Annealing process of316 Stainless Steel Socket Threaded Fittings NPT 1.4436 coupling

Annealing is a specific process of heat treatment that alters the properties of metal. While there are many different types of heat treatment, annealing is popular because it increases ductability and reduces hardness.

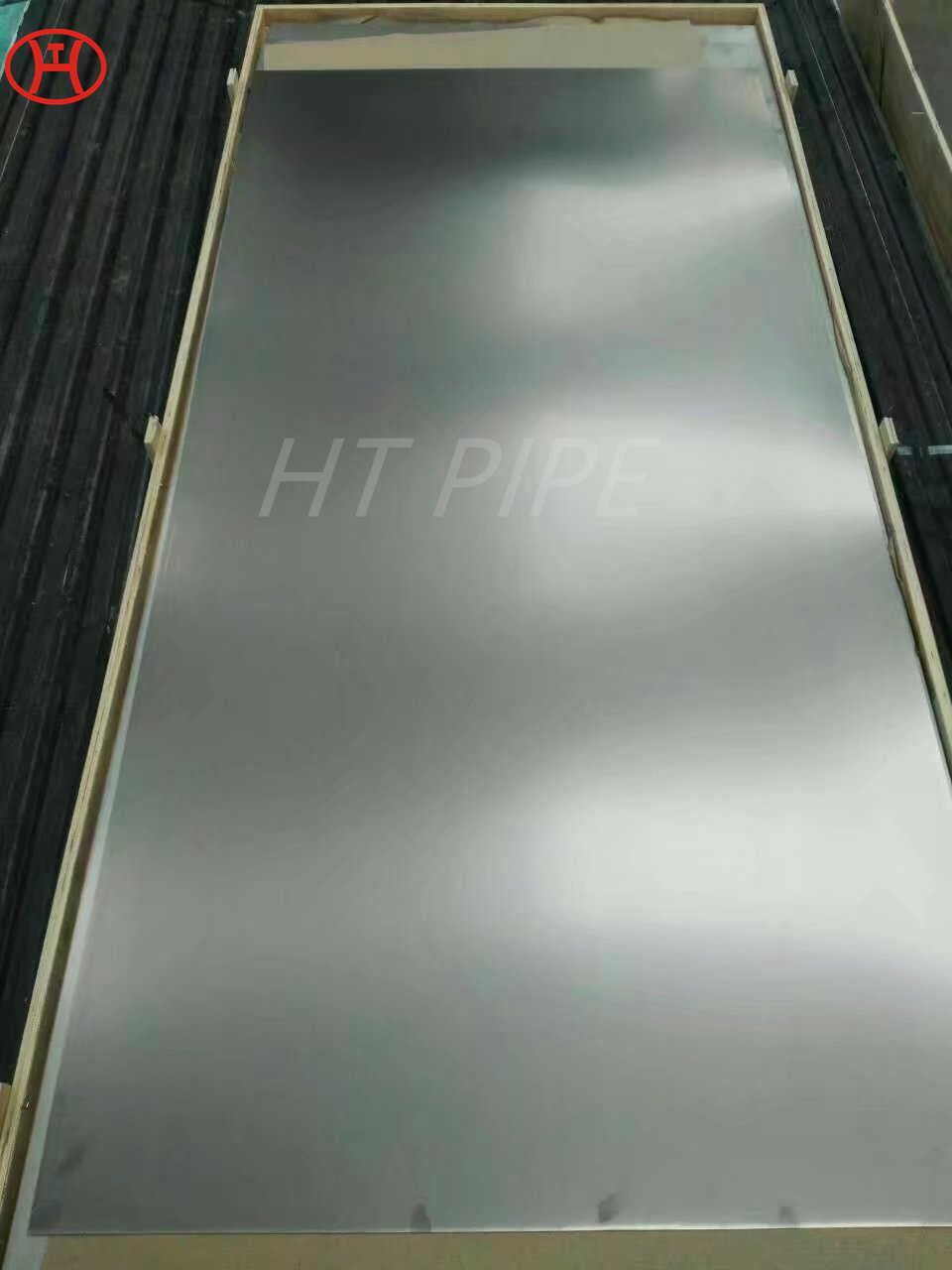

Sheet metals, such as cold rolled steel sheet and galvanized steel sheet, are annealed because the process of cold rolling creates too much hardness for further processing. Annealing restores their ductility and formability, which allows for further bending, punching, forming/stretching or cutting without cracking or losing dimensional stability.

Cold-finished bar and metal wire often undergo annealing because the process of drawing them through a die causes stresses in their grains. This increase in the strength and brittleness of the metal is called work hardening. Annealing removes this work hardening stress, which can facilitate additional drawing steps or allow for specific mechanical properties in the finished steel. Commonly specified half-hard and dead-soft conditions are a result of controlling the final mechanical properties through the annealing process.

Aluminum is commonly annealed to allow for extreme forming and drawing operations that would otherwise cause cracking or tearing in the metal. Deeply drawn parts are often specified as fully annealed, tempered or dead soft product.

Annealing is also used to make materials more uniform if welding has led to residual stress in the heat affected zone.

How Does Annealing Compare to Normalizing?

Unlike annealing, normalizing is the process of increasing hardness. To normalize the metal, you increase the temperature of the material above the austenitic range and then cool it in room temperature air. Austenization means to heat the metal to a temperature at which its crystal structure changes from ferrite to austenite. If you¡¯re looking for a softer, more ductile metal, choose annealing. If you¡¯re looking for a harder, less ductile metal, choose normalizing. Either way, both heat treatments lead to metals with less stress and more machinability.