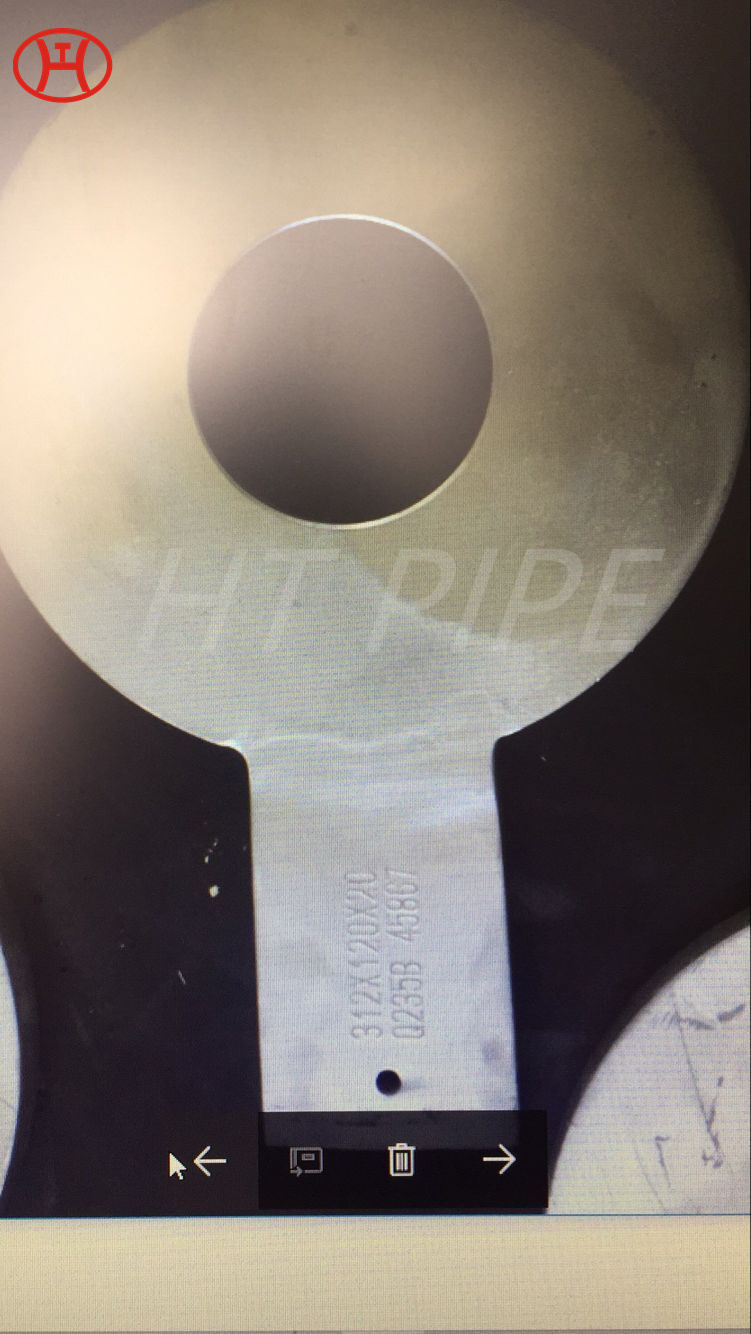

Alloy steel plate 42crmo4 4140 sheet

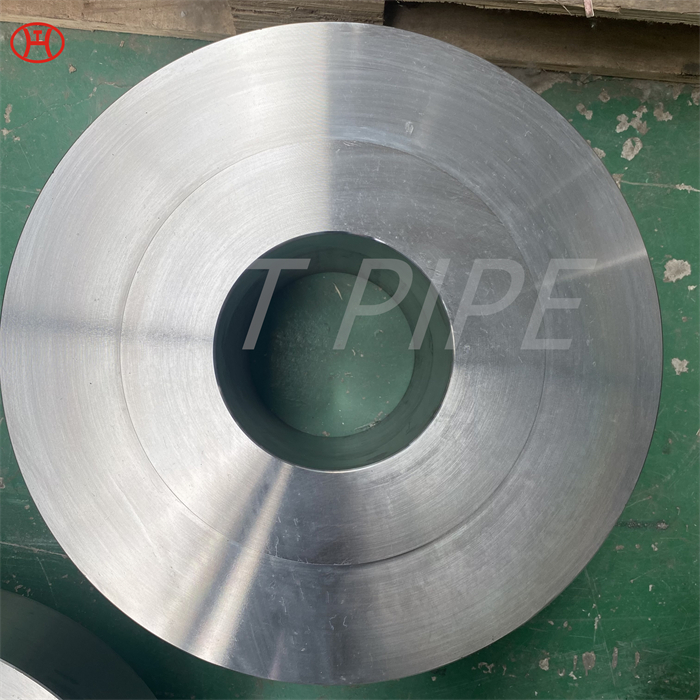

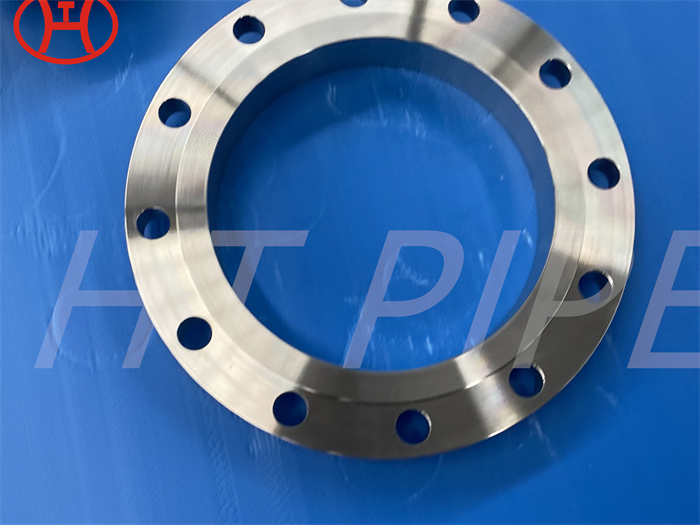

Too many good properties found in the same product just because of better sheet production. These are high tensile strength, good dimensional accuracy, surface finish, flexibility and durability, withstand heavy loads, strong construction and corrosion resistance. Resistance to corrosion, stress corrosion cracking, crevice corrosion cracking, oxidation/pitting corrosion makes it suitable for a variety of applications.

Supplier of 4140/42CrMo4 Plate, En19 Plate/42CRMO4 Grade Plate, DIN 42CrMo4 1.7225 Alloy Steel Plate & Sheet

We are 42CrMo4 plate stockholders and 4140 plate suppliers who can deliver to anywhere in the world. As a quality alloy steel grade 42CrMo4 is commonly supplied quenched and tempered (QT) which offers good high tensile properties. 4140 sheet is characterised by its good ductility and shock resistant properties that combines with good wear resistance. Suitable for nitriding which gives a shallow depth wear resistant case to provide maximum wear and abrasion resistance. Also suitable for induction or flame hardening which can give a case hardness of 50 HRc or higher.

On the hardenability of steel, 42crmo4 heat treatment has good strength and good comprehensive mechanical properties, good manufacturability, high yield. The highest temperature is 427 degrees Celsius. 42crmo4 strength, high hardenability, and good toughness, quenching deformation of small, high temperature creep rupture strength, and high. 42CRMO4 Grade Plate is used for manufacturing forgings with higher strength and larger tempering cross-section than 35CrMo steel, such as big gear for locomotive traction, supercharger drive gear, rear axle, connecting rod and spring clamp with great load, also DIN 42CrMo4 1.7225 Alloy Steel Plate can be used for drilling pipe joint and fishing tool of oil deep well below 2000m, and can be used for bending machine mold, etc.

Chemical Composition

| 42CrMo4/1.7225 | C | Mn | Si | P | S | Cr | Mo |

| 0.38-0.45 | 0.60-0.90 | 0.40 max | 0.035 max | 0.035 max | 0.90-1.20 | 0.15-0.30 |

Relevant Specifications and Equivalents

| BS EN 10083 | Material No. | DIN | ASTM A29 | JIS G4105 | BS 970-3-1991 | BS 970-1955 | AS 1444 | AFNOR |

| 42CrMo4 | 1.7225 | 38HM | 4140 | SCM440 | 708M40 | EN19A | 4140 | 42CD4 |

If you are a Spanish user, you can visit this page:https://www.htpipe.es/aleacion-4140.html