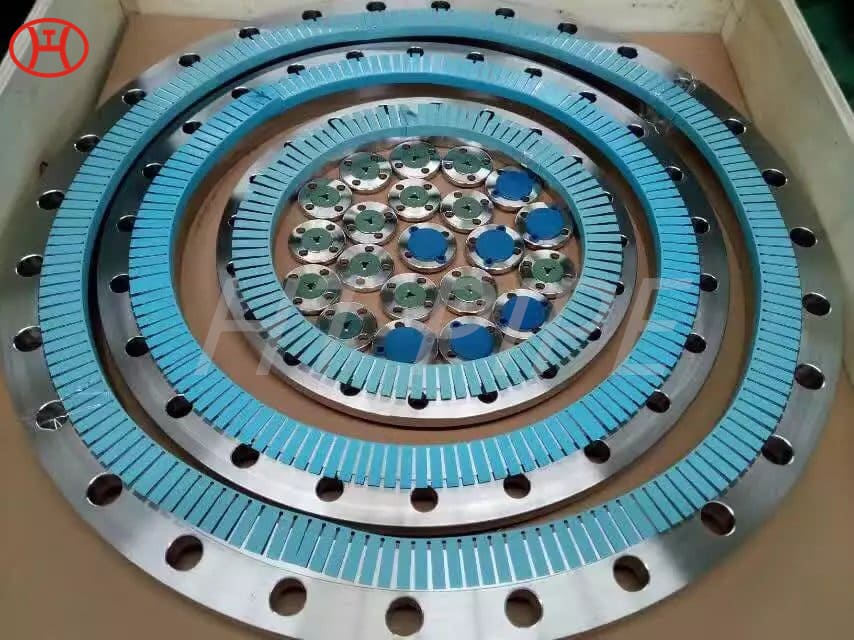

alloy tapped flanges, pipe fitting flanges parts A182 F9 plate flange

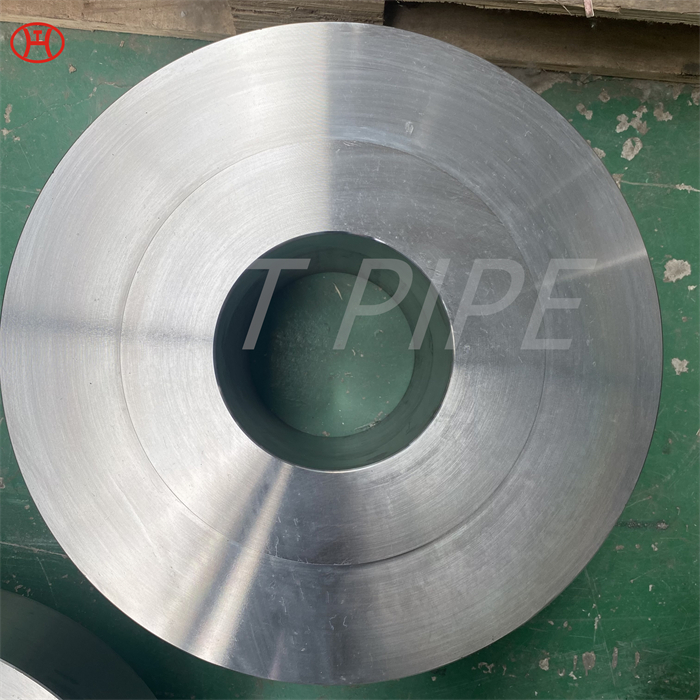

The production of ASME SA182 F9 flanges will be done using alloys with lower carbon content. Reducing the carbon content in these alloys reduces the formation of carbide precipitates. This basically means that alloy steel F9 flanges will no longer be susceptible to intergranular corrosion in the heat affected weld zone.

The high chromium content in ASTM A182 Gr F9 flanges combined with molybdenum in the alloy increases its toughness. Not only is this material durable, but its corrosion resistance surpasses that of carbon steel, which has properties ranging from low to none. Meanwhile, ASTM A182 F9 flanges are made of corrosion-resistant, strong, and tough steel that can be used in many different industrial applications. There are threaded, welded, fabricated, threaded and ASTM A182 F9 forged fittings available in nominal bore sizes from ?” to 48″. Fittings are also available in different pressure ratings and pressure numbers. Pressure ratings for SA 182 Gr F9 pipe flanges vary depending on application requirements. This material is available in grades 150 to 2500 and pressure numbers PN6 to PN64.