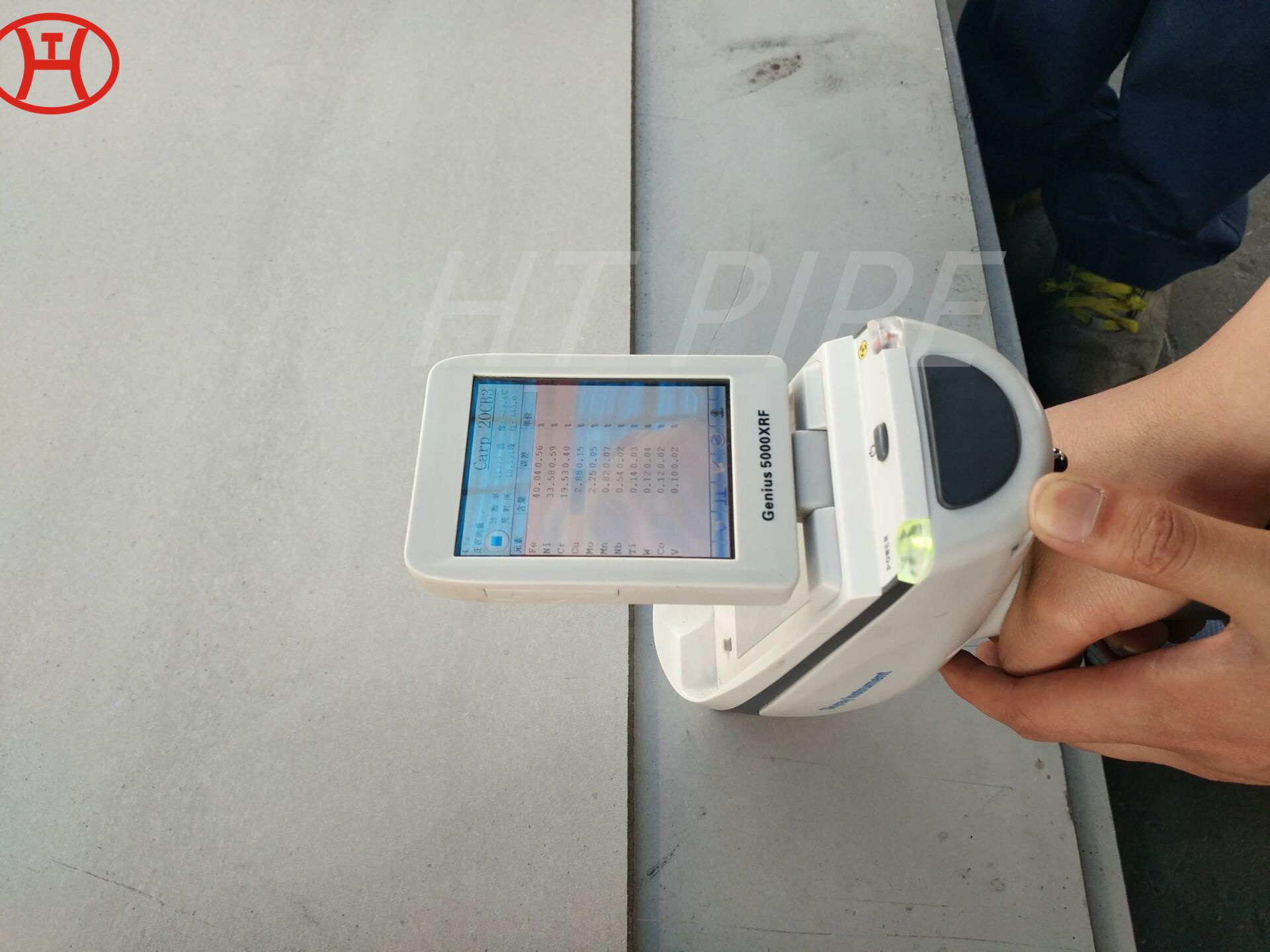

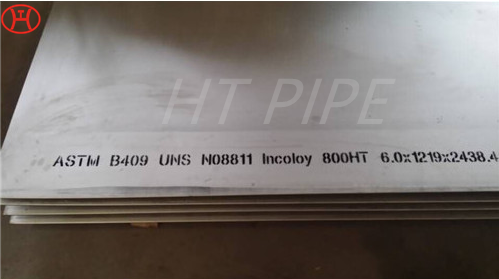

alloy 20 steel plate nickel alloy N08020 coil sheet strip PMI TESTING

ASTM B463 UNS N08020 Sheet can be formed by hot or cold working using conventional methods. Hot forged material should be heated between 2100¡ãF and 2250¡ãF, with the temperature carefully controlled to ensure that the material does not drop below 1800¡ãF prior to forging. After hot working, the material shall be heat annealed between 1725¡ãF and 1850¡ãF for a minimum of 30 minutes per inch of thickness and then water quenched.

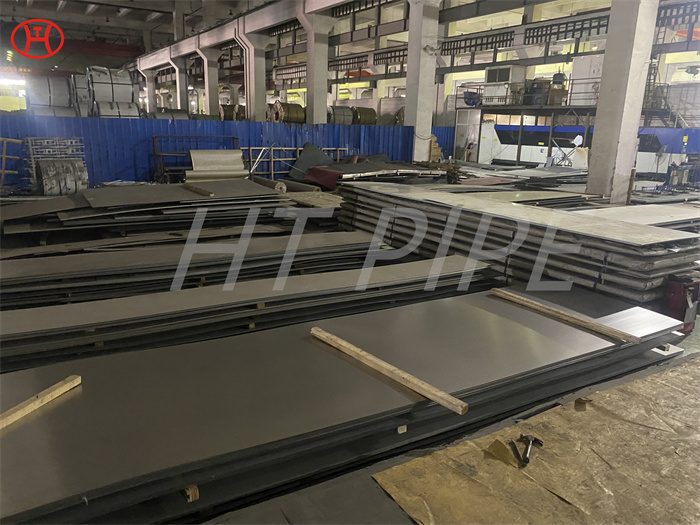

2.4660 alloy 20 pieces are widely used in petrochemical and oil refining, chemical processing, pharmaceutical, marine and food processing. Its end uses include agitators, storage tanks, pump and valve components, mixing tanks, fasteners, accessories and food processing equipment. According to ASME, its application is limited to temperatures up to 1000¡ãF. This grade of alloy steel has good corrosion and oxidation resistance, high strength and toughness, precise design with precise dimensions, easy installation, robustness, and longer service life. Mechanical properties and machinability, and have good weldability.