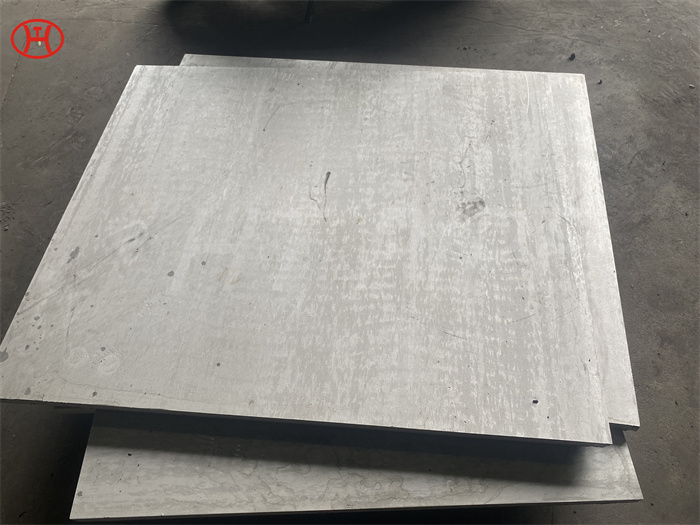

Alloy C276 UNS N10276 ASTM B575 plate

Machining of Hastelloy UNS N10276 polished plates is best done in the annealed condition. Since this particular alloy grade is prone to work hardening, only low cutting speeds are required.

Hastelloy C276 boards can be easily welded using the most traditional processes, including practices such as Plasma, GMAW (MIG/MAG), GTAW (TIG) and SMAW (MMA). In general, 2.4819 Hastelloy C276 Coil does not require post weld heat treatment. Hastelloy is a common nickel-molybdenum-chromium alloy. It is divided into different levels according to its inherited properties. One such grade is Hastelloy C276 plate, which is made by adding trace amounts of tungsten. It resists deterioration over a wide temperature range. Alloy C-276 (UNS N10276, W.Nr. 2.4819) is known for its corrosion resistance in a variety of corrosive media. The high molybdenum content imparts resistance to localized corrosion such as pitting.