Alloy 317L UNS S31703 317 pipe spools

The higher molybdenum content of Alloy 317L assures superior general and localized corrosion resistance in most media when compared with 304/304L and 316/316L stainless steels.

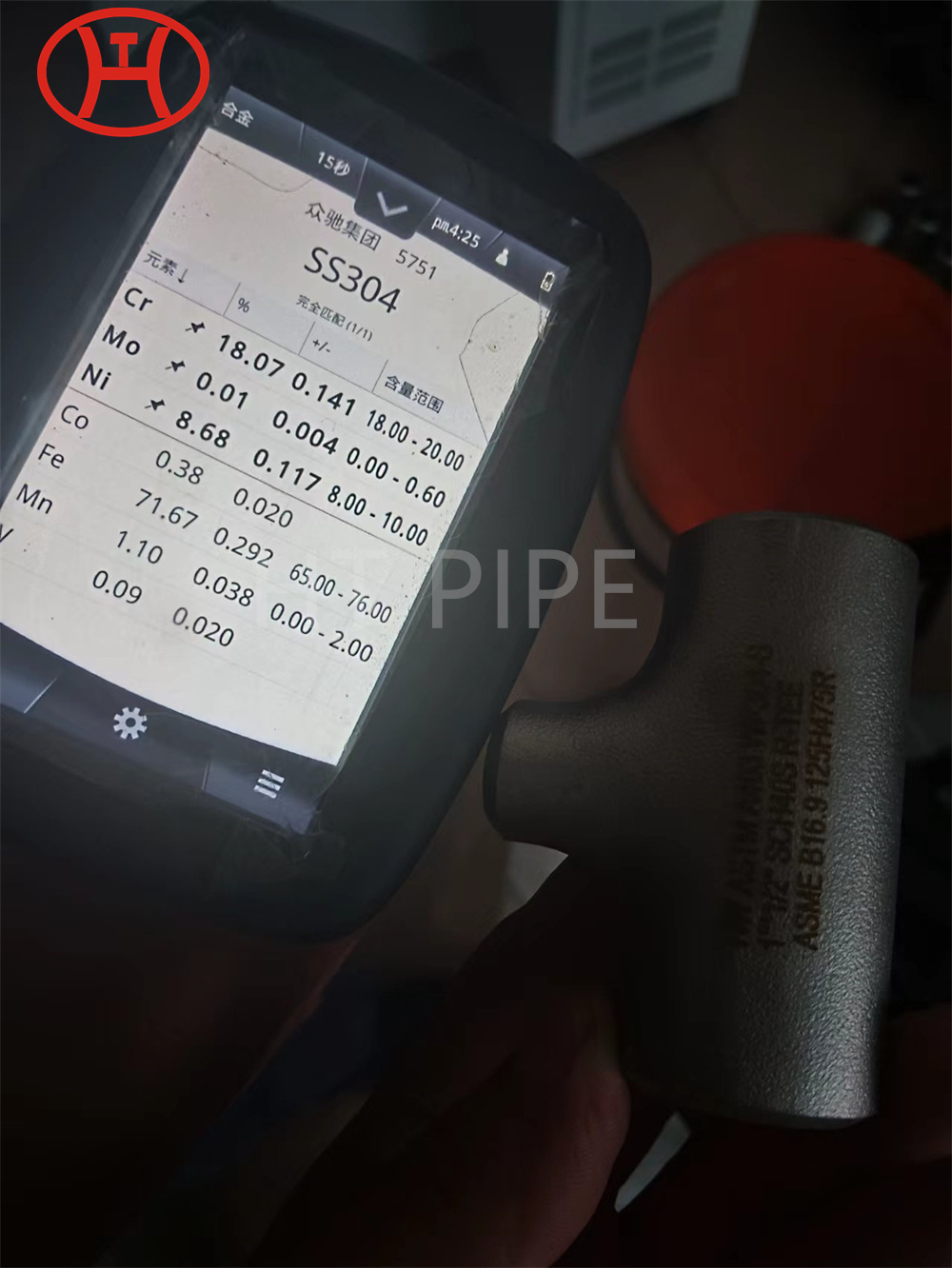

High levels of these elements ensure that the alloy has chloride pitting and general corrosion resistance superior to traditional 304/304L and 316/316L grades. Due to its low carbon content, 317L is also resistant to sensitization when welded and has higher creep, rupture stress and tensile strength at elevated temperatures. It is non-magnetic in the annealed state, but may become slightly magnetic after welding. 316 and 317 SS differ from 304 SS in that these higher numbered alloys have molybdenum added to their formulation – grade 316 contains about 2-3% molybdenum, while grade 317 contains more than 3% molybdenum.