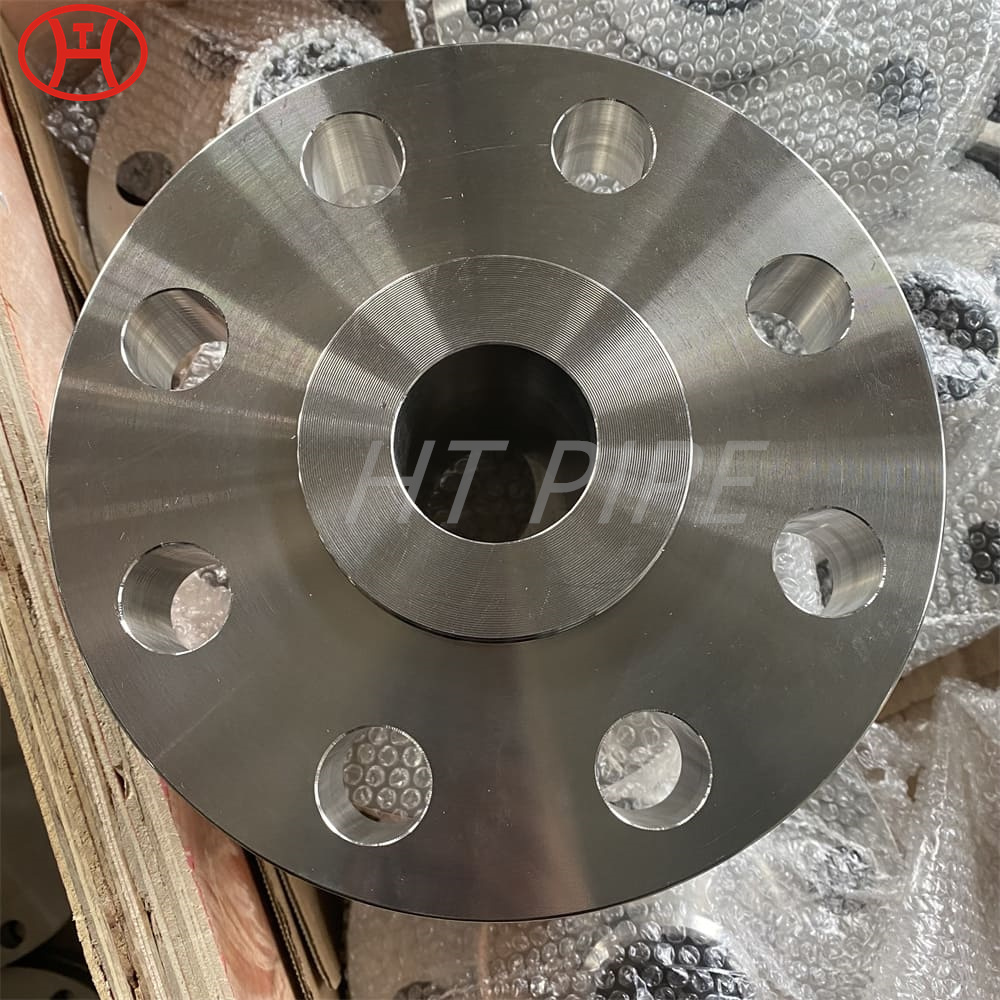

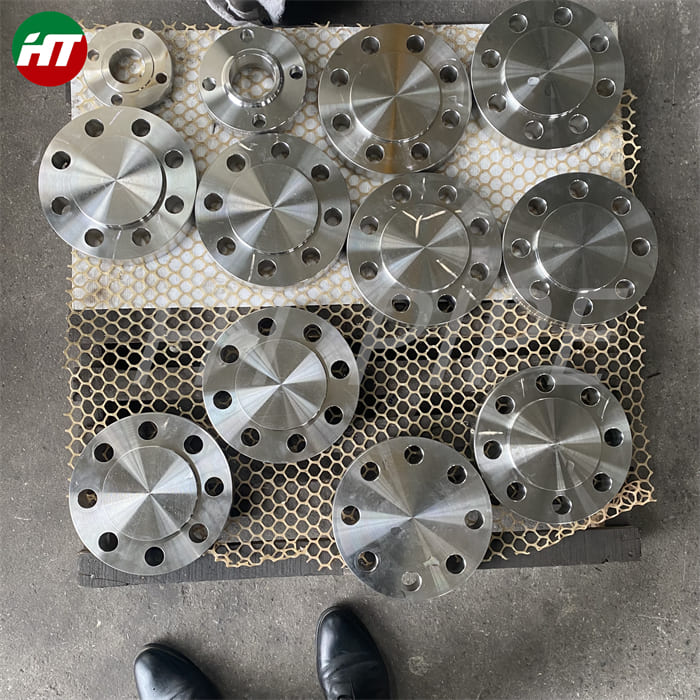

Alloy 625 RTJ Flange 625 Inconel Ring Type Joint Flanges Wholesaler

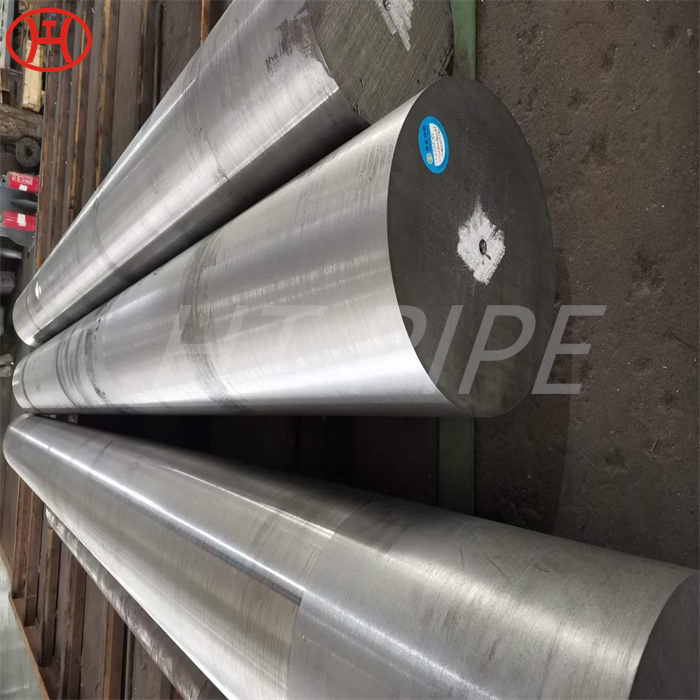

The minimum yield strength of the flanges is 517MPa and the minimum tensile strength is 930MPa. These are relatively high strength flanges compared to most stainless steel flanges. The high strength of the Inconel alloy 625 Slip on Flanges and the other types comes from the material composition. The material is made up of 58% nickel, 20% chromium, carbon, manganese, silicon, sulfur and 5% iron. The high nickel and chromium content make the flanges highly corrosion resistant.

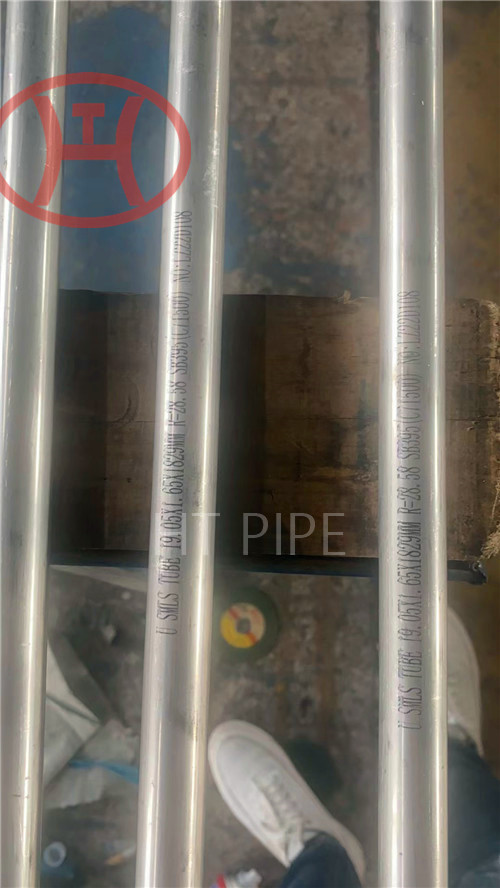

This is a primary reason for which threaded flanges are highly demanded across several industries. Threaded flanges are used in conjunction with pipes that have external threads, which means these flanges can be attached without welding. Are you looking for Manufacturer of 625 Inconel Lap Joint Flanges. On the other hand, a UNS N06625 Weld Neck Flange is often used for applications where high pressure is an important requirement. This is because these flanges not only transfer stress from the flange to the pipe but they also reduce the concentration of stress from the base of the hub. Blind flanges are commonly used for testing the flow of media i.e. gas or liquid through a pipe or vessel, in addition to being used to seal the end of either piping systems or pressure vessel openings. We are Din 2.4856 Forged Flanges Manufacturer. ASTM B564 Nickel 625 BLFR Flange permit for easy access to the pipe in a system in case work must be done inside the line.