Alloy Steel ASTM A182 F5 F9 F11 F12 F22 Flange chemical composition

The ANSI B16.5 Alloy Steel Slip On Flange is a flange type that allows the pipes to slip onto the flange and makes the connection in a precise locations.

ASTM A182 F5 FLANGES, ASME SA182 F5 FLANGES, A182 F5 CHROME MOLY FALNGES, A335 P5 PIPE FLANGES, A182 F5 FLANGES CLASS 1, 2, 3 MANUFACTURER IN CHINA.

While ASME SA182 F5 Flanges contain about 0.25% of carbon along with up to 2.0% manganese. ASTM A182 F5 Weldneck Flanges contain trace quantities of alloyants such as niobium, nitrogen, vanadium, copper, nickel, chromium, titanium, calcium, molybdenum, rare earth elements, or zirconium. These A182 F5 Flanges are widely used in various industries and widely appreciated by clients for owning unmatchable characteristics. Offered range supplied in quality assured packaging material. We are offering 24 / 7 manufacturing and delivery worldwide, from a large inventory of Alloy Steel ASTM A182 F9 Flanges such as A182 F9 Alloy Steel Blind Flanges, ASTM A182 F9 Slip On Flanges, Alloy Steel F9 Weld Neck Flanges.

ASTM A182 F5 Flanges is a method of connecting pipes, valves, pumps and other equipment to form a piping system. Flanges CHROME MOLY Flanges also provides easy access for cleaning, inspection or modification. ASTM A182 F5 Socketweld Flanges are usually welded or screwed. ASTM A182 F5 Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal. Chromium-Molybdenum Alloy Steel or Chrome-Moly, CrMo is an alloy steel intended for high temperature and high pressure services. Alloy Steel F5 Chrome-Moly Flange is used in the power generation industry and the petro-chemical industry because of its tensile strength, corrosion resistance and high-temperature strength. Alloy Steel ASTM A182 F5 Chrome-Moly Flange has a better strength to Weight ratio than steel, which enables designers to use thinner wall pipe or smaller diameter tubing to reduce overall weight.

ASTM A182F5 Flange Range

| ASTM A182 F5 Flange Specification | ASTM A182 / ASME SA182 Class 1, Class 2, Class 3 |

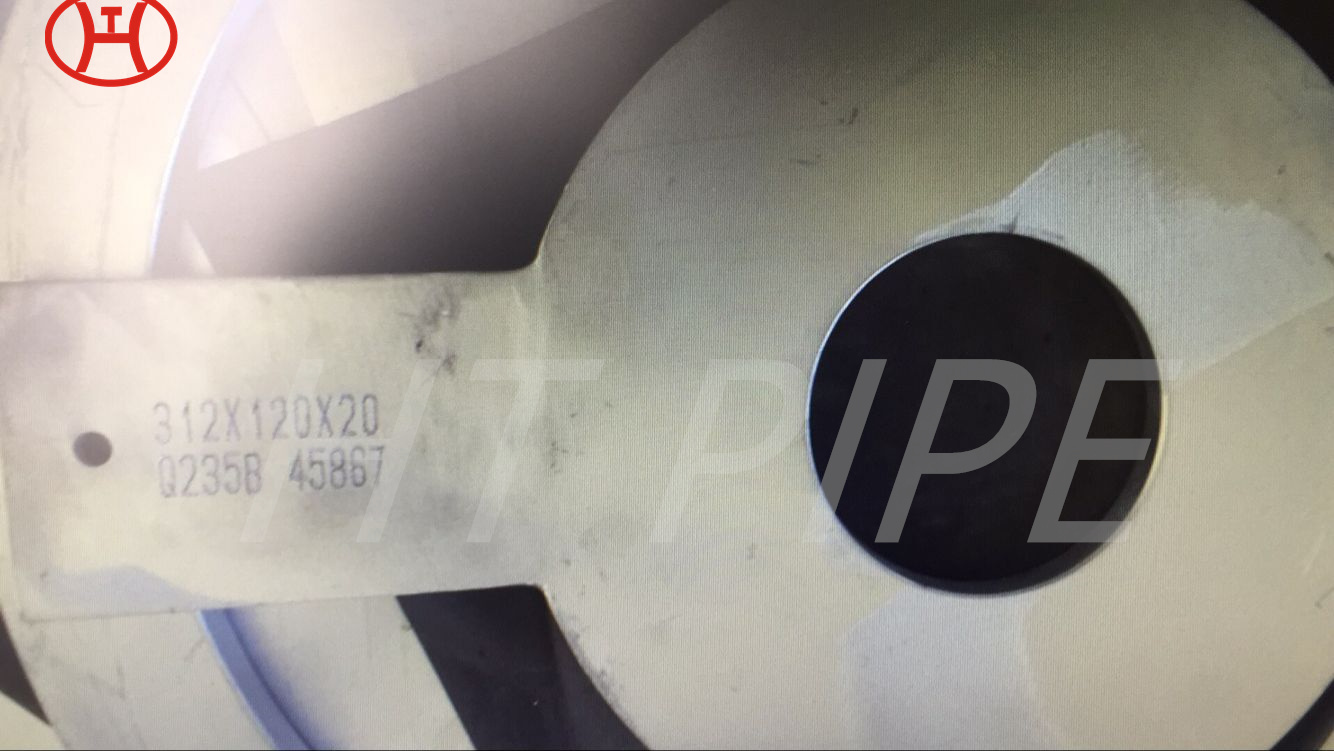

| ASTM A182 F5 Flange Manufacturing Process | Hot Forging / Rolling / Machining |

| ASTM A182 F5 Flange Other Grades | ASTM A182 F5 Flange, ASTM A182 F9 Flanges, ASTM A182 F11 Flange, ASTM A182 F22 Flange, ASTM A182 F9, ASME SA182 F5 Flange, ASME SA182 F9 Flanges, ASME SA182 F11 Flange, ASME SA182 F22 Flange, ASME SA182 F91 Flange, A182 UNS K41545 Flange, A182 UNS K9094 Flange, A182 UNS K11572 Flange, A182 UNS K21590 Flange, A182 K91560 Flange |

| ASTM A182 F5 Flange Outer Diameter | 1/2″ NB TO 64″ NB |

| ASTM A182 F5 Flange Pressure Class | Class 150#, Class 300#, Class 400#, Class 600#, Class 900#, Class 1500#, Class 2500# or As Per Custom Requirement PN 6, PN 10, PN 16, PN 25 and PN 40 etc |

| ASTM A182 F5 Flange Schedule | Sch 10s TO Sch XXS or As Per Custom Requirement |

| ASTM A182 F5 Flange Facing | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| ASTM A182 F5 Flange Dimension | ASME B16.5, ASME B16.47 SERIES A, ASME B16.47 SERIES B, ASME B16.36, BS10, EN1092-1:2013, MSS SP44, ASA, API-605, ISO 7005, ISO 15590-3, DIN 2631–2638, DIN 2573-2576, DIN 2527, DIn 2641-2642, DIN 2565-2566, DIN2502, AWWA, AS2129 TABLE C, D, E, F, J etc.. |

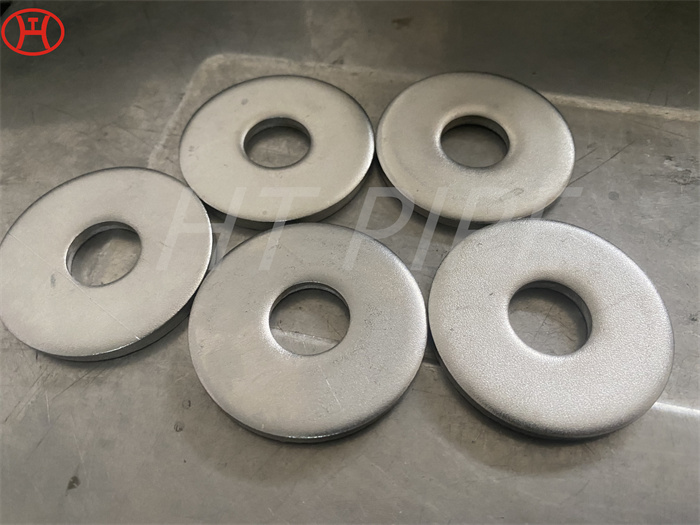

| ASTM A182 F5 Flange Types | Welding Neck Flange, Slip On Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Blind Flange, Orifice Flanges, Plate Flange, Long Welding Neck Flanges, Weldoflange, Nipoflange, Expander Flange, Reducing Flange, WNRF Flange, SORF Flange, SWRF Flange, Custom Flange as per Drawing etc. |

| ASTM A182 F5 Flange Other Testing | NACE MR0175, Ultrasoung TEST, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, HIC, SSC, Sour Service etc. |

| ASTM A182 F5 Flange Value Added Services | Rolling, Drill, Punch, CNC Machining, Sand Blasting, Shot Blasting, Heat Treatment, Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| ASTM A182 F5 Flange Packaging | Loose / Carrate / Wooden Pallet / Wooden Box / Plastic Cloth Wraps |

| ASTM A182 F5 Flange Shipment & Transportation | By Road – Truck / Train Partial Load, Full Load, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| ASTM A182 F5 Flange Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved ETC |