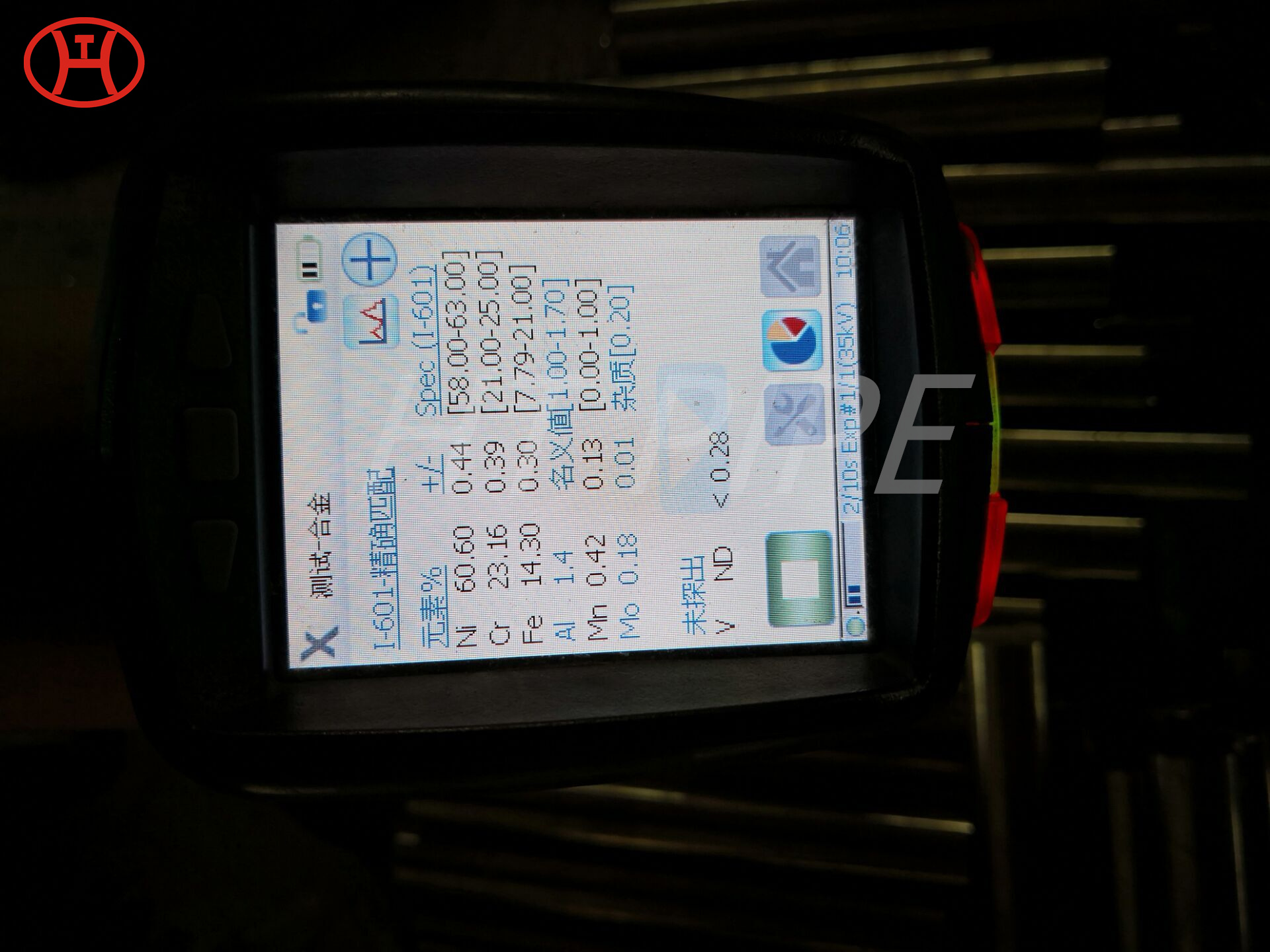

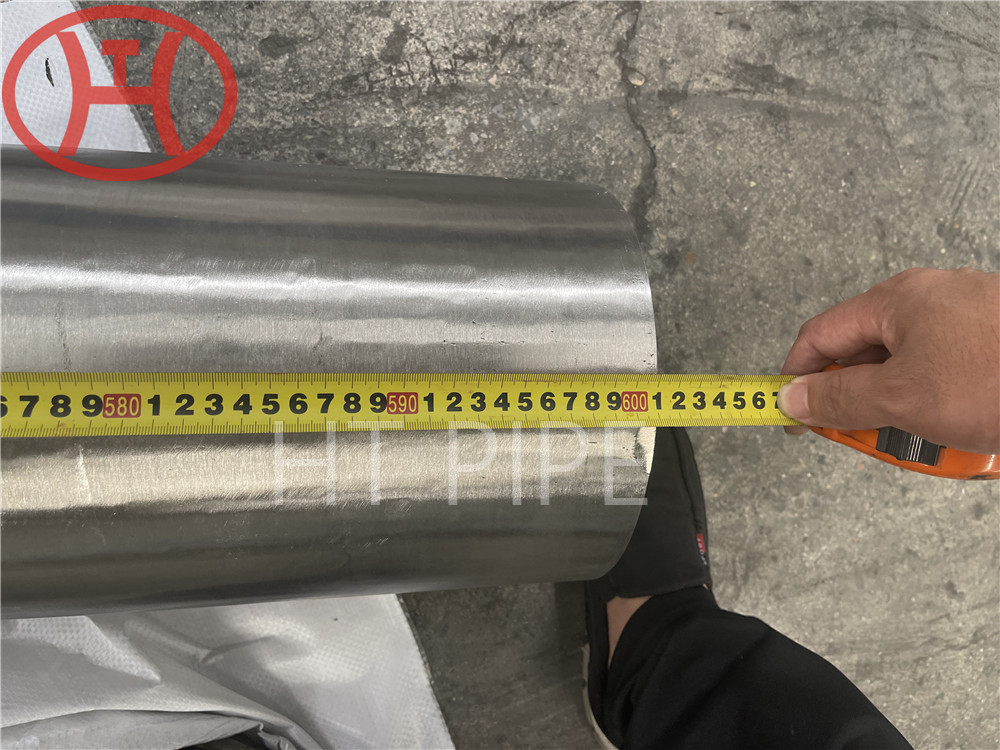

Alloy 601 round bar PMI testing

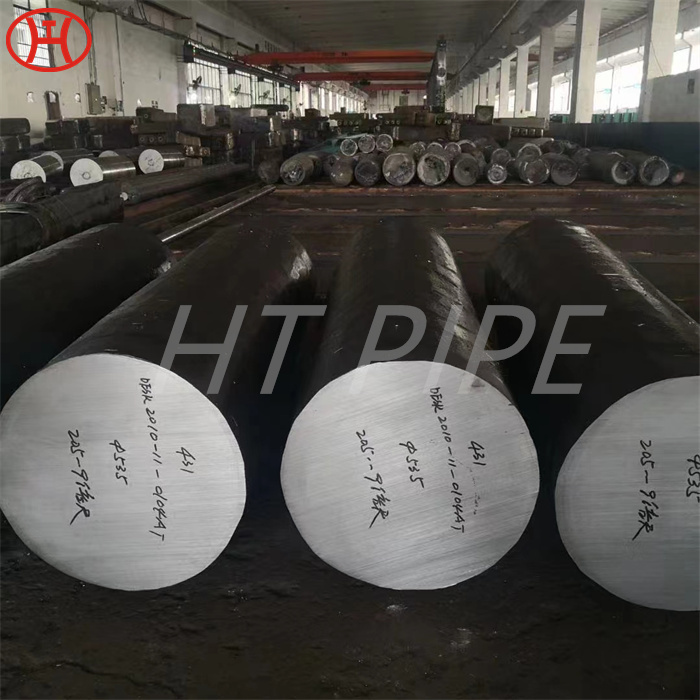

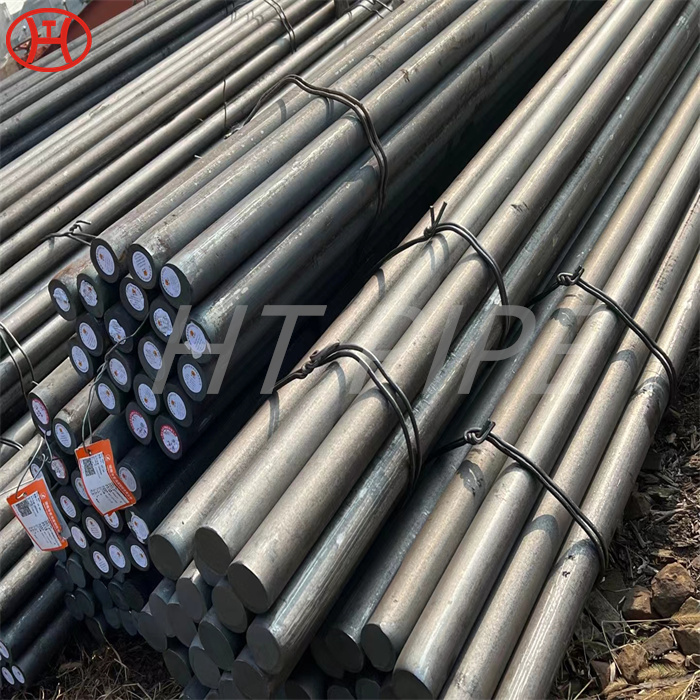

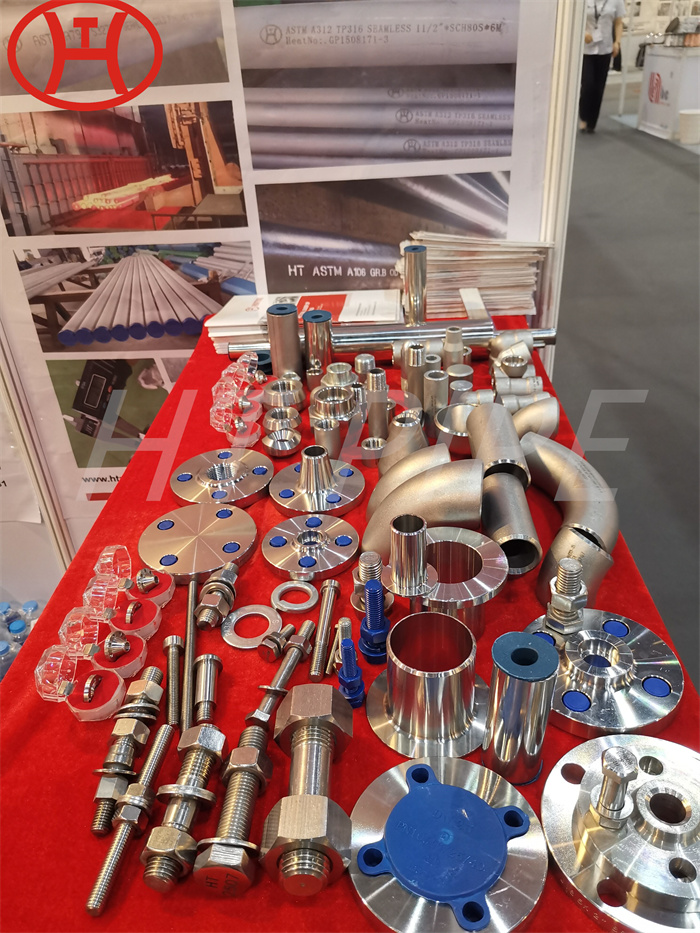

Inconel 601 is a nickel-chromium alloy with strong oxidation resistance at 2200¡ãF. Alloy 601 produces a tightly adherent scale that resists spalling even under severe thermal cycling. The alloy has good high temperature strength and retains its ductility after prolonged use. Alloy 601 has good resistance to hot corrosion under oxidizing conditions. Alloy 601 is not recommended for strongly reducing sulfur-containing environments.

Alloy 600 is a heat-resistant alloy due to its excellent resistance to hot gases and combustion products, as well as molten salt and molten metal corrosion above 550 ¡ãC (1022 ¡ãF), while exhibiting good mechanical short-circuit properties. time and long-term properties. Even under harsh conditions, such as cyclic heating and cooling, Alloy 601 maintains a tightly adhered oxide layer that is very resistant to spalling. Meanwhile, Nickel Alloy 601 bar, bar and wire is a nickel-chromium alloy with aluminum additions that provides high mechanical properties at elevated temperatures, as well as excellent resistance to oxidation, carburization and sulfidation. It is particularly resistant to scale removal in cyclic oxidation applications with high temperature changes.