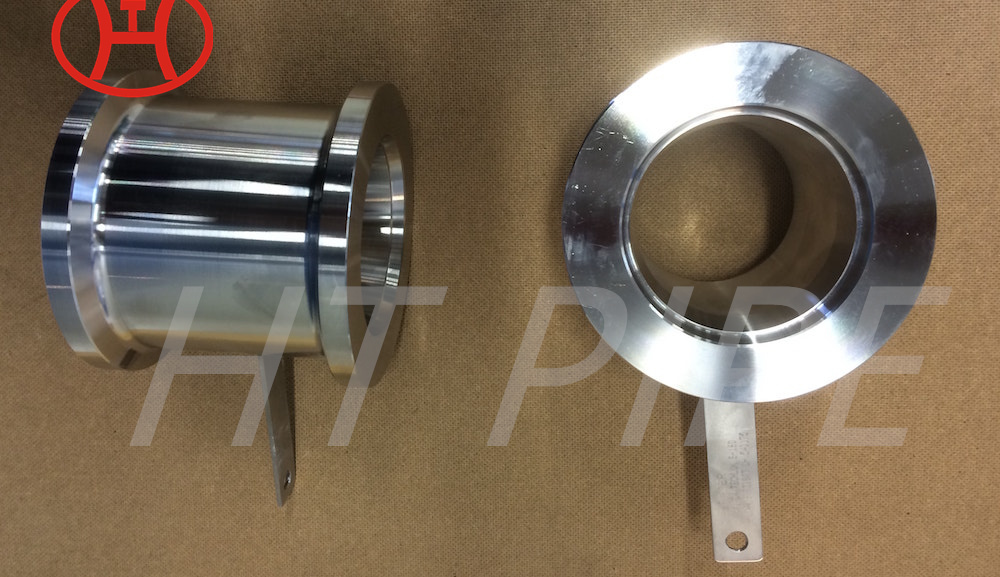

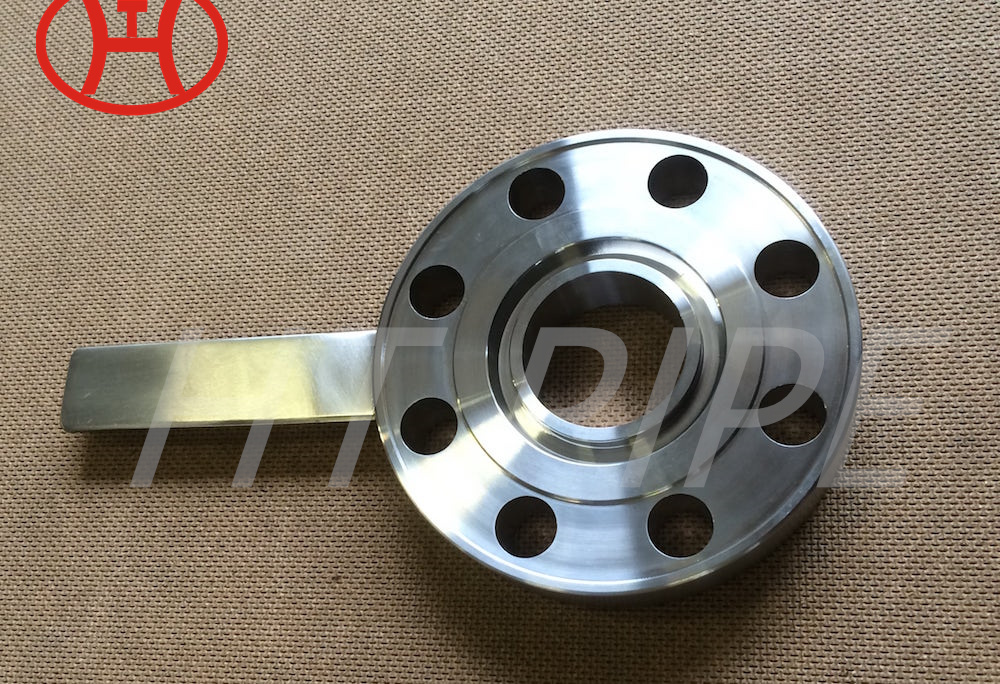

alloy slip-on flange sanitary grade forged backing ring A182 F11 plate flange

Low alloy steel ASTM A182 F11 flanges typically have a total alloy content of 1.5% – 5%. Its common alloying elements are manganese, chromium, silicon, nickel, molybdenum and vanadium. It may contain up to four or five different quantities of these alloys. At the same time, the increased strength of the alloy steel F11 flange may require higher forming pressures. Annealing of SA 182 Gr F11 steel flanges is accomplished by water quenching by thorough immersion at 1725¡ãF – 1850¡ãF (941¡ãC – 1010¡ãC) and can only be hardened by cold work.

Alloy steel A182 F11 flanges are lightweight yet strong. In addition to molybdenum and chromium, it has excellent weldability and resistance to oxidation and oxidation. Meanwhile, Alloy Steel F11 Sliding Flanges are strengthened by full saturating at 1725¡ãF-1850¡ãF (941¡ãC-1010¡ãC), water extinguished and must be solidified by cold working. As with other heat treatment systems, maturation of alloy steel F11 threaded flanges is a cycle/temperature dependent response where temperature is more important than time.