asme b16.5 carbon steel bw rf pipe flange

Generally speaking, the carbon-free content of carbon steel pipe flanges is lower than that of molten flanges. They don’t oxidize very quickly. They are flat and fairly light in construction, and the fused flanges have excellent mechanical properties. Improper forging methods often result in broad or irregular grains; hardening cracks and forging are taller than cast flanges.

A carbon steel pipe flange is an external or internal edge, or a rim (lip), for power, such as an iron plate flange, such as an I-beam or a T-beam; or for attachment to another component, such as a flange at the end of a screw, a steam lever, etc., or a camera lens mount; or a railcar flange or tram wheel flange. Therefore, flanged wheels are wheels on one side with a flange to prevent the wheels from slipping off the tracks. The word “flange” is often used for the shape of flanges for a kind of device. Flanged pipes may be quickly installed and disassembled.

Carbon steel, or medium carbon steel, is an element of metal. It is a mixture of the iron and carbon components. Many components are too small to influence its properties in amounts. In pure carbon steel the only other elements permitted are: manganese (1.65 percent max), silicon (0.60 percent max) and copper (0.60 percent max). With more carbon content these carbon steel pipe flanges achieve strength and toughness but are less ductile and tougher to weld. Higher carbon content decreases the melting point of the flange, and its total temperature tolerance.

Carbon steel pipe flangess are less carbon-free than molten flanges in general. They don’t oxidize quickly. They are flat, the construction is fairly lightweight and the molten flange has superior mechanical properties. Improper methods of forging can often result in broad or irregular grains; it is higher to harden cracking and forging than the casting flange.

According to the manufacturing cycle, the forging flange has some operational theory in the carbon steel flanges. The production method and the usage of the carbon steel flange provide certain operating theory. Its basic philosophy is to use the insulation efficiency of the carbon steel flange isolating gasket. Insulation with high duty carbon steel flange, carbon steel flanges on both sides of the electrical insulation flange of the plant. Mary Iron and galvanized tubing, which is heavier than concrete, are widely used (canned) than steel. Low carbon steel from Stainless Steel Flanges Factories In China, refining of cast carbon steel flanges, forging and grinding, rivets, screws, brace production such as low carbon steel flanges is used.

Low Temp Carbon Steel Flange Specification

| Specifications | ASTM A182 / ASME SA182 |

| CS Flange Standard EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| CS Flanges Standard DIN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| PN6 PN10 PN16 PN25 PN40, PN64 | |

| Low Temp Carbon Steel Flanges Standard JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Quenching Low Carbon Steel Flanges Standards | ANSI/ ASME |

| B16.5 | |

| B16.47 Series A & B | |

| B16.48, BS4504 | |

| BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. | |

| Plain Carbon Steel Flanges Standard ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Steel Low Carbon Flanges Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

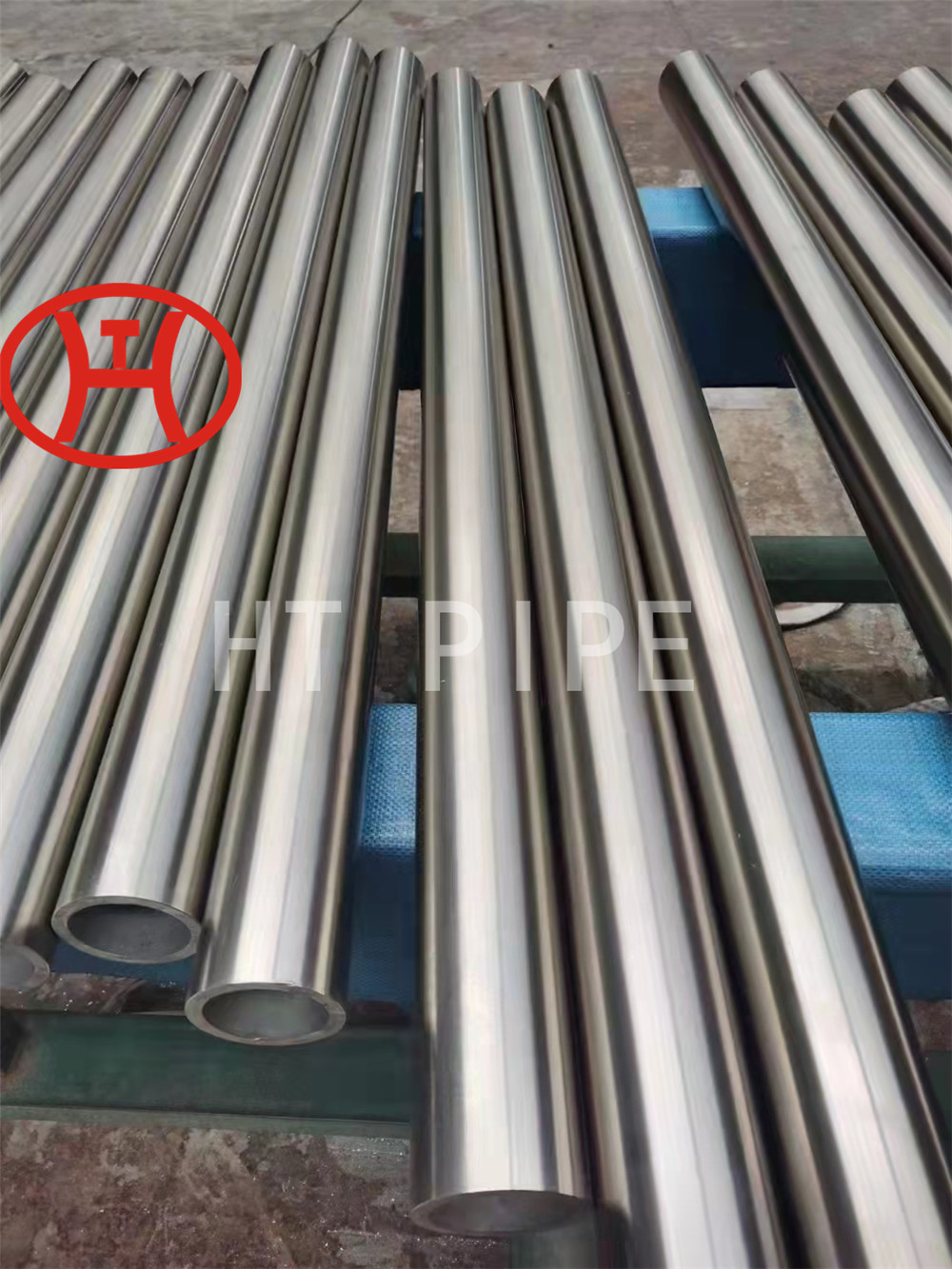

| ASME B16.5 Steel High Carbon Flange size range | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Low Carbon Steel Flange supporting material | Gasket, Ring Joint, Flange Bolts |

| Medium Carbon Steel Pipe Flanges Test Certificates | EN 10204/3.1B |

| Raw Materials Certificate | |

| 100% Radiography Test Report | |

| Third Party Inspection Report, etc | |

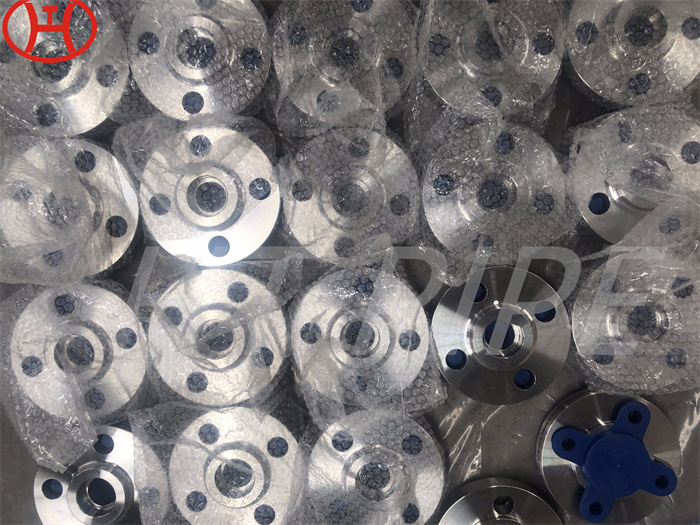

| Quenching Carbon Steel Flanges Production technique | Forged, Heat treated and machined |

| Manufacturer of | Galvanized Carbon Steel Forged / Threaded / Screwed / Plate Flange |

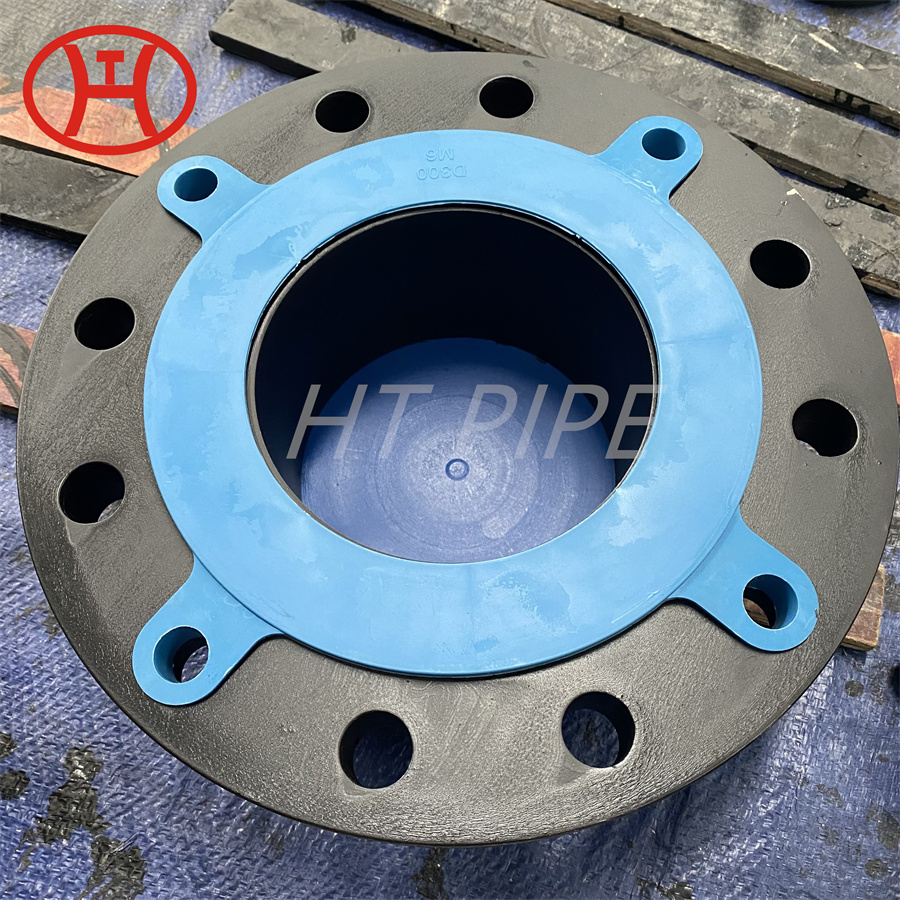

| Most common types of Low Temp Carbon Steel Flanges | Black Carbon Steel Weld Neck Ring Flanges (WNRF) |

| CS Blind Ring Flanges (BLRF) | |

| Galvanised Carbon Steel Slip-On Ring Flanges (SORF) | |

| Killed Carbon Steel Socket Weld Ring Flanges (SWRF) | |

| Normalized Carbon Steel Threaded Ring Flanges | |

| Quenching High Carbon Steel Lap Joint Ring Flanges (LJRF) | |

| Steel Grades Carbon Ring Type Joint Flanges (RTJF) | |

| Steel High Carbon Flange Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Large Male-Female (LMF), Flat Face (FF), Small Male-Female (SMF), Lap-Joint Face (LJF), Small Tongue, Large Tongue & Groove, , Groove |

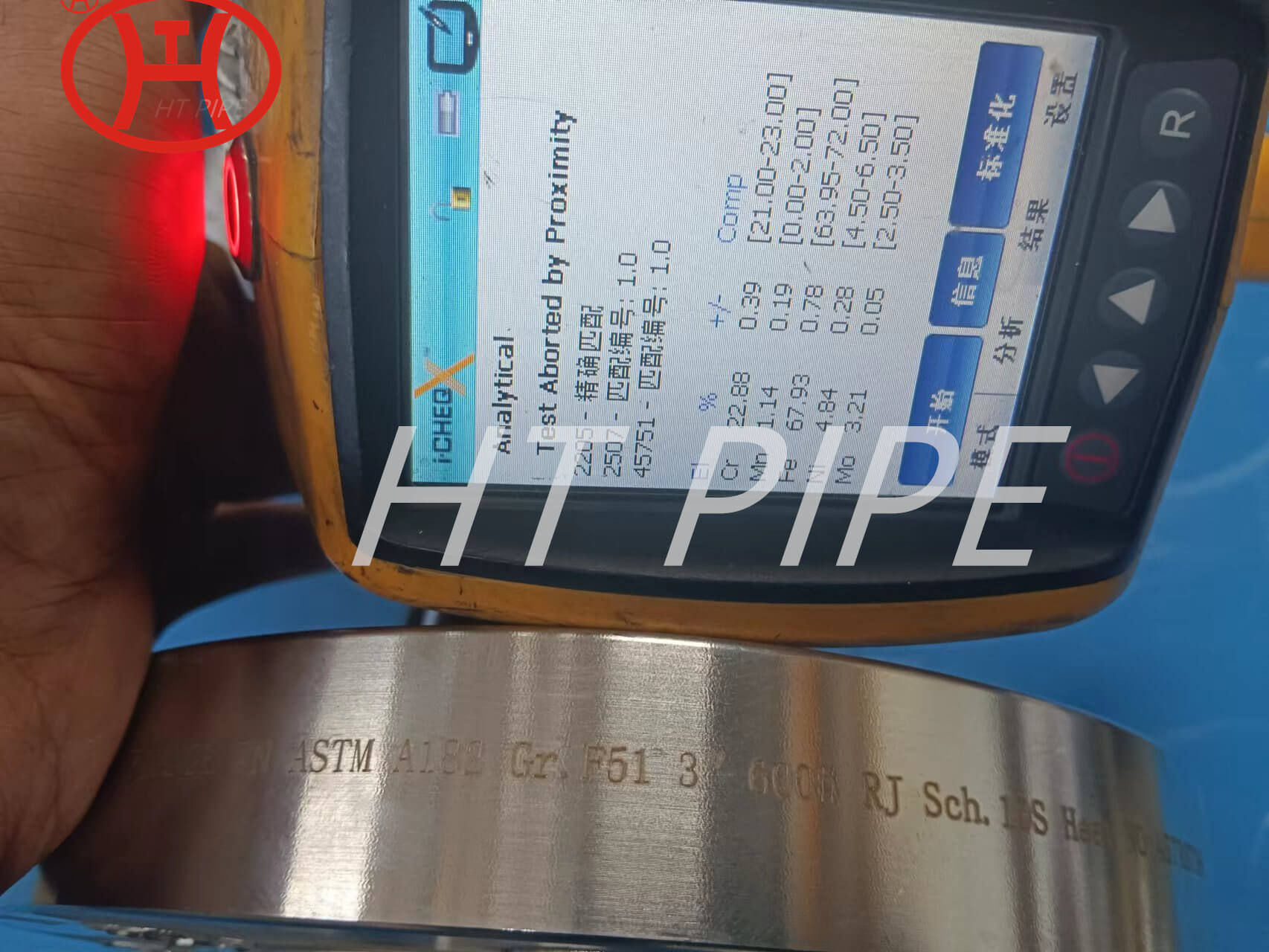

| Normalized Carbon Steel Flange Test | X-ray detector, Direct-reading Spectrograph, Hydrostatic testing machine, UI trasonic flaw detector, Magnetic particle detector |

| Equipment for Nace Mr0175 Carbon Steel Flange | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Special manufacturing design of Carbon Steel Flanges | As per your drawing |

| AS, ANSI, BS, DIN and JIS | |

| 15 NB (1/2″) to 200 NB (8″) | |

| Equal and Reducing Configurations | |

| Specialized manufacturer of | Galvanized Carbon Steel Rtj Flanges |

| Killed Carbon Steel Pn16 Flanges | |

| DIN 2566 pn16 | |

| DIN 2566 en 1092 1 | |

| Low Carbon Steel DIN 2566 pn10 | |

| CS Weld Neck Flanges | |

| Low Carbon Steel Threaded Flanges | |

| Steel High Carbon Slip-On Flanges | |

| Low Temp Carbon Steel Sorf Flanges | |

| Plain Carbon Steel Blind Flanges | |

| Quenching Low Carbon Steel Table Flanges | |

| Low Temp Carbon Steel Socketweld Flanges | |

| Plain Carbon Steel Plate Flanges | |

| Galvanized Carbon Steel Lap Joint Flanges | |

| Black Carbon Steel Loose Flanges | |

| ASME B16.36 Steel Grades Carbon Orifice Flanges | |

| AS 4087 Water Flanges | |

| Low Carbon Steel Large Diameter Flanges | |

| Carbon Steel Grade Flange Origin | Indian / West Europe / Japan / USA / Korean (Strictly No china Plain Carbon Steel material) |

| Carbon Steel Flanges Standard | ANSI Flange |

| JIS/ KS Flange | |

| API 6A Flange | |

| ASME Flange | |

| DIN Flange | |

| EN1092-1 Flange | |

| UNI Flange | |

| BS4504 Flange | |

| GB Flange | |

| AWWA C207 Flange | |

| GOST Flange | |

| PSI Flange | |

| Application & uses of Carbon Steel Flanges | Quenching High Carbon Steel Flange are mainly used in Chemical, Oil & Gas, Power, Nuclear power (mostly seamless), Heavy oil refineries, Bitumen upgraders, Petrochemicals and acids, Construction, Gas, Metallurgy, Shipbuilding industries & others. |