Alloy Steel A335 P5 Seamless Pipe Distributor

A335 steel pipe can be used in NACE applications at high temperature and high pressure in sour environments, can be used in NACE-MRO 175 Sour Service, ideal for creep rupture applications, can handle high temperatures with very low elasticity.

ASTM A335 P9, P11, P22, P91 Pipe specifications

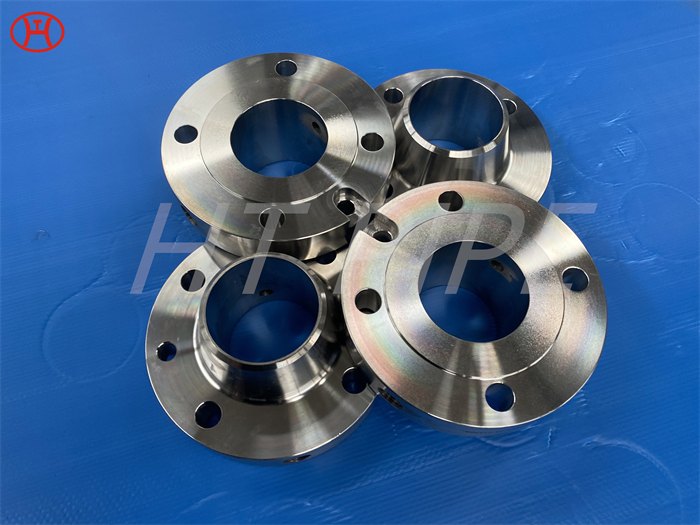

ASTM A335 pipe also named as ASME S/A335 Chrome-Moly pipe, it is a type of seamless pipe used in high temperature environments of 540 – 750 °C. It covers nominal wall and minimum wall thickness pipe that with alloy material. The pipe under this specification shall be suitable for bending, flanging, and all the other similar processing and formations. Although it shall be good for fusion welding. the material could also used to produce pipe fittings like elbow, tee, reducers and flanges.

A335 P5 pipes are also known as ASME SA335 P5 pipes, is a seamless ferritic alloy-steel pipe that mainly has high-temperature applications. The UNS designation for this grade P5 is K41545.

The main composition of ASTM A335 Grade P5 pipes is the addition of chromium and molybdenum. Chromium increase high-temperature strength by enhancing resistance to oxidation resulting in improved Yield, Tensile strength and hardness at room temperature. The addition of molybdenum further increase the strength of the A335 p5 pipe, increased elastic limit, improved wear resistance, good impact values and superior hardness values, A335 p5 pipe also avoids softening of steel, resisting grain growth and makes pipes less susceptible to embrittlement. This allows these pipes to be used in highly corrosive environments. A335 p5 pipe also has high creep and pitting resistance.

Chemical Composition of ASTM A335 Gr. P5 Pipes

| Grade | UNS Designation A | Carbon | Manganese | Phosphorus, max | Sulfur, max | Silicon | Chromium | Molybdenum | Others |

|---|---|---|---|---|---|---|---|---|---|

| P5 | K41545 | 0.15 max | 0.30–0.60 | 0.025 | 0.025 | 0.50 max | 4.00-6.00 | 0.44–0.65 | — |

A New designation established in accordance with Practice E527 and SAE J1086, Practice for Numbering Metals and Alloys (UNS).

D Applies to both heat and product analyses.

Mechanical properties of ASTM A335 Gr. P5 Pipes

| Grade | Tensile strength, min: | Yield strength, min: | Elongation Requirements | |||

|---|---|---|---|---|---|---|

| KSI | MPa | KSI | MPa | Longitudinal | Transverse | |

| P5 | 60 | 415 | 30 | 205 | 30 | 20 |