Alloy steel plug ASTM A182 F22 3000#

Hex bolts are used to fasten two or more parts together to form an assembly either because it cannot be manufactured as a single part or to allow for maintenance and repair disassembly. By definition “A Bolt is a headed and externally threaded mechanical device designed for insertion through holes in assembled parts to mate with a nut and is normally intended to be tightened or released by turning that nut.” When used with a preformed internally threaded (tapped) hole, the hex bolt’s head is turned to tighten, which technically makes it a screw (see our Tech Data section for a discussion regarding the differences between bolts and screws). Hex bolts are also known as: hex head bolts, cap screws, hex cap screws, hex head cap screws, machine bolts, hex machine bolts, hex head machine bolts and, if fully threaded, tap bolts, hex tap bolts and hex head tap bolts. A hex bolt is often differentiated from a hex cap screw by its underhead bearing surface: if it has a circular boss, called a washer face, it’s a hex cap screw¡ªif it doesn’t then it’s a hex bolt.

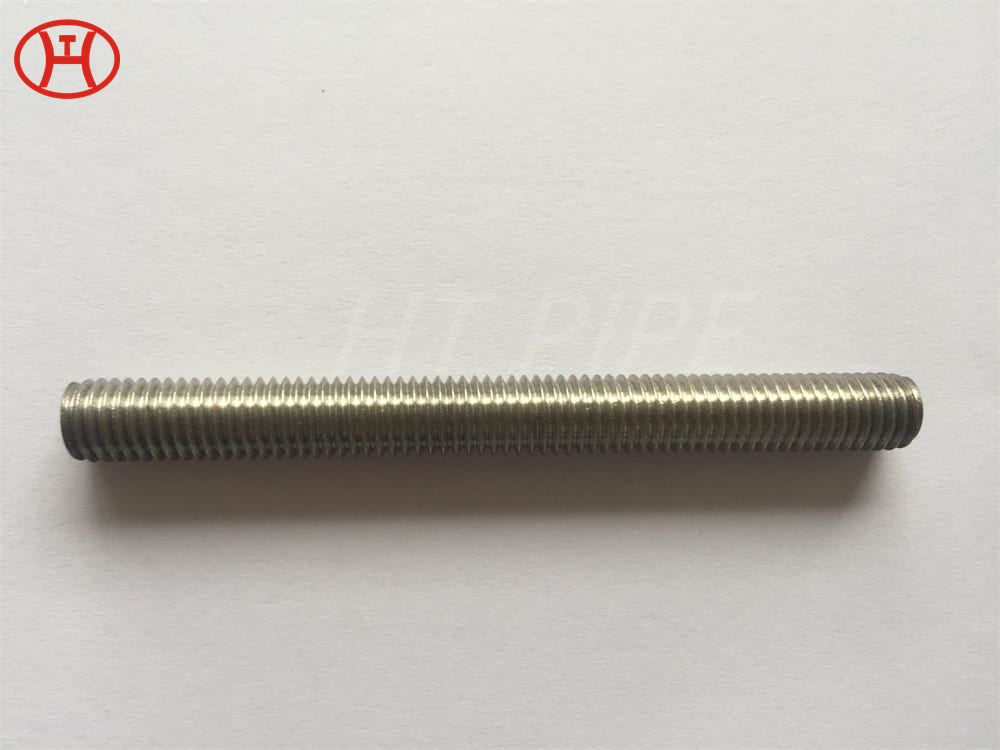

Hex bolts have either cut or rolled screw threads that comply with the Unified system: UNC (Unified National Coarse) and UNF (Unified National Fine). Coarse threaded fasteners have fewer threads per inch than fine threaded fasteners because coarse threads are farther apart. For example, a coarse threaded 1/4″ hex bolt has 20 threads per inch whereas a 1/4″ fine threaded bolt has 28 threads per inch. Consequently, the larger the number of threads per inch, the finer the thread. Also, smaller sizes have more threads per inch than larger sizes¡ªa 1 1/2″ UNC bolt, for example, has just 6 threads per inch. Coarse bolts are more common, and there are advantages and disadvantages to both coarse and fine threads. (For more information about threads, visit our Tech Data section.) Short lengths are fully threaded while longer lengths follow a standard formula: for bolts 6″ and shorter, the threaded length is two times the basic thread diameter plus 1/4″, and for lengths greater than 6″, two times the diameter plus 1/2″. This, however, is the minimum threaded length and manufacturers may thread the bolt substantially more. In addition, some longer bolts are fully threaded and are often called tap bolts. Table 1 summarizes the number of threads per inch for the various sizes. Right-hand threads are standard (turn clockwise to tighten). Hex bolts are not pointed whereas hex cap screws have a chamfered (beveled) point to protect the first thread from damage and to facilitate entry into an internally threaded part such as a nut or tapped hole.