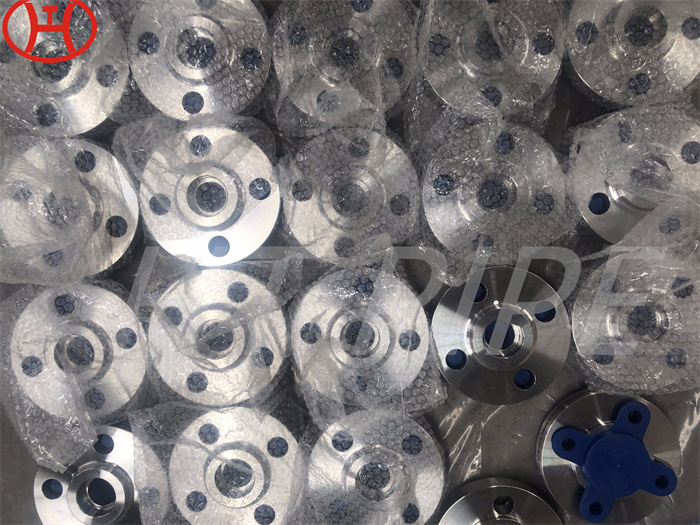

alloy flanges A182 F5 plate flange

For the F5 flange, the creep strength of the chromium-molybdenum low alloy mainly comes from two sources: the solid solution strengthening of the matrix ferrite by carbon, molybdenum and chromium and the precipitation hardening of the carbides.

ASTM A182 is the specification for flanges and F5 is the grade for alloy steel. ASTM A182 F5 flanges are available in nominal bore sizes from ?¡± to 36¡±. Alloy steel F5 flanges can vary in size according to ANSI, ASME and DIN standards. At the same time, the added chromium (Cr) in F5 not only increases wear resistance and corrosion resistance, but also improves the resistance to high temperature hydrogen corrosion and graphitization. Molybdenum (Mo) content acts as a grain refiner, increasing creep resistance and high temperature strength. It also improves pitting resistance in many environments.